Electric fine adjustment system for screen frame of printing machine and printing machine

A printing machine and screen frame technology, which is applied to the electric fine-tuning system of the screen frame of the printing machine and the field of printing machines, can solve the problems of heavy workload, lost steps of the motor, and affecting production efficiency, so as to achieve precise alignment of pattern positions, improve production efficiency, Retrieve convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

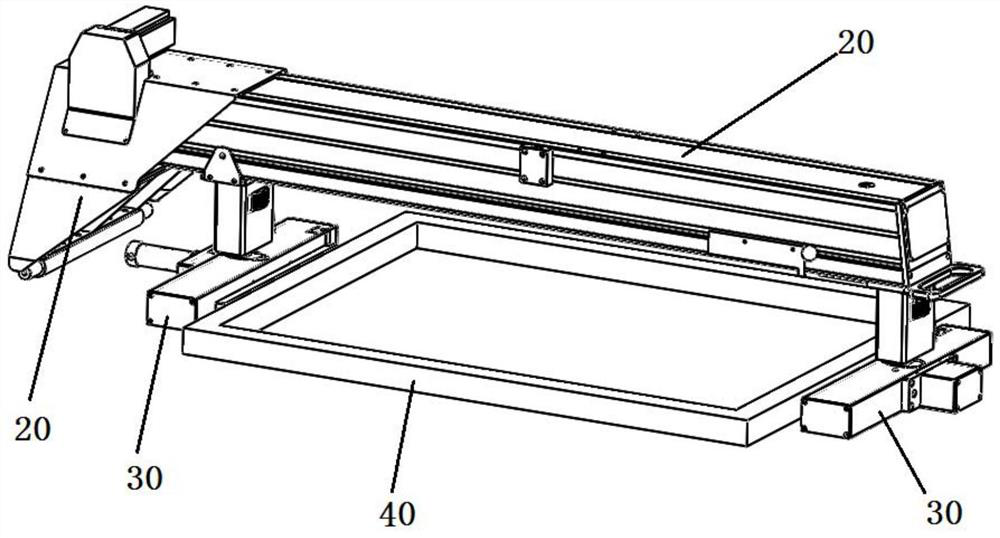

[0030] Please refer to figure 1 , figure 1 It is a schematic structural diagram of the electric fine-tuning system for the screen frame of the printing machine described in Embodiment 1 of the present invention. As shown in the figure, Embodiment 1 of the present invention provides an electric fine-tuning system for the screen frame of the printing machine, including a print head beam base 10, a print head beam 20. At least two fine adjustment devices 30 and a control device (not shown in the figure); one end of the print head beam 20 is fixed to the print head beam base 10; two fine adjustment devices 30 are symmetrically arranged at both ends of the print head beam 20.

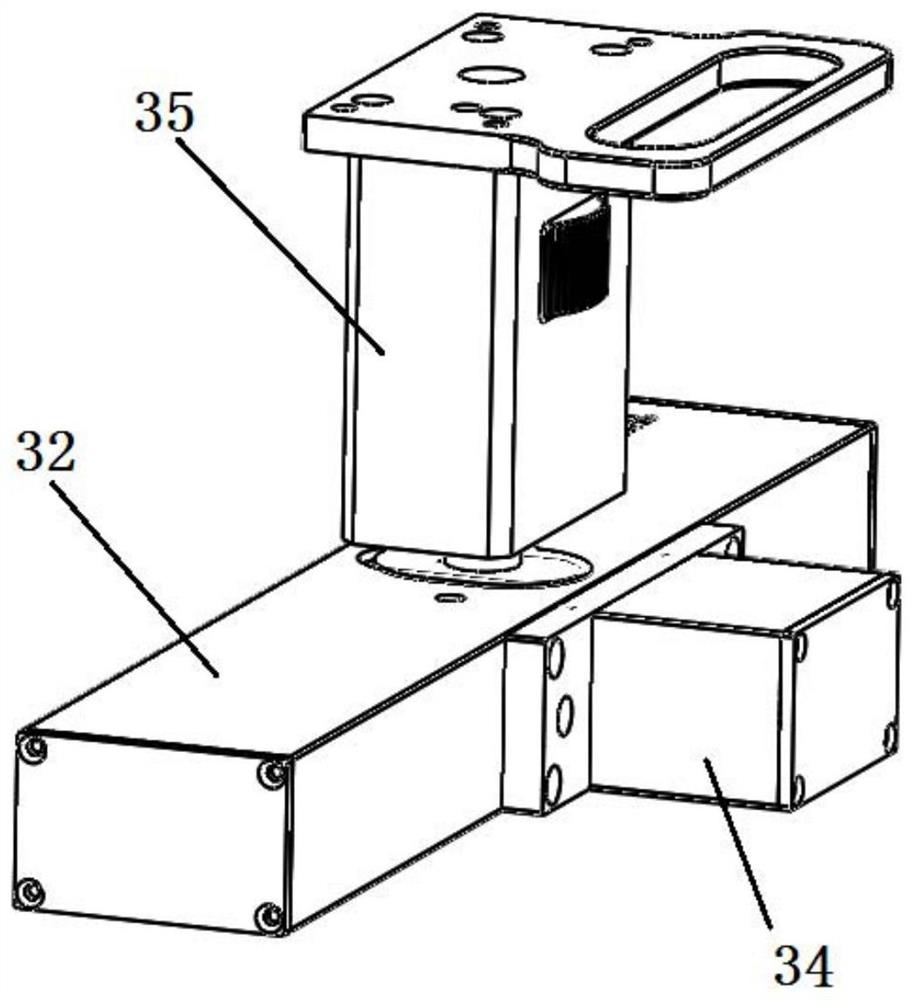

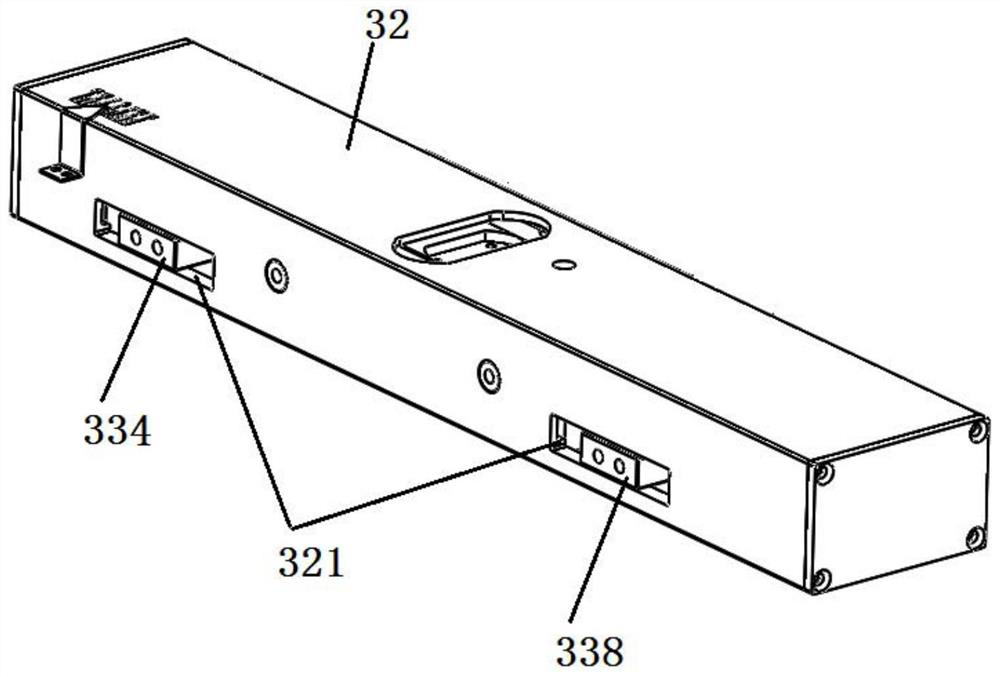

[0031] Please refer to figure 2 , figure 2 It is a schematic diagram of the overall structure of the fine-tuning device described in Embodiment 1 of the present invention. Each fine-tuning device 30 includes a screen frame beam 31 , a fine-tuning frame 32 , an X-axis moving group 33 , a Y-axis moving gr...

Embodiment 2

[0050] Embodiment 2 of the present invention also provides a printing machine, which includes the above electric fine-tuning system for the screen frame of the printing machine. The printing machine has the characteristics of precise electric fine-tuning of the screen frame and real-time feedback of the fine-tuning position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com