5G-based cloth defect detection method and system

A defect detection and cloth technology, applied in optical testing defect/defect, measuring device, image data processing, etc., can solve the problems of difficulty in identifying the thickness of dark and light colors, various colors of cloth, and great visual damage to inspection workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

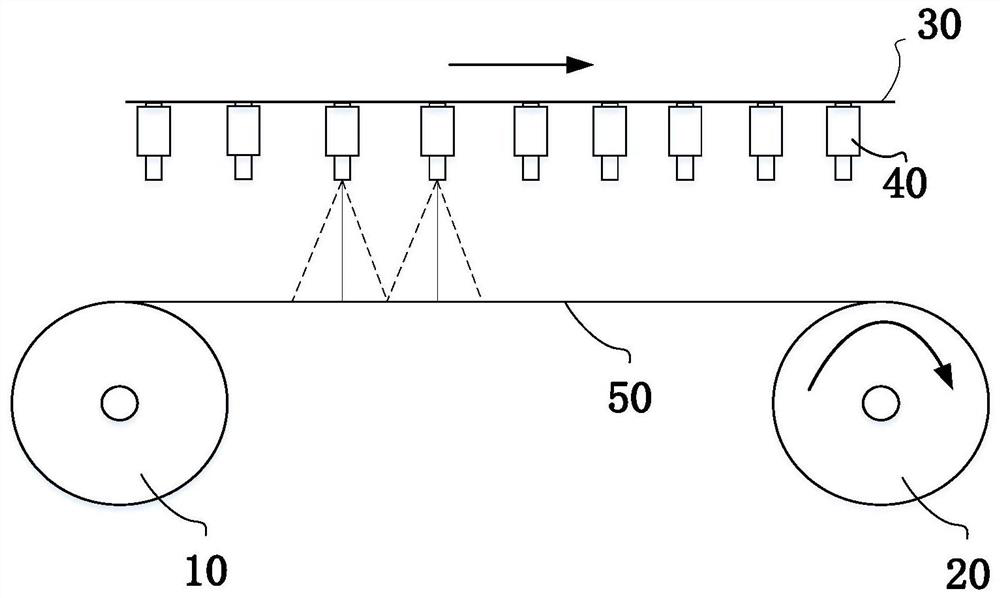

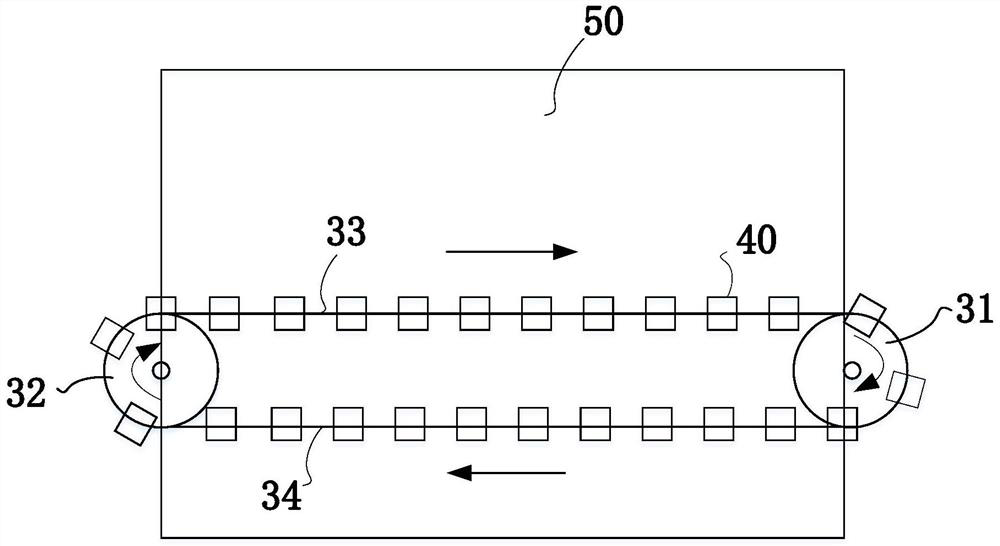

[0035]5G-based fabric defect detection system, such asFigure 2-4Shown, including:

[0036]The cloth winding device is used to wind the cloth and form the unfolded cloth to be tested 50; in one embodiment, such asfigure 2 As shown, the cloth winding equipment at least includes a driving winding wheel 20 driven by a driving device, and a driven winding wheel 10 for winding the cloth 50 to be inspected; initially, the cloth 50 to be inspected is wound on the driven winding wheel 10 Above, after the movement of the active winding wheel 20 starts, the cloth 50 to be inspected is gradually wound to the side of the active winding wheel 20 due to the winding effect, and the defects of the cloth are photographed during the process;

[0037]The endless circulating conveying line 30 is set directly above the cloth 50 to be inspected to evenly distribute a number of industrial camera groups 40; the cloth winding speed of the cloth winding equipment is consistent with the moving speed of the endless c...

Embodiment 2

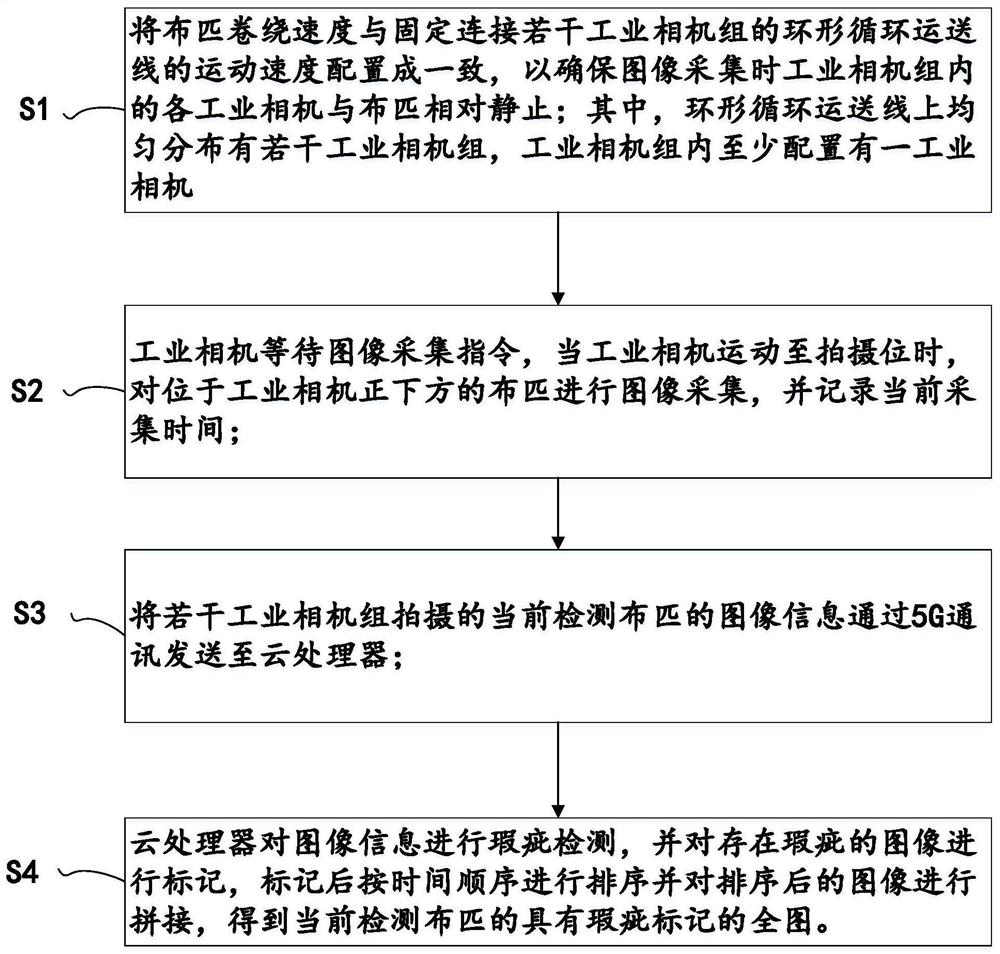

[0045]5G-based fabric defect detection methods, such asfigure 1 As shown, including the following steps:

[0046]S1. Configure the cloth winding speed to be consistent with the movement speed of the endless circulating conveying line that is fixedly connected to several industrial camera groups to ensure that the industrial cameras and the cloth in the industrial camera group are relatively stationary during image collection; among them, the endless circulating conveying line There are a number of industrial camera groups evenly distributed in the industrial camera group, and at least one industrial camera is configured in the industrial camera group; in the prior art, a stationary industrial camera is used to shoot the cloth, which greatly limits the winding speed of the cloth. The speed is too fast, and the industrial camera is not enough Shooting a complete cloth is prone to gaps; the speed is too low, which reduces the overall detection efficiency; at the same time, due to relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com