Fertilizer spraying device for rice planting

A spraying device and fertilizer technology, which is applied in the direction of spraying devices, fertilization devices, fertilizer distributors, etc., can solve the problems of self-regulated use, application of single granular fertilizer or liquid fertilizer, and high input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

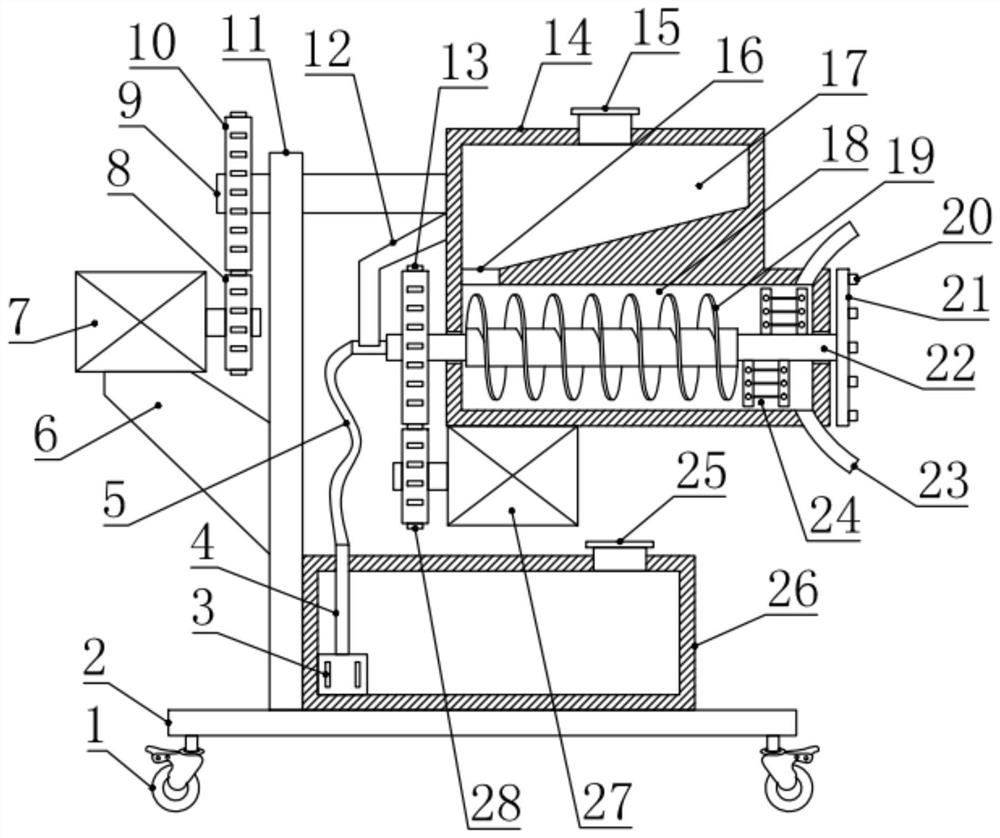

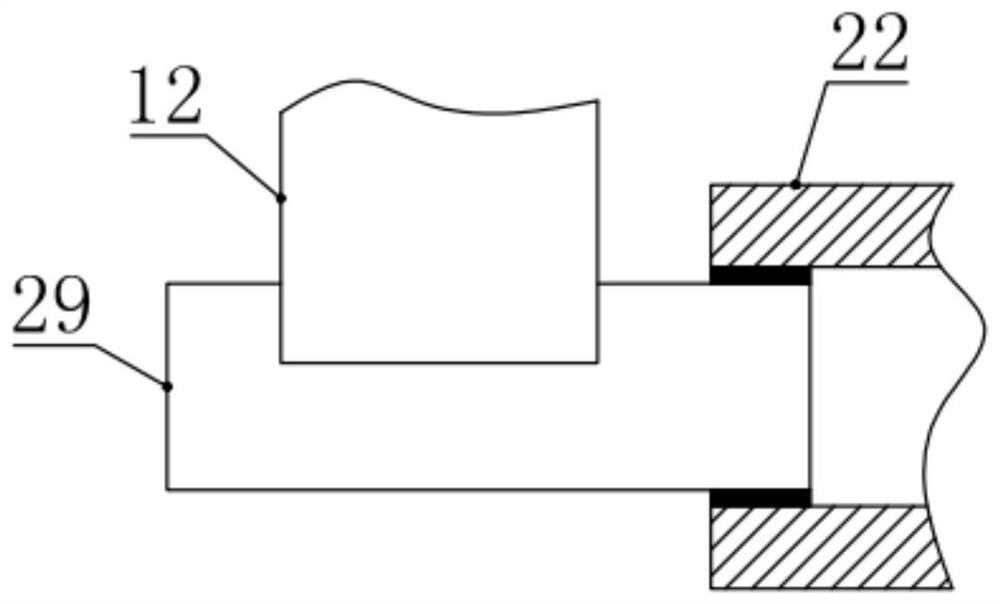

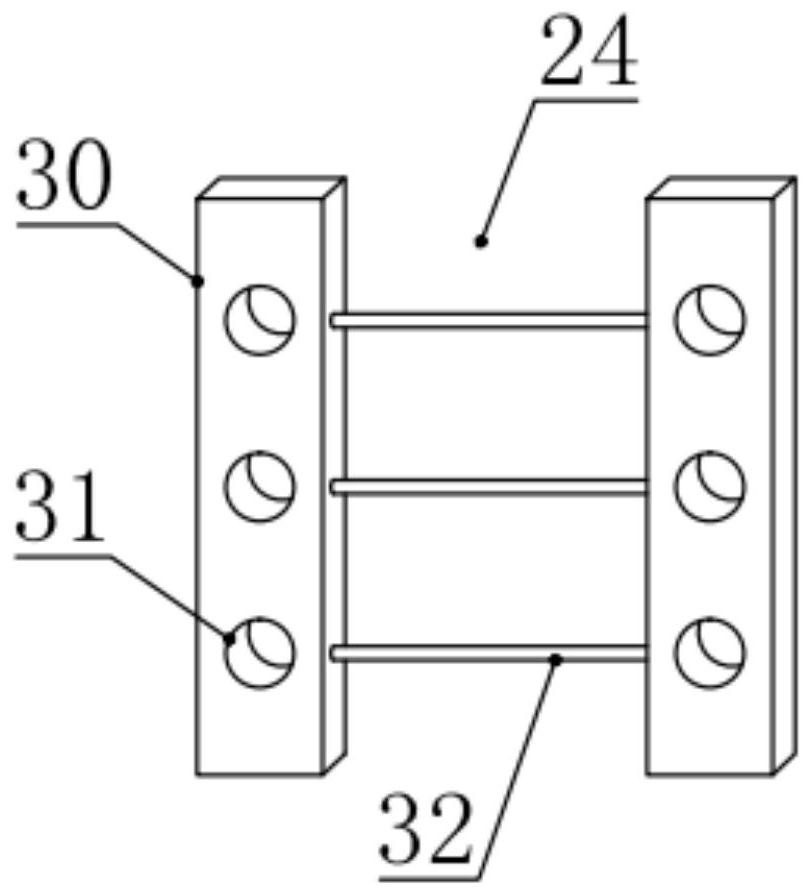

[0027] see figure 1 and 2 , in an embodiment of the present invention, a fertilizer spraying device for rice planting includes a base plate base 2 and a frame 11, the frame 11 is fixed on the base plate base 2, and a supporting horizontal shaft 9 is rotatably installed on the frame 11. The frame 11 is also equipped with a first driving mechanism for driving the supporting horizontal shaft 9 to reciprocate. One end of the supporting horizontal shaft 9 is fixed with a spraying body 14, and the inner upper and lower parts of the spraying body 14 are respectively provided with granular fertilizer storage chambers. 17 and the feeding and breaking up chamber 18, and the granular fertilizer storage chamber 17 communicates with the left end of the feeding and breaking up chamber 18 through the fertilizer drop port 16, and a rotating pipe 22 is installed in the described feeding and breaking up chamber 18, and the feeding Screw blade 19 is installed on the rotating tube 22 in the cavi...

Embodiment 2

[0030] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0031] In this embodiment, a plurality of universal wheels 1 with brakes are installed on the bottom of the base plate base 2, and the universal wheels 1 with brakes facilitate the flexible movement of the device.

[0032] Described first drive mechanism comprises motor fixed frame 6, first motor 7, first driving gear 8 and first driven gear 10, and described first driven gear 10 is fixed on the supporting cross shaft 9, and first motor 7 is connected and fixed with the frame 11 through the motor fixing frame 6, the first driving gear 8 is installed and fixed on the output shaft of the first motor 7, and the first driving gear 8 and the first driven gear 10 are engaged and connected, Through the operation of the first motor 7, the supporting horizontal shaft 9 can be driven to rotate back and forth.

[0033]The bottom of the granular fertilizer storage chamber 17 is inclined upwards at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com