Flattening and coating integrated machine for concrete pavements

A technology of concrete pavement and all-in-one machine, applied in the direction of roads, roads, road repairs, etc., can solve the problems of affecting work efficiency, wasting labor, and long construction period, and achieve reasonable functional structure, improved structural rationality, and reasonable water tank structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

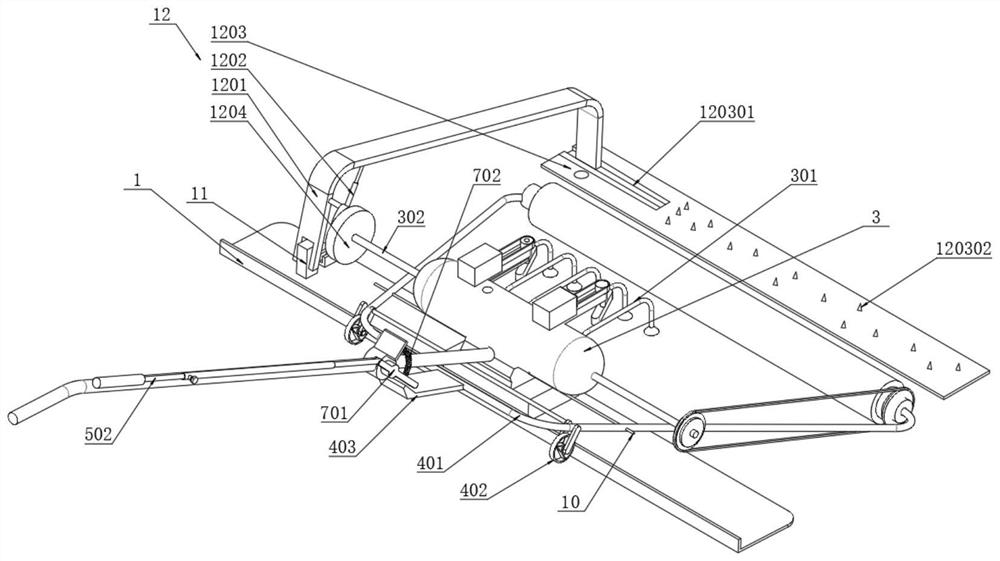

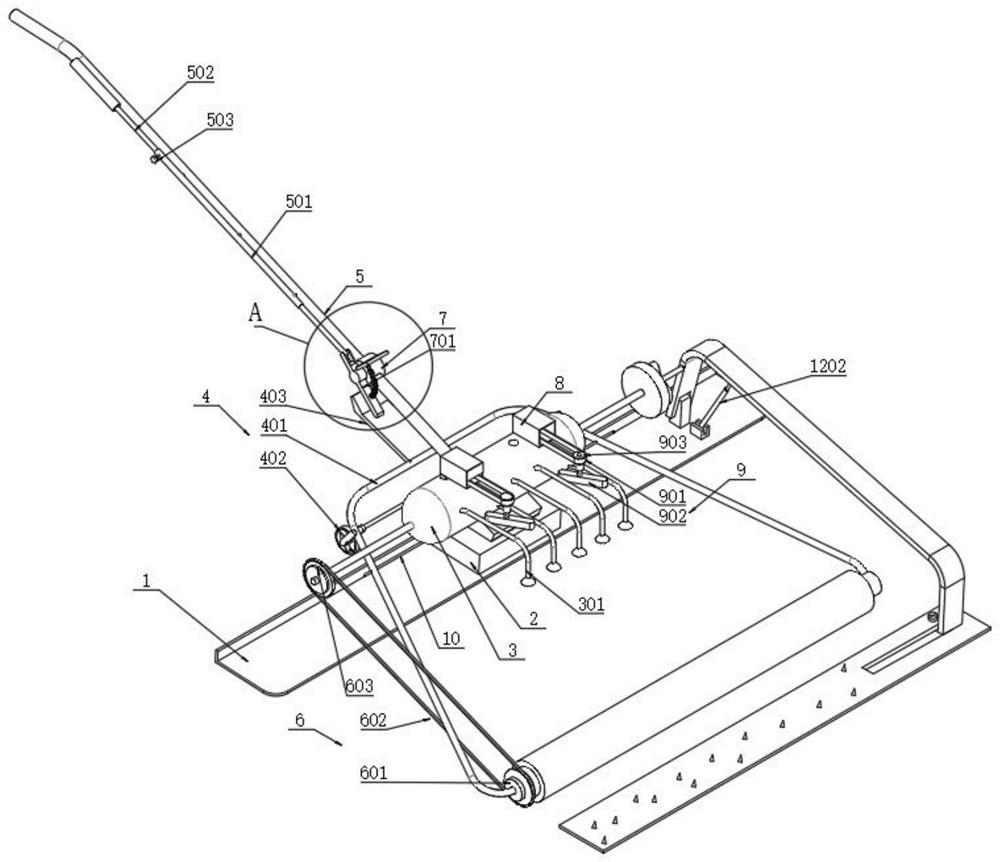

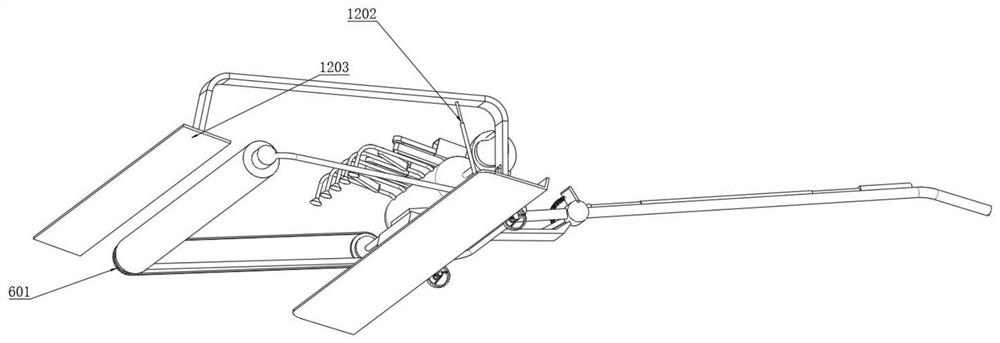

[0031] The following is attached figure 1 - Figure 8 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

[0032] The all-in-one machine for leveling and covering concrete pavements includes a leveling plate 1, a sprocket mechanism 6 and a beating mechanism 12. The top surface of the leveling plate 1 is provided with a mounting seat 2. In order to improve the functionality of the device, as figure 1 , figure 2 Shown, also be fixed with the water tank 3 that is connected with external pressure water source water supply on the top surface of mounting seat 2, the rear side of water tank 3 is provided with a row of shower heads 301, in actual use, the external pressure water source (by the water pump of prior art Provided, when the water pump injects water inwardly, a pressure water source) is injected into the water tank 3 through the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com