Glass fiber reinforced plastic blow-off pipeline construction method

A technology for sewage pipelines and construction methods, which is applied in the direction of pipeline connection layout, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. It can solve the problems of increasing the workload of employees, wasting manpower, and pipeline leakage, etc., and achieve work efficiency. , improve stability, and enhance workload effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

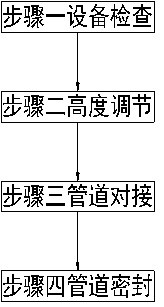

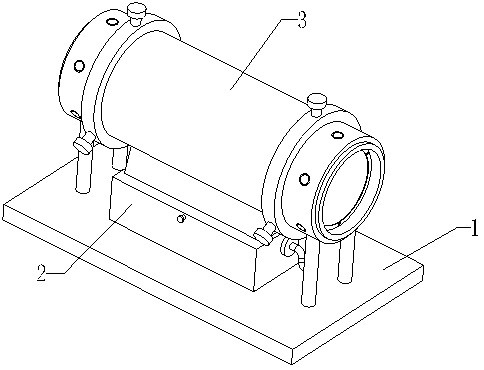

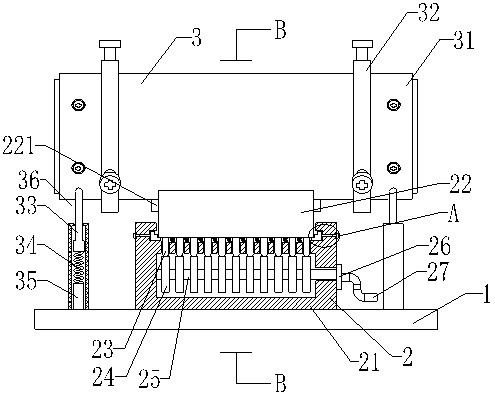

[0031] Such as Figure 1 to Figure 7 Shown, a kind of FRP sewage pipeline construction method mainly comprises the following steps:

[0032] Step 1: Equipment inspection: Check the operation of the equipment before using the FRP sewage pipe docking device to dock the FRP sewage pipe;

[0033] Step 2: height adjustment; manually turn the hand rocker 27 to drive the central rotating shaft 25 to rotate, thereby driving the adjustment cam 24 to rotate, thereby squeezing the connecting column 23 by rotating the cam, thereby achieving the purpose of adjusting the height of the arc support plate 22 , and then manually rotate the feed screw 316, thereby driving the support bar 20 to move to the lower end of the arc-shaped support plate 22 through the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com