An automatic detection method for broken springs of railway freight car bolster springs

A technology for automatic detection of railway wagons, applied in measuring devices, optical testing for flaws/defects, image enhancement, etc., can solve problems such as low detection efficiency and easy missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

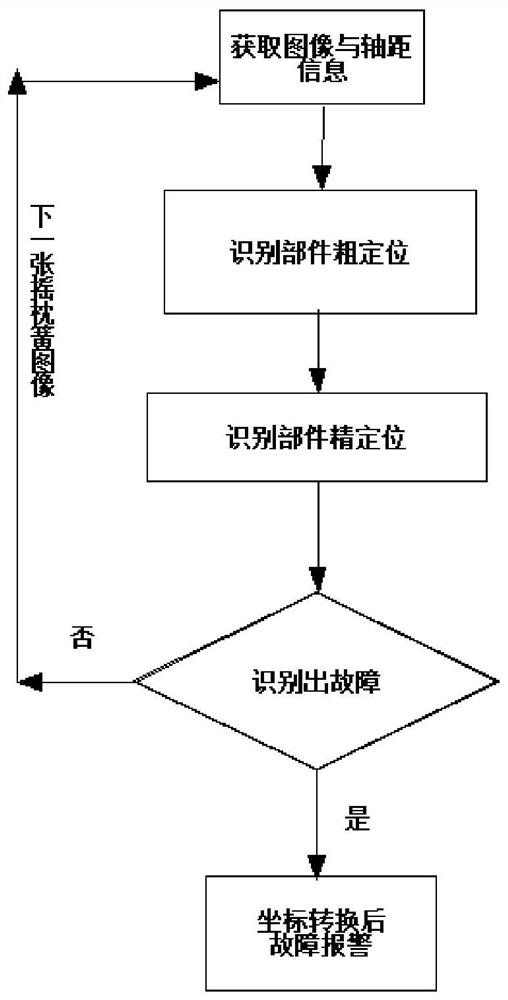

[0021] Specific implementation mode one: the specific process of a kind of automatic detection method for the broken fault of railway freight car bolster spring in this implementation mode is as follows:

[0022] Step 1. Build high-definition imaging equipment around the track to obtain high-definition images, and roughly locate the bolster spring components to obtain large images of bolster springs;

[0023] The high-definition imaging device includes a camera acquisition unit, a magnetic steel unit, an image acquisition industrial computer unit, a control industrial computer unit, and an image recognition unit;

[0024] The camera acquisition unit includes a camera and a compensation module;

[0025] The magnetic steel unit signal includes a near magnetic steel signal and a far magnetic steel signal;

[0026] The near-end magnetic steel and remote magnetic steel signals are transmitted to the control industrial computer unit, and the control industrial computer unit calcula...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in the step 2, the large image of the bolster spring is subjected to component recognition and fine positioning to obtain the sub-image including the head coil spring and adjacent components and the sub-image of the bolster spring , the specific process is:

[0035] Step 21. Obtain the outline of the large image of the bolster spring through Canny detection. The specific process is as follows:

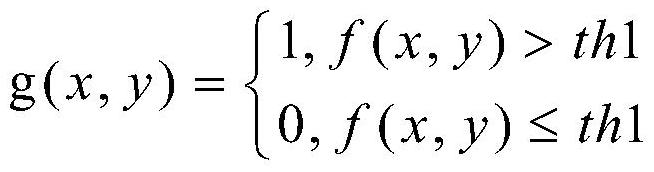

[0036] First, Gaussian smoothing filtering is performed on the large image of the bolster spring, and then the gradient of the filtered image in the x direction is calculated as Gx by using the Sobel operator, and the gradient of the filtered image in the y direction is calculated as Gy, and the L2 norm is obtained by using the gradients in the x and y directions Overall Gradient G. If the gradient image is a non-maximum value, its gradient is set to 0 to obtain a new gradient. Combined with the imag...

specific Embodiment approach 3

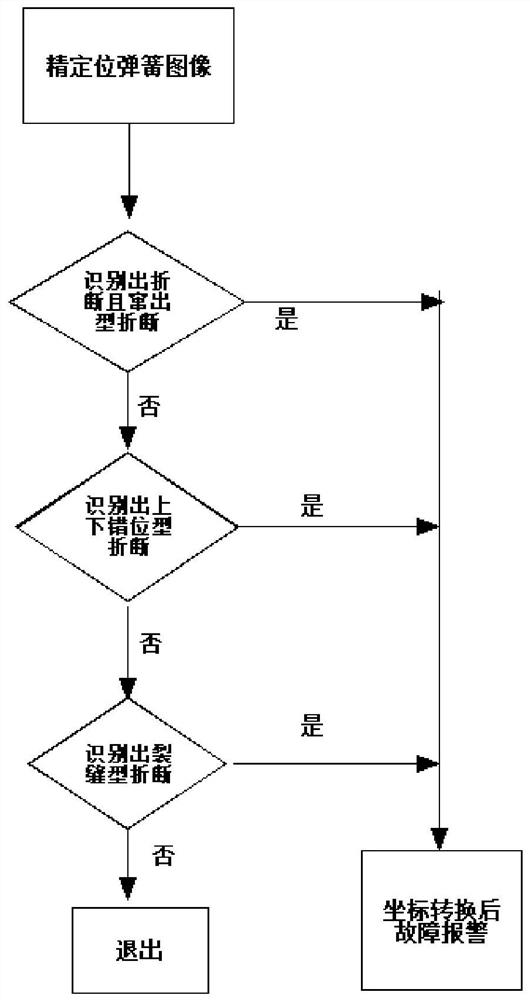

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: in the step 3, according to the image obtained in step 2, the fault identification of the bolster spring is carried out, and the specific process is as follows:

[0050] Step 31. By comparing with the fault-free image of the template to detect breakage and bursting type breakage:

[0051] Detect whether there is a broken and bursting fault pattern on the sub-image containing the head coil spring, and if it exists, it will directly alarm;

[0052] The current head coil spring sub-image and the non-faulty template image detect feature points through the surf operator, perform initial image matching based on the feature points, use the RANSAC algorithm to eliminate misplaced matching points, and calculate the image variable matrix based on the remaining matching points. After the current image is transformed according to the transformation matrix, it is compared with the fault-free image of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com