Grinding and polishing equipment for stainless steel product production and processing

A stainless steel and product technology, applied in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve the problem of high local temperature, achieve the effect of ensuring the grinding effect and improving the production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

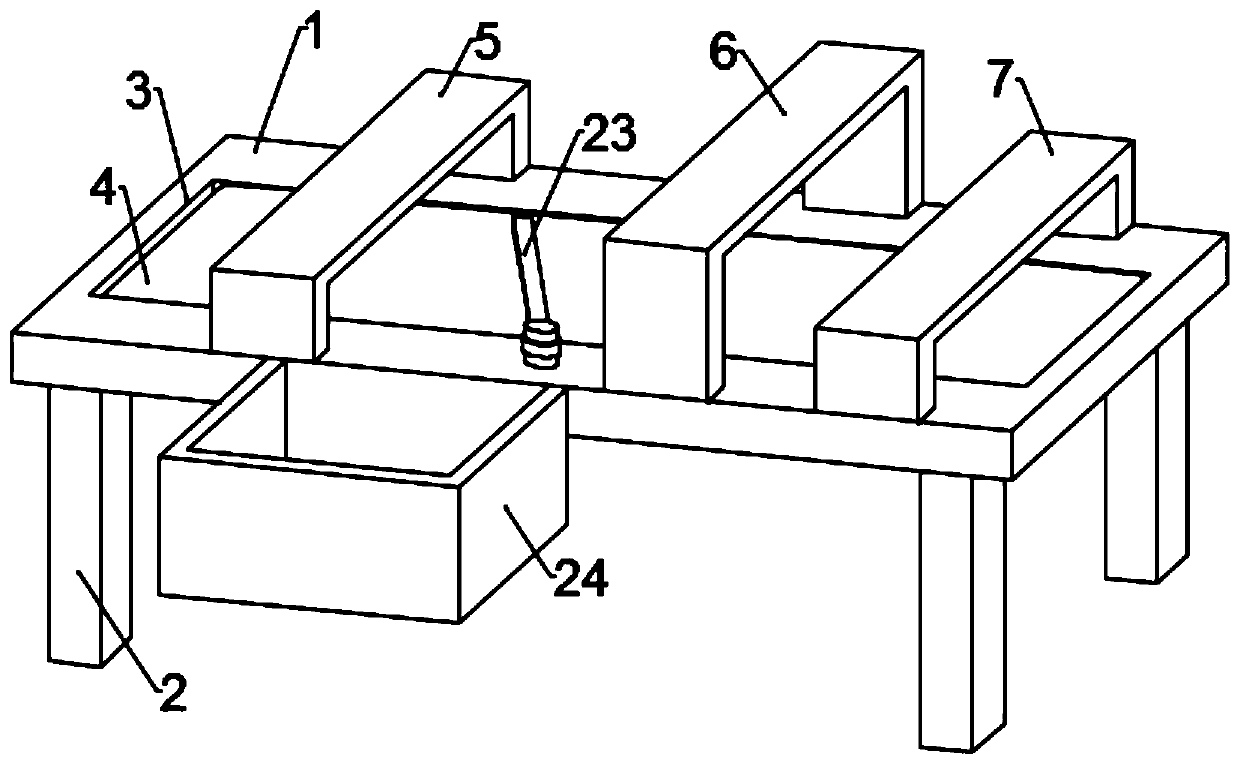

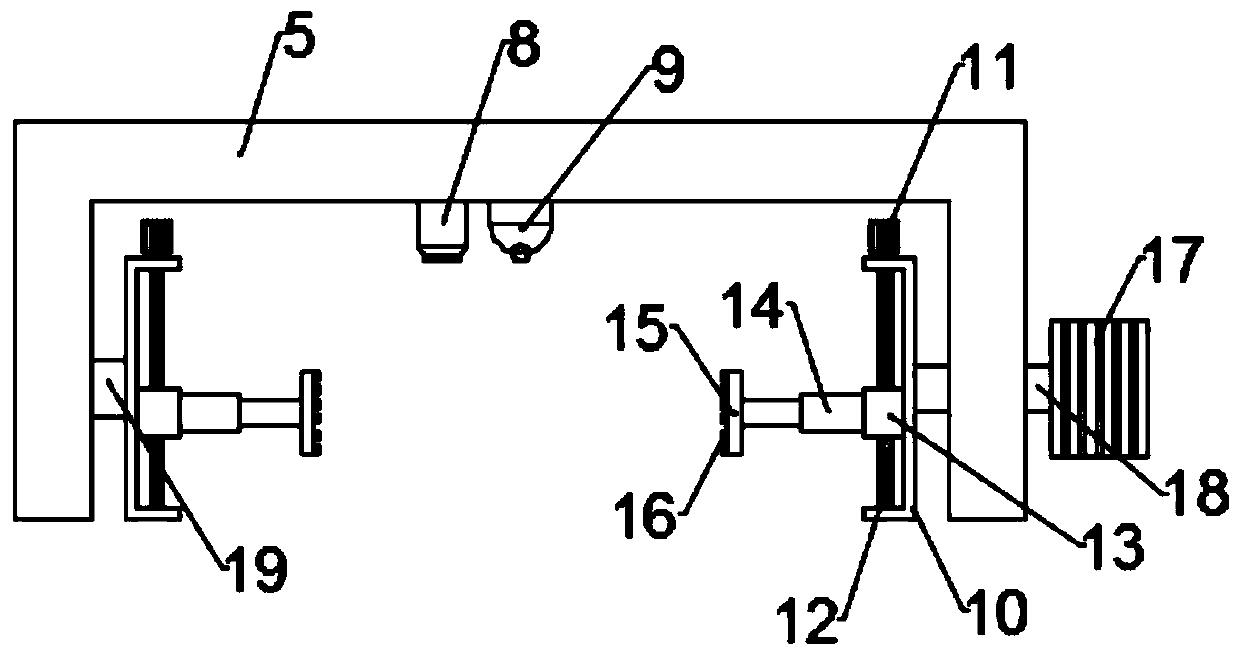

[0033] Such as Figure 1~5 As shown, the embodiment of the present invention provides a kind of grinding and polishing equipment for the production and processing of stainless steel products. The grinding and polishing equipment includes a processing table 1. The bottom of the processing table 1 is fixed with support legs 2. There is an empty slot 3, a conveyor belt 4 is installed inside the empty slot 3, and a grinding mounting frame 6 and a polishing mounting frame 7 are successively arranged above the conveyor belt 4; a movable grinding mechanism is installed on the top of the grinding mounting frame 6 , the inner wall of the grinding mounting frame 6 is equipped with a multi-angle air-cooling heat dissipation mechanism; the top of the polishing mounting frame 7 is equipped with a rotating polishing mechanism; the front side of the grinding mounting frame 6 is provided with a screening and dialing mechanism.

[0034] The grinding and polishing equipment for the production a...

Embodiment 2

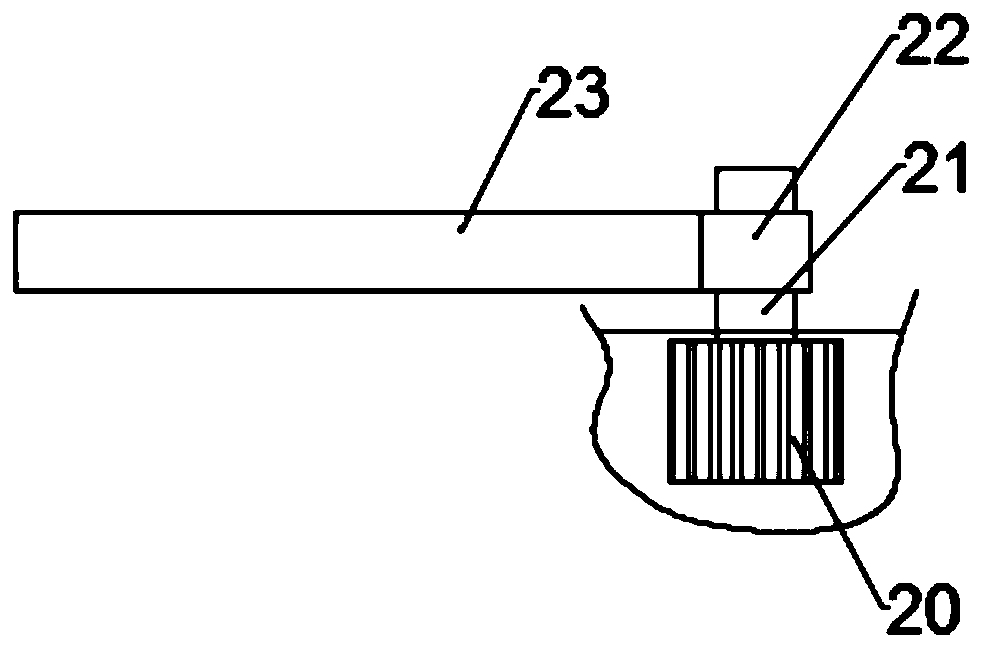

[0043] Such as Figure 1~3 As shown, in yet another embodiment provided by the present invention, the screening and dialing mechanism includes an omnidirectional identification assembly and a dialing assembly; the omnidirectional identification assembly includes a screening mounting frame 5, and the screening mounting frame 5 is installed on the Above the conveyor belt 4, the material shifting assembly is located between the screening mounting frame 5 and the grinding mounting frame 6, and the side wall of the processing table 1 is provided with a collection box 24, and the collection box 24 is connected to the material pushing assembly Corresponding.

[0044] When the conveyor belt 4 drives the stainless steel products to move, they first pass through the screening mounting frame 5 and are screened and determined by the all-round identification assembly.

[0045] Further, the omni-directional identification component includes an image acquisition device 9 installed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com