Power plant circulating water pump predictive state evaluation method and system

A technology of circulating water pump and state assessment, which is applied in forecasting, information technology support systems, instruments, etc., can solve the problems of less predictive maintenance of equipment, high cost-effectiveness ratio, unable to meet the preventive maintenance of nuclear power plants, etc., to improve early warning and judgment. Accuracy, reduce equipment damage, achieve the effect of preventive maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention is described in further detail:

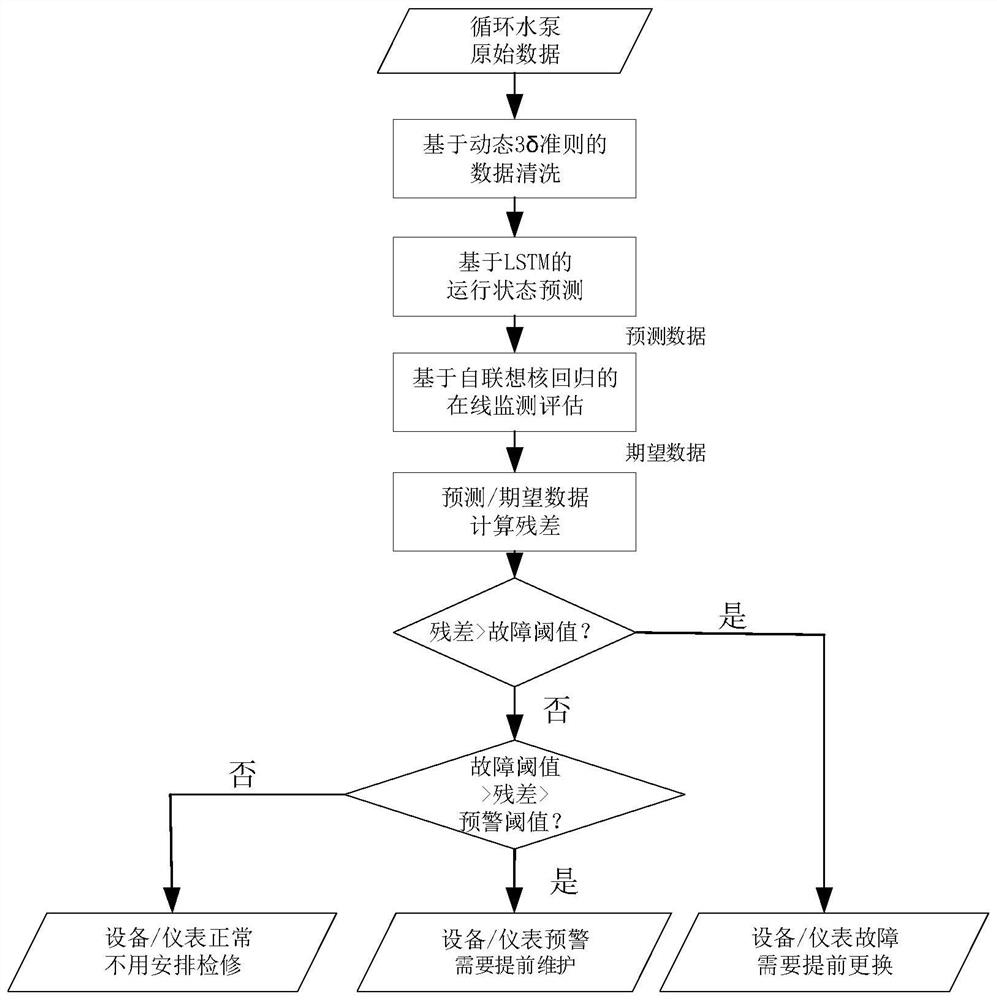

[0045] The volume and weight of the circulating water pump unit are huge (more than 20 meters high, about 8 meters in diameter, and about 100 tons in weight). The core equipment and instruments of the unit are various, and the related systems include more than 20 items such as motors, gearboxes, impellers and lubricating oil systems, and more than 80 instruments. The maintenance period for overhaul and disintegration is several months, and the maintenance of all unknown disintegrations takes a long time, and a lot of manpower and material resources are invested, and the cost is extremely high. This post-event maintenance method costs a lot of manpower and material resources. Through the present invention, the operation data of the circulating water pump in the future period can be predicted, and the data can be regressed to estimate the operation state of the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com