Alarm root cause diagnosis method based on chemical process knowledge automation

A technology of chemical process and diagnosis method, which is applied in the direction of program control, comprehensive factory control, instrument, etc., can solve the problems of heavy workload in topology model establishment, over-reliance on manual decision-making, low accuracy of alarm root cause diagnosis, etc., and achieve good application Effectiveness, strong decision-making ability, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

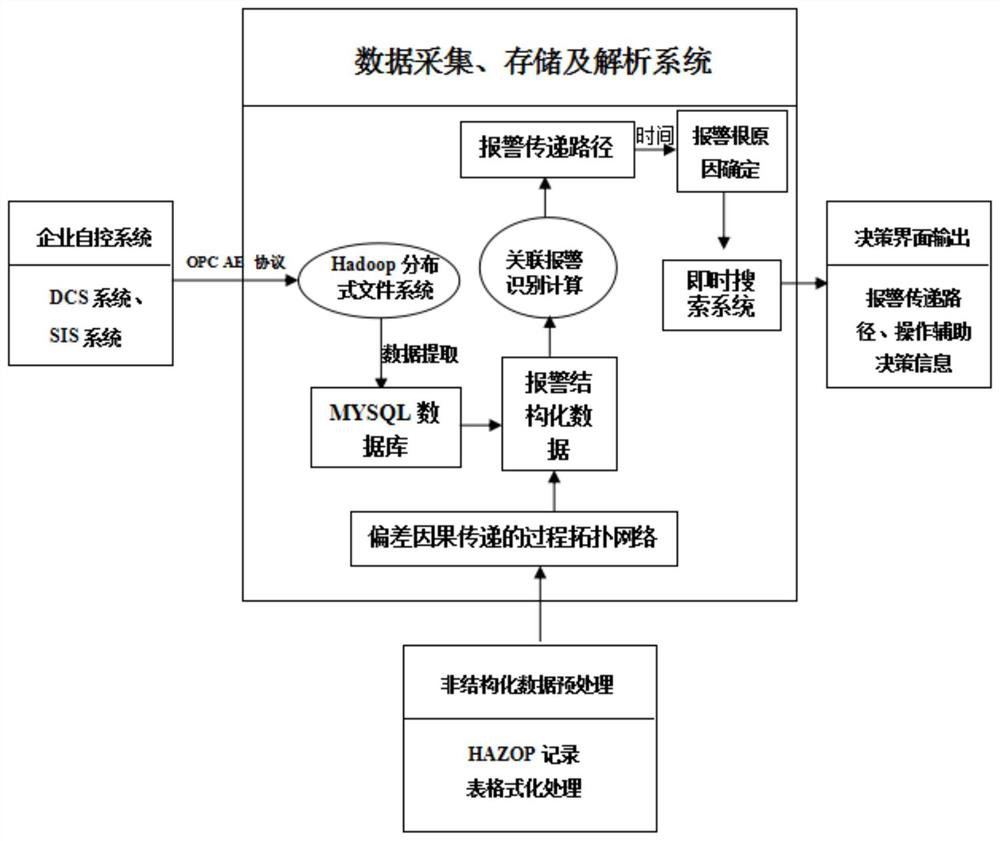

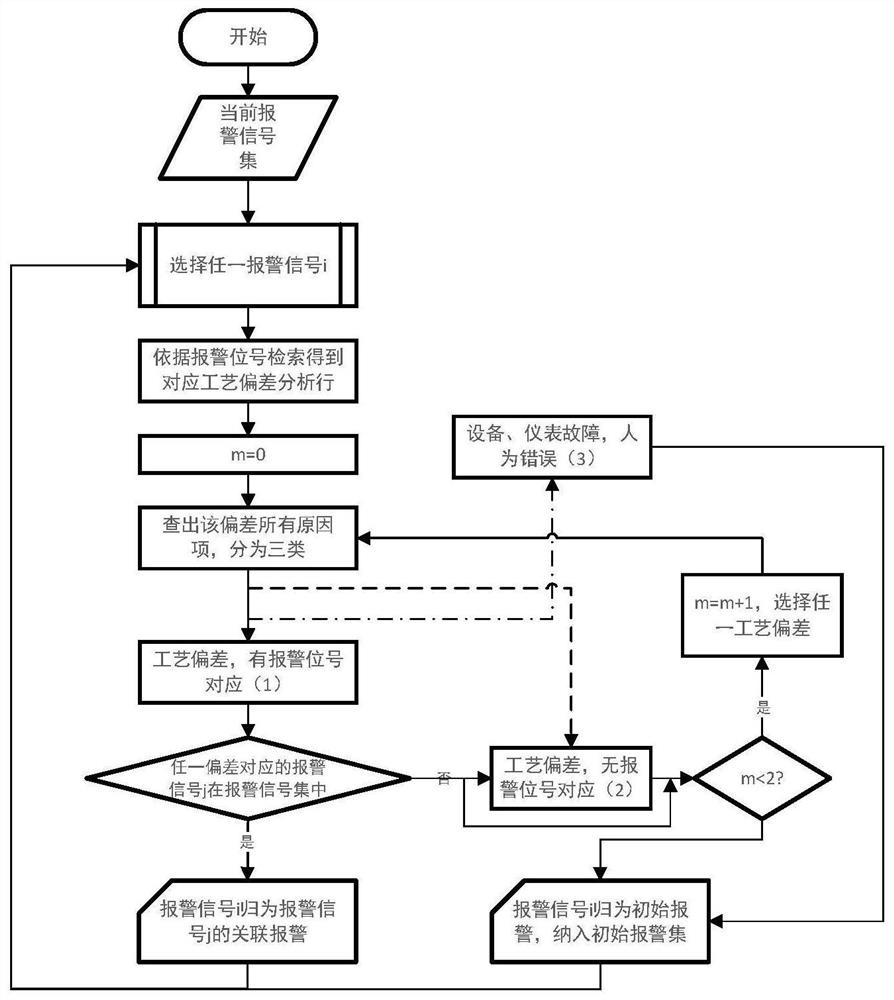

[0031] see Figure 1-3 , an automatic alarm root cause diagnosis method based on chemical process knowledge, including the following steps:

[0032] Step 1: Based on the analysis of deviation causal time series transfer, use chemical process knowledge to establish process topology, collect chemical process alarm data and time information; Step 2: judge the causal relationship between variables through path search, and automatically deduce the root cause of the alarm; Step 3: Automatically retrieve alarm root cause keywords through instant search engine, retrieve relevant operation information from database, and assist operators in decision-making.

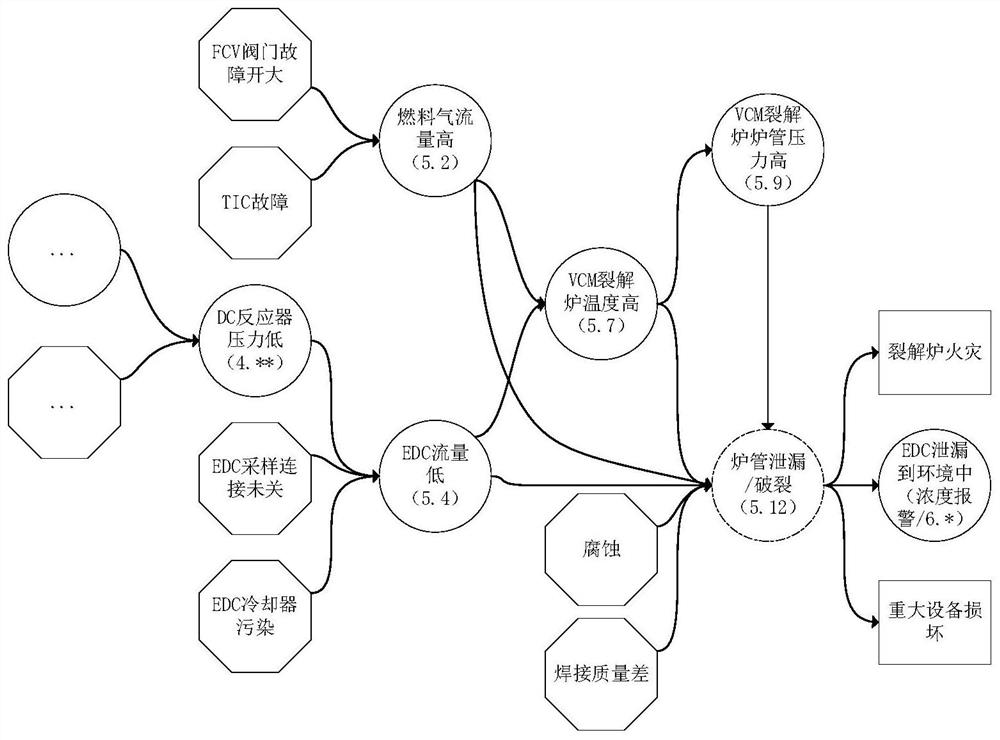

[0033] Establishment of deviation causal transfer process topology: using the improved HAZOP analysis method, optimize the HAZOP analysis table through initial cause-intermediate cause-deviation-intermediate consequence-final consequence, and establish a process that can be recognized by the computer through the causal correlation ...

Embodiment 2

[0043] see Figure 4 , the difference from the first embodiment is that the second embodiment has a decision output, the decision interface output: the root cause of the alarm is the initial node, and the causal transfer path is presented in the form of a symbolic directed graph. Among them, the alarm bit number with the highest alarm priority is highlighted.

[0044] exist Figure 4 In , the auxiliary decision-making information intelligently retrieved through the instant search system is displayed on the far left of the image. When the low EDC flow alarm, the high temperature alarm of the VCM cracking furnace and the high pressure alarm of the VCM cracking furnace tube occur at the same time, according to the established deviation causal transmission path, the associated alarm identification is automatically carried out. There are 3 reasons for the low EDC flow rate, and 2 reasons The initial reason is the low pressure of the EDC reactor and the other is the intermediate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com