A device and method for measuring yarn torque through a free rotor

A rotor and yarn technology, applied in the field of detection devices, can solve the problems of high cost, complex detection process, low detection accuracy, etc., and achieve the effects of reducing errors, accurate torque, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

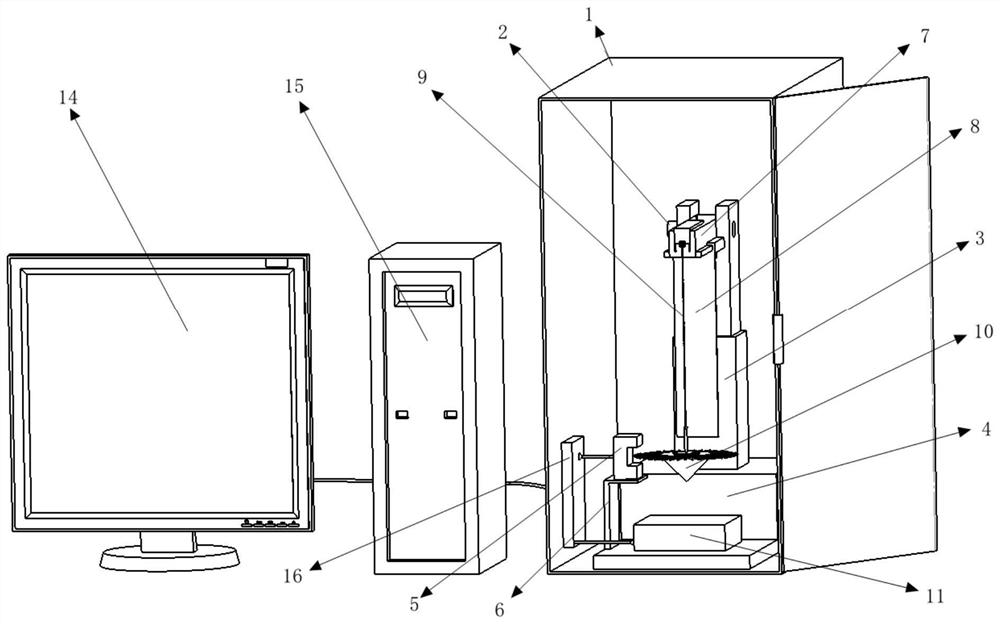

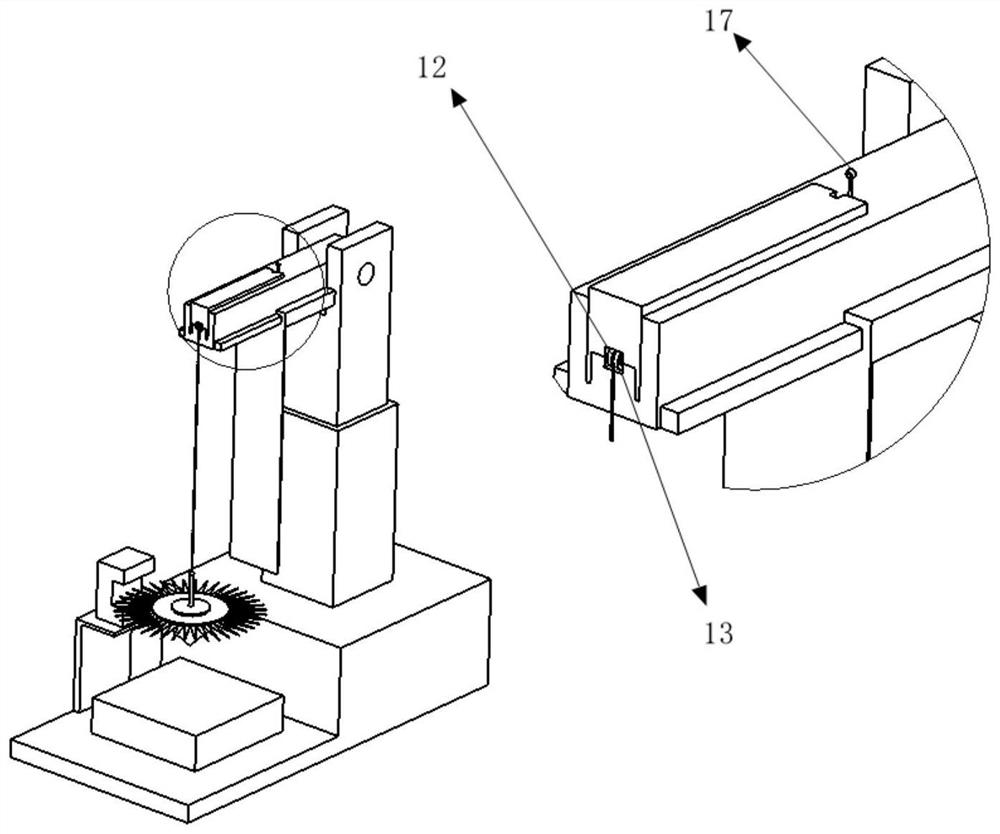

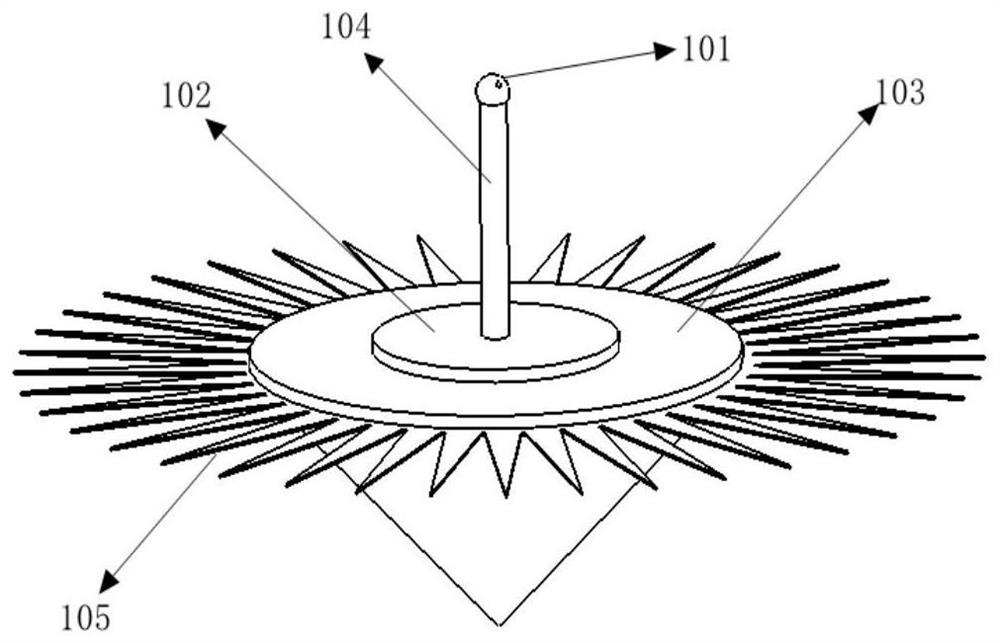

[0037] See Figure 1 to 3 According to an apparatus for measuring yarn torque by a free rotor comprises a casing 1, a computer assembly, and a torque detecting member, a fixing member, a fixing member, a fixing member, a fixing member, a fixing member, a fixing member. The torque detecting member is composed of a rotor 10 and a sensor 5 having a fixed rotational inertia, and the yarn 9 passes through the circular hole 101 on the positioning member 104 through the striking 12 of the beam 7 traction after pulling the wire groove. 13 is fixed to the fixed ring, placing the photographic door sensor 5 on the side of the rotor 10, and the angular velocity when the rotor assembly is rotated.

[0038] The box 1 is a transparent glass box facilitating the internal detection situation in real time, and is provided on one side, which is convenient to open, to ensure the selection of the detecting device, to avoid the influence of the external environment to ensure stable operation of the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com