Bending groove forming device for furniture decoration boards

A technology for bending grooves and boards, applied in the direction of slotting machines, manufacturing tools, mortising machines, etc., can solve the problems of difficult to control the depth of each cutting, different slot spacing, and inconvenient movement of electric saws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

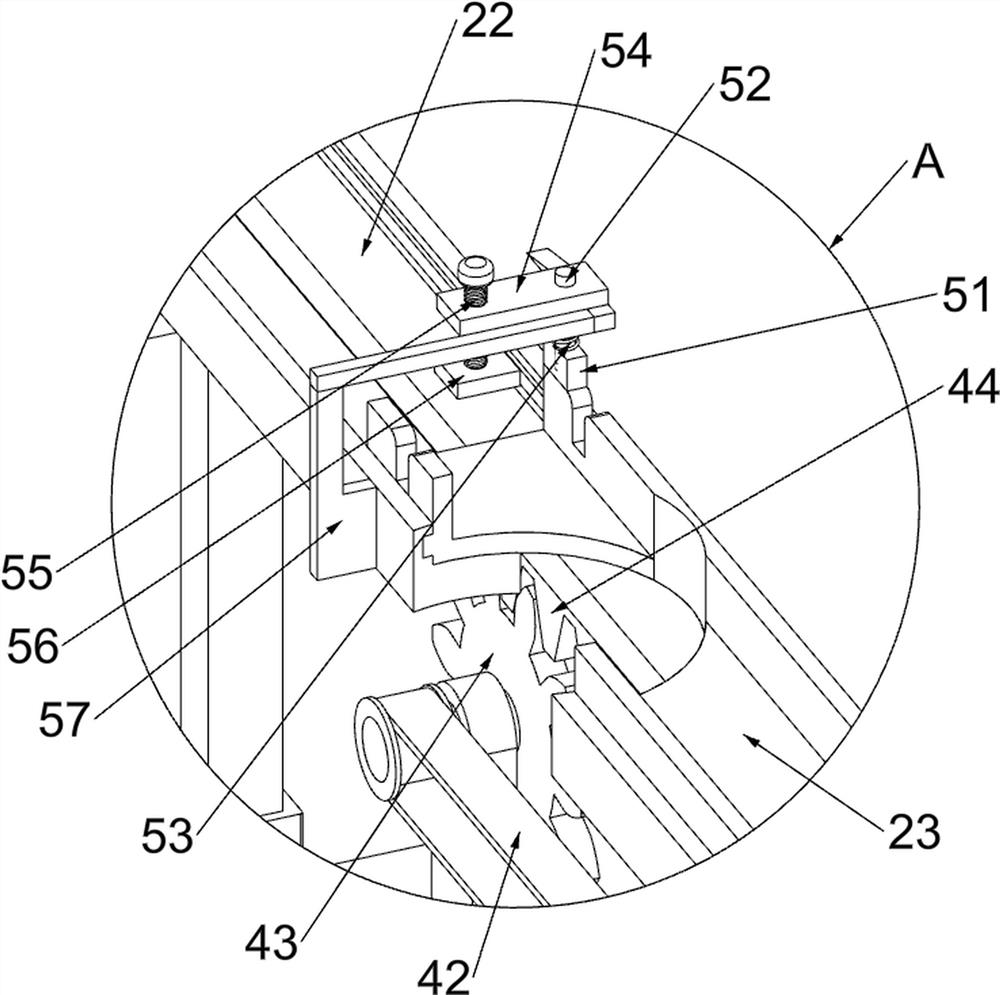

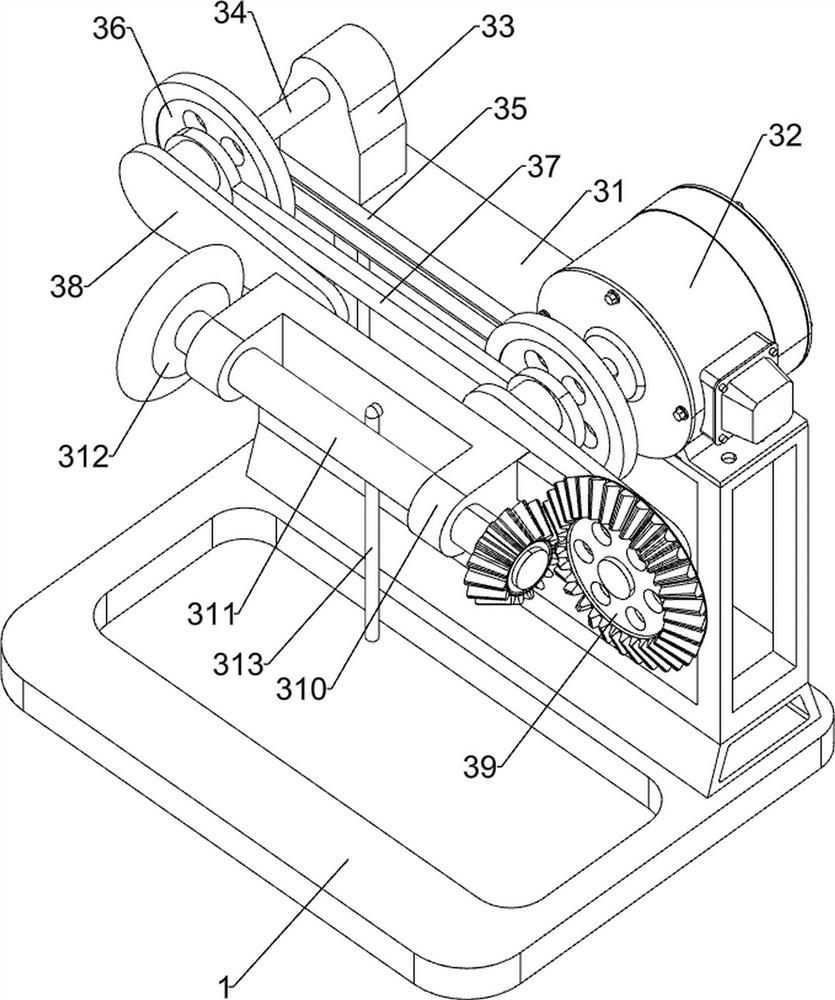

[0055]A device for opening curved grooves on wooden boards for furniture decoration, such asfigure 1 As shown, a mounting frame 1, a placing mechanism 2 and a cutting mechanism 3 are included. A placing mechanism 2 is connected between the left and right sides of the top front side of the mounting frame 1, and a cutting mechanism 3 is provided on the top rear side of the mounting frame 1.

[0056]When it is necessary to slot the wooden board for furniture decoration, the staff can place the wooden board in the placement mechanism 2, and the internal parts of the placement mechanism 2 clamp the board, and then start the cutting mechanism 3 to work, and at the same time manually push the inside of the placement mechanism 2 manually. The piece moves to drive the wood board to move. Under the action of the cutting mechanism 3, the wood board is slotted. After the wood board is slotted, the cutting mechanism 3 stops working, and the staff can collect and place the slotted wood board.

Embodiment 2

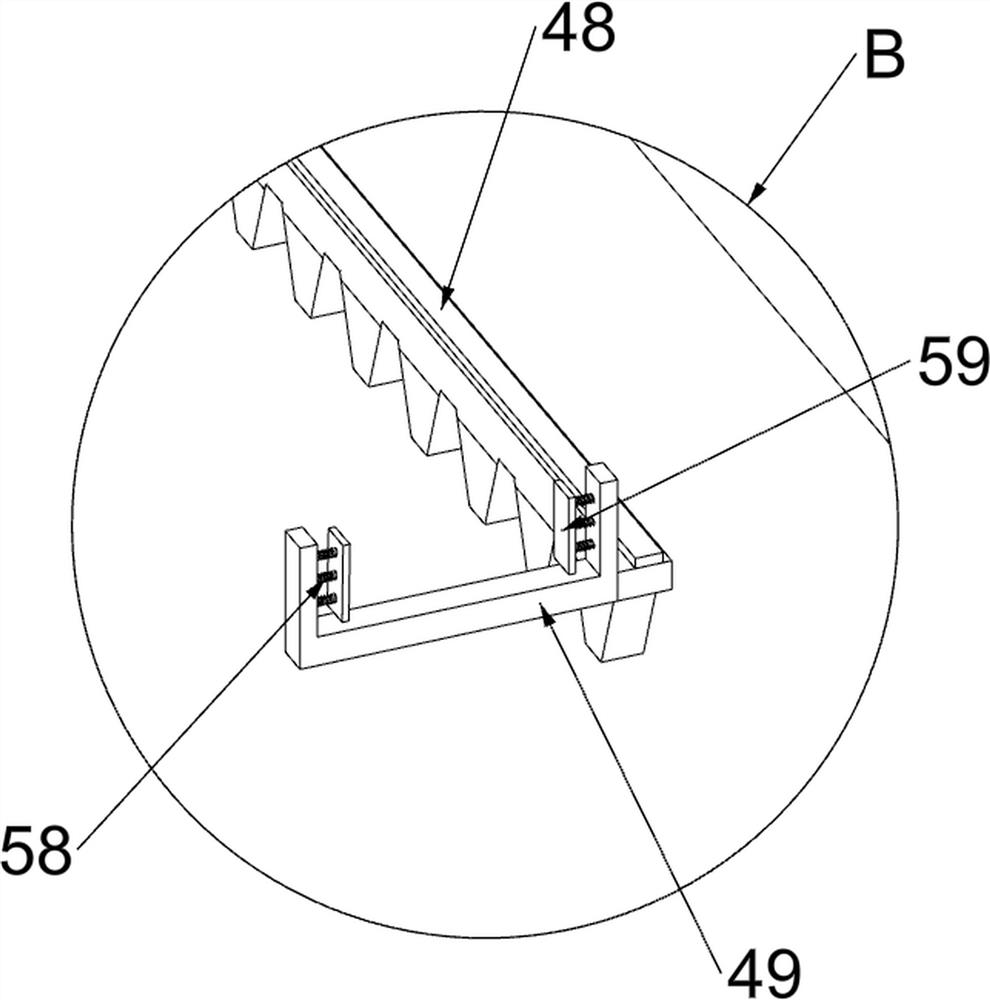

[0058]On the basis of Example 1, such asfigure 2 As shown, the placement mechanism 2 includes a first mounting post 21, a sliding rail 22, a placement plate 23, an extrusion rod 24, a first spring 25, an extrusion block 26, and a sliding sleeve 27. The top left and right sides of the mounting frame 1 are provided There is a first mounting column 21, the top of the first mounting column 21 is connected to the front and rear sides of the slide rail 22, between the upper part of the slide rail 22 is slidably provided with a placement plate 23 on the right side. A first spring 25 is connected between the pressing rod 24, the pressing rod 24 and the front side of the placement plate 23. The front side slide rail 22 is provided with a pressing block 26 on the left and middle of the front side, and the rear right side of the placement plate 23 With sliding sleeve 27.

[0059]The worker can place the wooden board in the placing board 23. At this time, the wooden board pushes the pressing rod 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap