Distributor

A material distributor and material storage technology is applied in the field of shaft lining construction devices, which can solve the problems of high shaft lining construction time, high labor cost, and large construction investment, and achieve the effects of saving installation time, improving pouring quality, and avoiding wasting materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

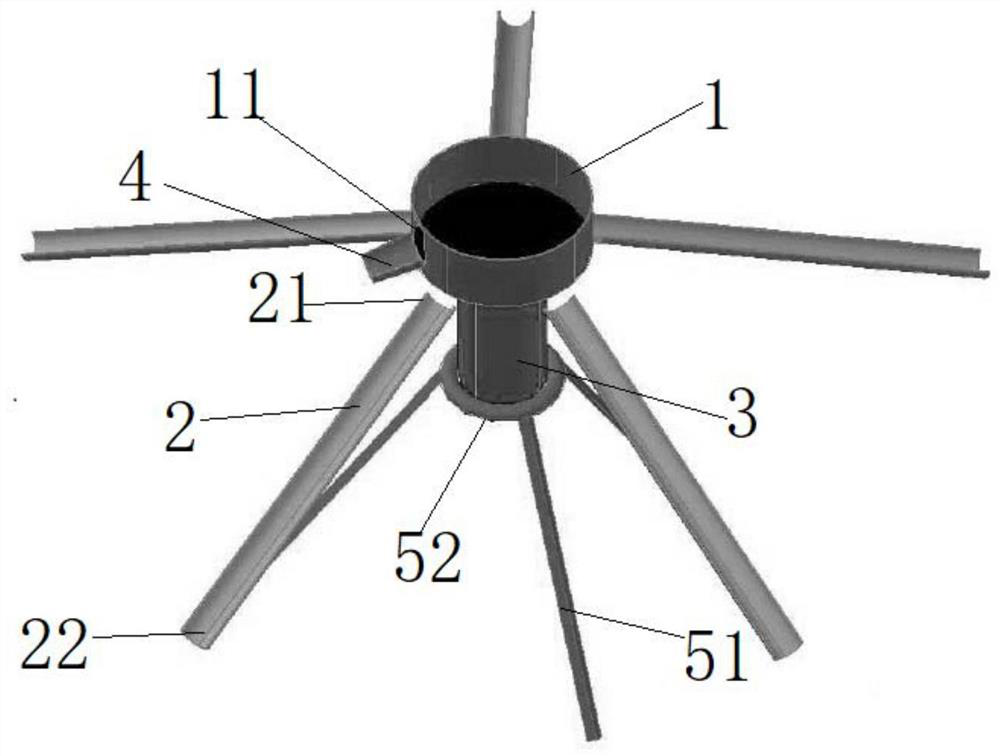

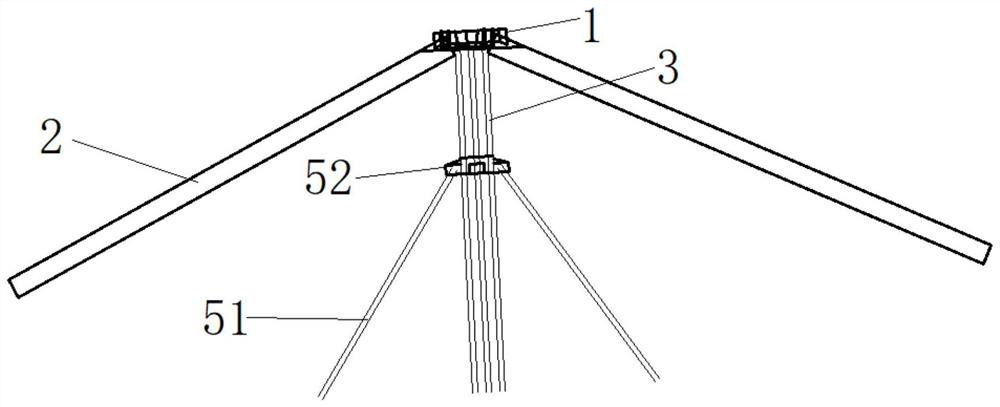

[0033] This embodiment provides a feeder, such as figure 1 and figure 2 As shown, it includes a storage unit 1 and at least three unloading units 2 .

[0034] Wherein, the material storage part 1 has an accommodating chamber suitable for storing materials; at least three blanking parts 2 are spaced and evenly distributed outside the outer circumference of the material storage part 1, and the unloading part 2 has a cavity facing outwards and outwards from the accommodating chamber. A conveying channel extending downwards; the top and the bottom of the blanking part 2 are respectively provided with a socket 21 and a discharge port 22; The socket port 21 can communicate with at least one feeding port 11 .

[0035] When working, the distributor is placed in the middle of the shaft, and the three feeding parts 2 are evenly arranged along the circumference of the inner wall of the shaft. In the accommodating chamber, the socket 21 is connected to the feeding port 11, and then th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap