A two-speed gearbox with Simpson planetary gear structure and power transmission logic

A planetary gear, Simpson-style technology, applied in gear transmissions, vehicle gearboxes, components with teeth, etc., can solve problems such as inability to effectively improve driving acceleration, limited efficient working range of motors, and impact on drivers' subjective feelings, etc. Achieve the effect of good vehicle starting performance, strong acceleration performance and high driving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

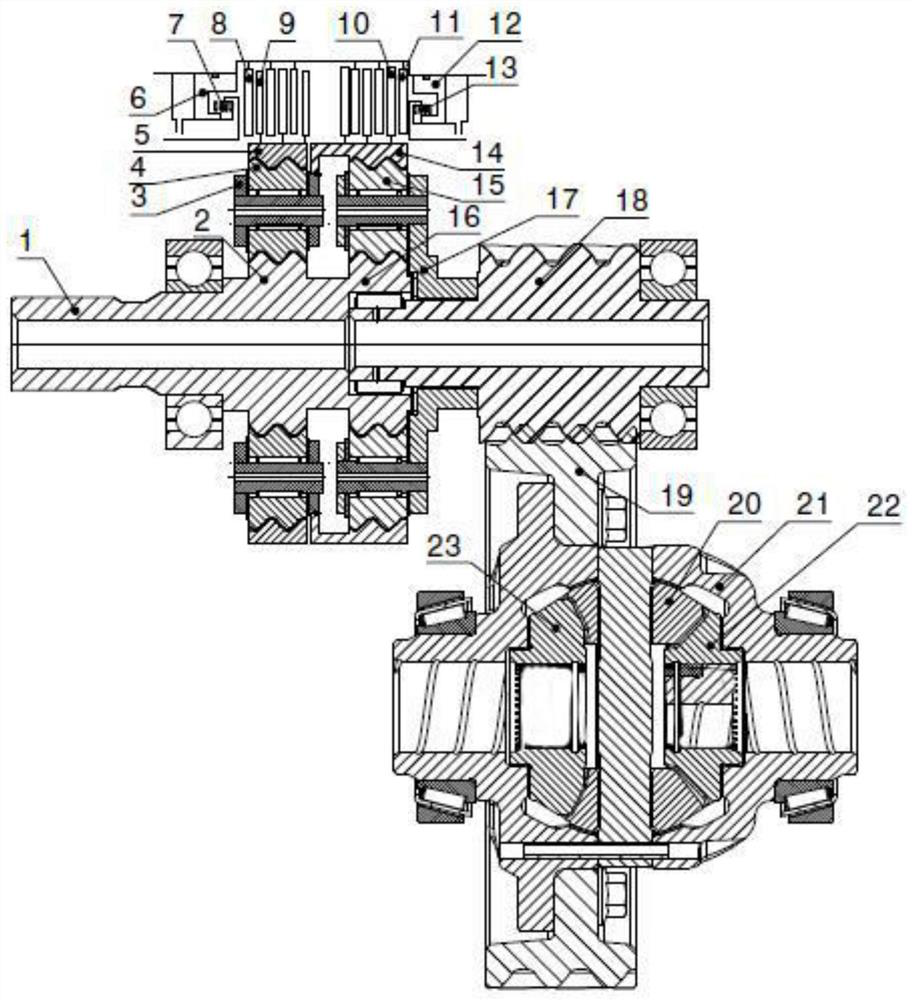

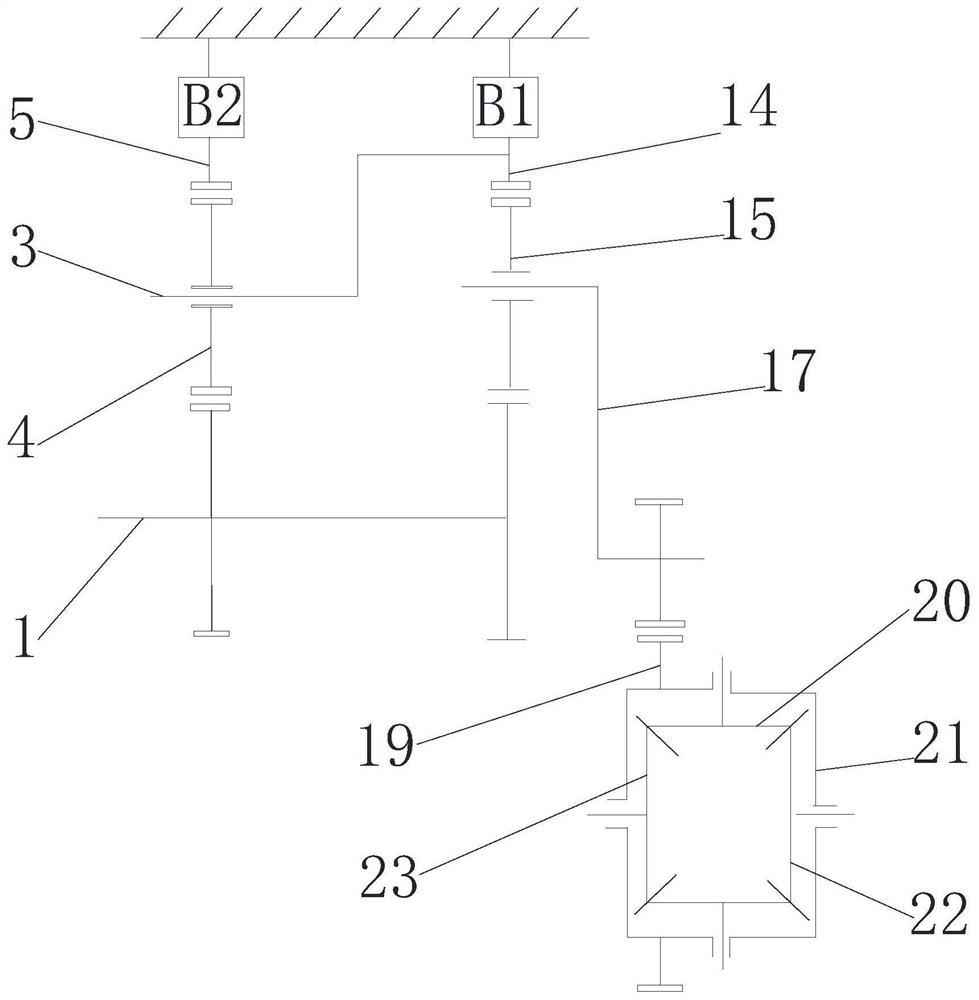

[0036] see figure 1 and figure 2, a two-speed reduction box with a Simpson-type planetary gear structure, including an input shaft 1, on which a planetary gear assembly is installed; the planet carrier 17 of the planetary gear assembly is connected to the intermediate shaft gear 18, and the hole of the input shaft 1 is connected to the middle Shaft gear 18 is connected with needle bearing; intermediate shaft gear 18 meshes with differential ring gear 19; differential gear ring 19 is connected with differential case 21 through bolts; The surface of the side gear 22 and the left side gear 23, the surface of the right side gear 22 and the left side gear 23 are meshed with a differential planetary gear 20, and the differential planetary gear 20 is installed inside the differential case 21 , preferably, the planetary gear assembly includes sun gear two 2 and sun gear one 16; both sun gear two 2 and sun gear one 16 are installed on the input shaft 1; sun gear two 2 and sun gear on...

Embodiment 2

[0048] Please refer to Table 1: Table 1 is a schematic diagram of the principle of a two-speed gearbox

[0049] Condition Brake B1 Brake B2 1st gear lock up disengage 2nd gear disengage lock up Neutral disengage disengage Reverse gear (motor reverse rotation) lock up disengage

[0050] In this embodiment, the input torque is connected between the motor and the input shaft 1, and the output torque is output through the planet carrier one 17, and transmitted to the differential ring gear 19 through the built-in main reduction gear, and then through the differential case 21 and the differential gear. transmission planetary gear 20 to the left side gear 23 and the right side gear 22;

[0051] When the first gear is engaged, the built-in brake B1 is locked, the inner ring gear 14 is fixed to the planet carrier 2 3, and the torque is transmitted from the input shaft 1 to the planet gear 1 15, and then output by the planet carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com