Method and device for detecting backlash-free meshing of rigid gear of harmonic gear

A technology of harmonic gears and rigid wheels, which is applied in the field of backlash-free meshing detection of harmonic gears and rigid wheels, can solve the problems of low measurement efficiency, difficulty in aligning extreme position, low measurement accuracy, etc., and achieve convenient measurement operation , Reduce the impact of measurement accuracy and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

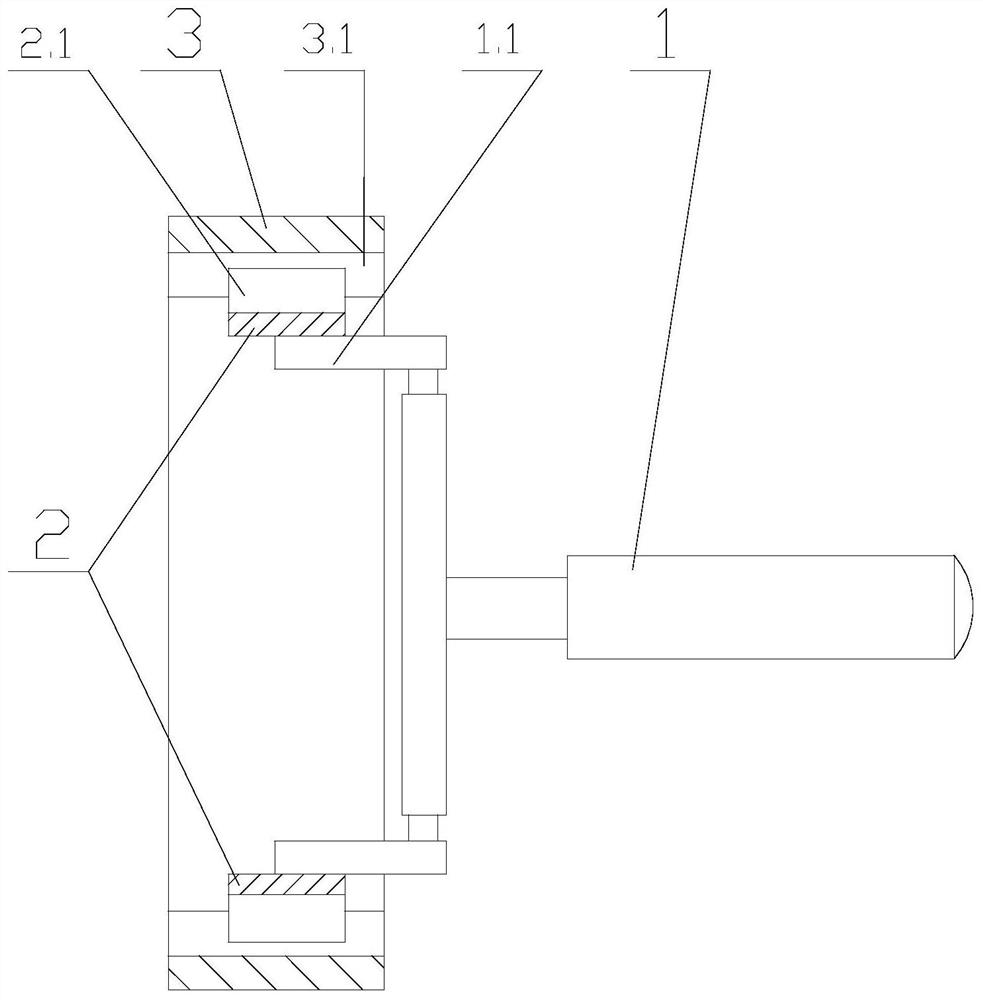

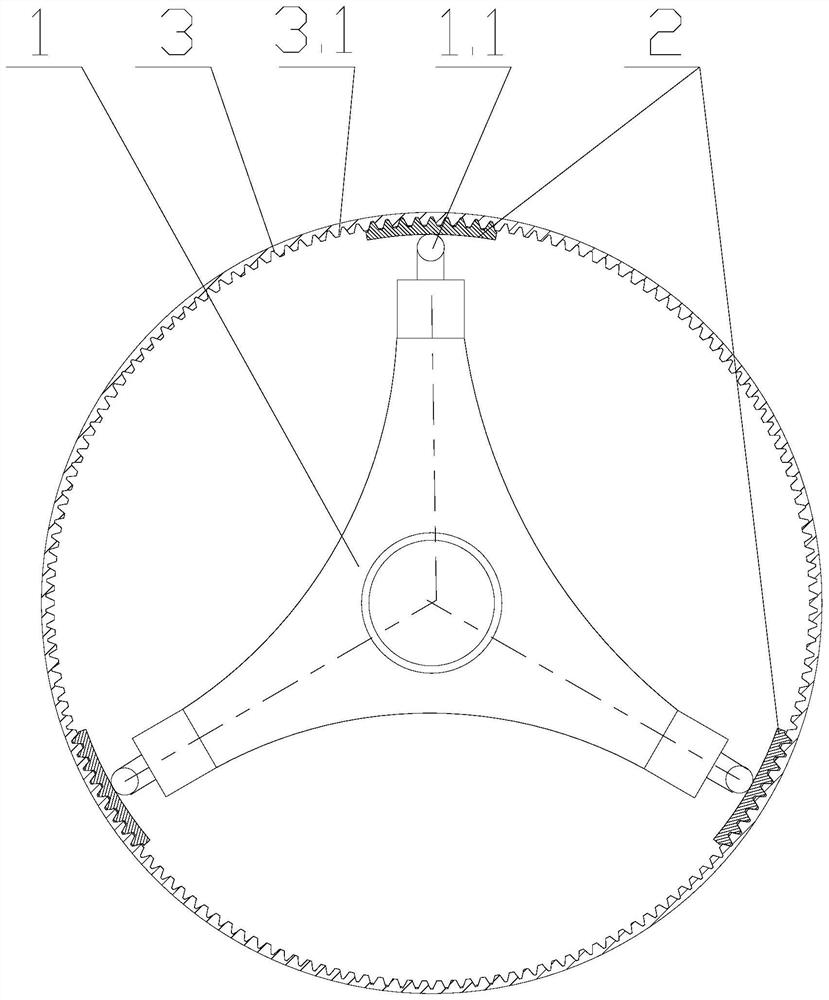

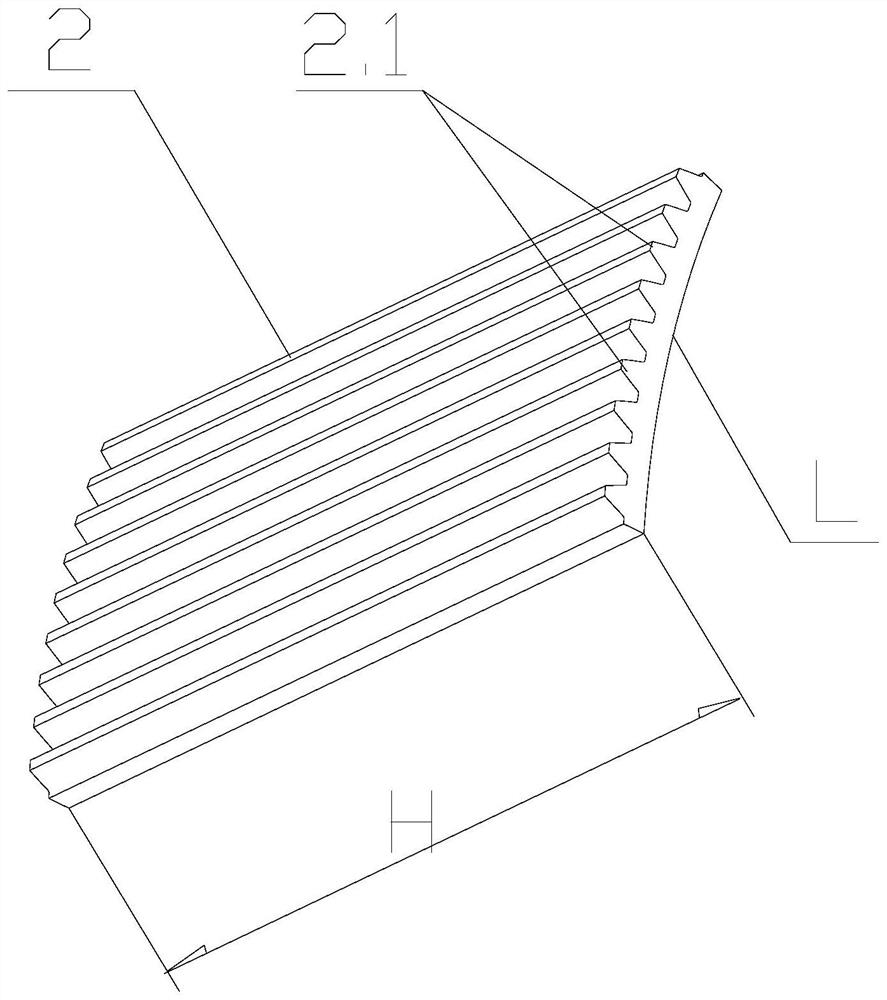

[0019] A method for detection of backlash-free meshing of harmonic gears and rigid wheels of the present invention, such as Figure 1~4 As shown, the method includes using a two-claw or three-claw inner diameter micrometer 1 to detect the internal teeth 3.1 of the rigid wheel 3 of the harmonic gear, that is, using a two-claw or three-claw inner diameter micrometer 1 to detect the inner teeth 3.1 of the rigid wheel 3 of the harmonic gear. When testing the internal teeth 3.1, a fan-shaped measuring block 2 is arranged on each measuring head 1.1 of the two-claw or three-claw inner diameter micrometer 1, and each measuring block is provided with an internal tooth 3.1 capable of connecting with the rigid wheel 3. The meshing gear teeth 2.1 make the gear teeth 2.1 of the measuring block 2 on each measuring head 1.1 of the two-jaw or three-jaw inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com