Anatomical measurement method for common thread root arc radius

A technology of arc radius and ordinary thread, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unable to measure the radius, unable to quantitatively measure the arc radius, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] A method for anatomically measuring the arc radius of a common thread bottom provided by the present invention comprises the following steps:

[0020] 1) Use wire cutting equipment to cut through the centerline of ordinary threaded parts and vertically to the thread longitudinally, and the section is made into a sample after rough grinding, fine grinding and polishing;

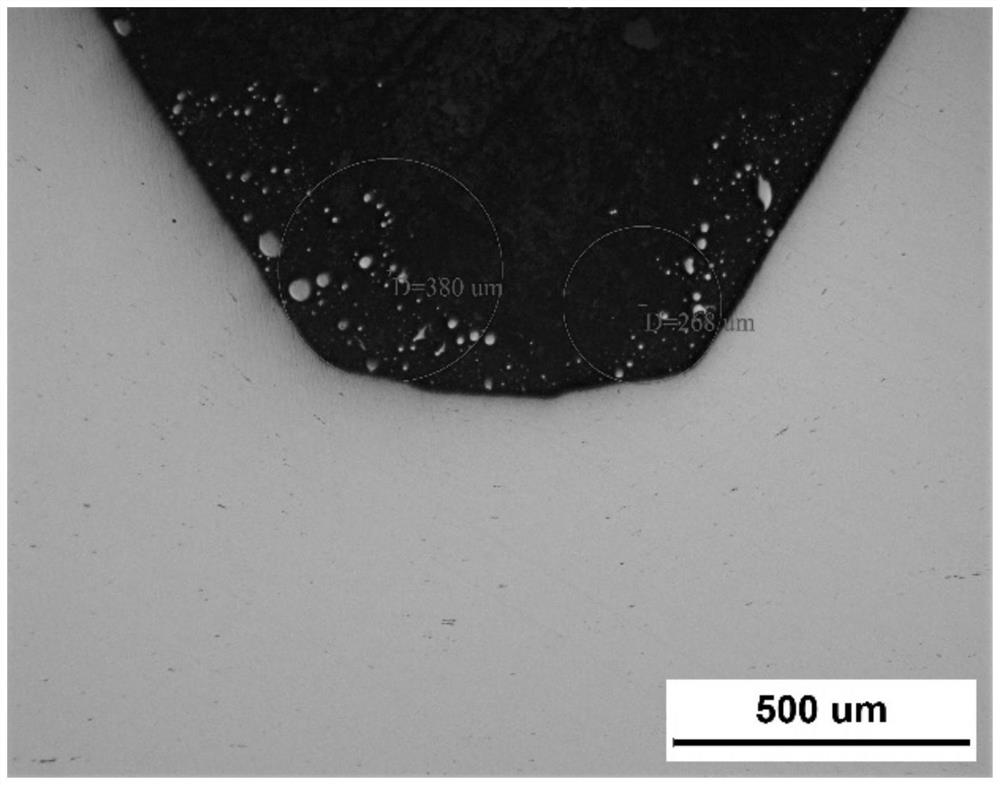

[0021] 2) Observing the prepared sample under a metallographic microscope with an appropriate magnification of the arc radius of the thread bottom and collecting images, choose 50 times, the shape of the arc radius of the tooth bottom is as follows figure 1 shown;

[0022] 3) Use the OLYCIA m3 metallographic image analysis system to analyze and measure the collected images, and use the "circle" tool in the "Advanced Image Measurement" to measure the arc radius of the thread bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com