Bottom cover type pipeline intake and exhaust valve

A technology of intake and exhaust valves and pipelines, which is applied in the field of pipeline valves, can solve problems such as poor intake and exhaust, flat suction and rupture of pipelines, and achieve reliability and practicability, flexible floating balls, and improved service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

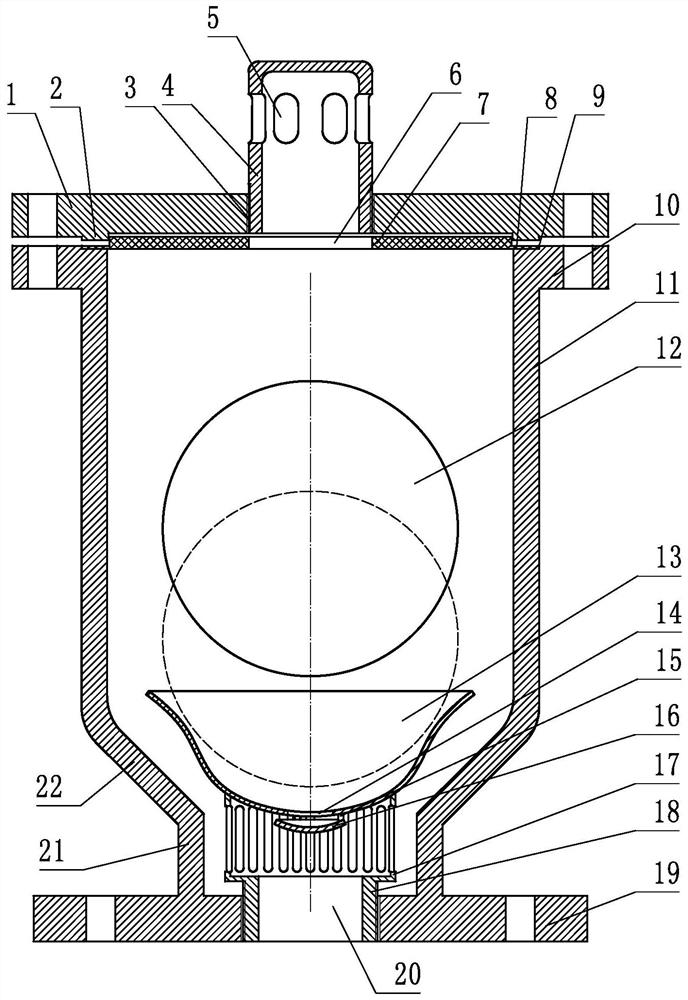

[0024] Embodiment 1: refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, including a valve body 11, an upper flange 10, a lower flange 19, a bonnet 1, a bonnet hole 3, a spool 4, a spool hole 5, a gasket 7, and a gasket The hole 6 and the float 12 are provided with an upper flange 10 at the upper end of the valve body 11, a constriction portion 22 is provided at the bottom end of the valve body 11, a neck portion 21 is provided at the bottom end of the constriction portion 22, and a neck portion 21 is provided at the bottom end of the neck portion 21. The bottom end of the valve body is provided with a lower flange 19, a floating ball 12 is provided in the valve body 11, and a gas distribution protective cover 13 with a diameter larger than the floating ball 12 is provided below the floating ball 12. The gas distribution protective cover in this embodiment 13 is a bowl-shaped body with an open upper part, or an inverted helmet shape,...

Embodiment 2

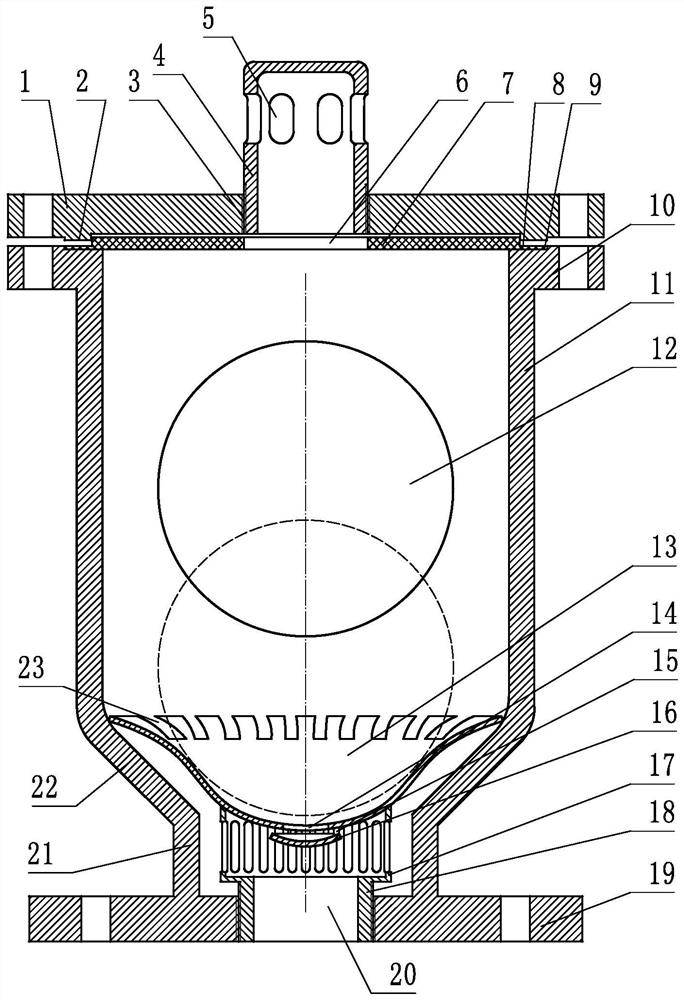

[0026] Embodiment 2: refer to figure 2 , is a schematic structural diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of Embodiment 2 is that in Embodiment 2, evenly distributed zigzag grooves are provided on the edge of the gas distribution protective cover 13 23. Groove 23 is formed by openings on the upper edge of the air protection cover 13, which can make the air intake and exhaust more fluent.

Embodiment 3

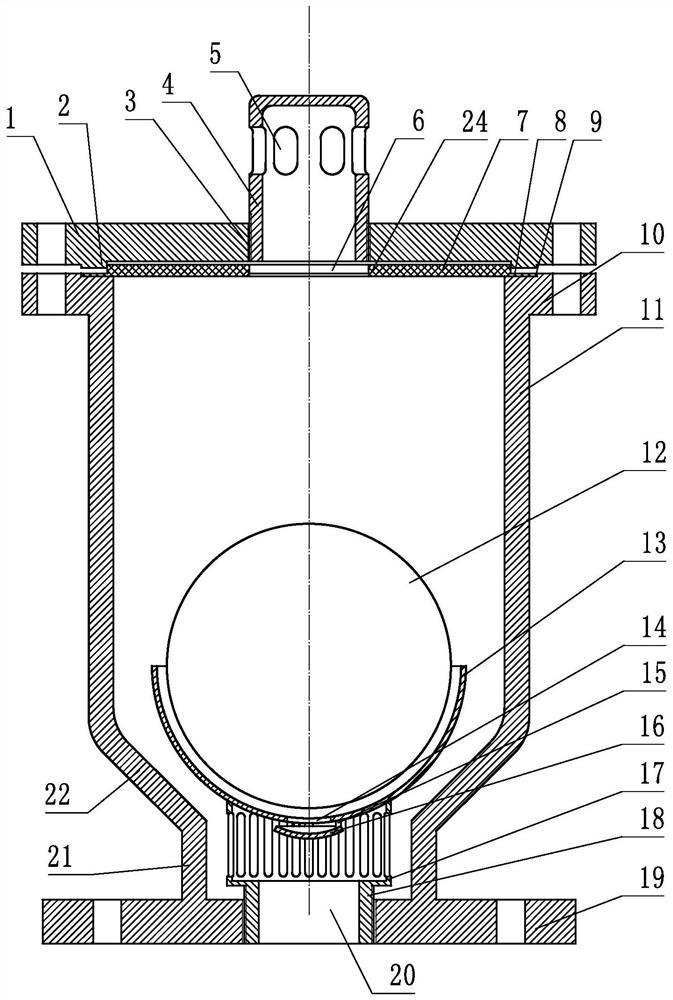

[0027] Embodiment 3: refer to image 3 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with the previous embodiments, the difference of Embodiment 3 is that the gas distribution protective cover 13 in Embodiment 3 is semicircular, and can also play the same role .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com