Processing method of cast polar plate in lead-acid storage battery

A lead-acid battery and processing method technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of high labor consumption, hazardous waste pollution, battery short circuit, etc., and achieve the effects of reducing waste of raw materials, reducing environmental protection emissions, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

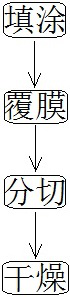

[0031] Refer to attached Figure 1-6 , a kind of processing method of lead-acid accumulator casting polar plate, its step is as follows:

[0032] (1) Filling

[0033] Fill and smear lead paste on the uncut large grid to form a wet plate;

[0034] (2) Lamination

[0035] Double-fold double-sided coating on the surface of the wet plate filled with lead paste (fold in half at the center line of the film, and the film covers the upper and lower surfaces of the grid at the same time);

[0036] (3) Slitting

[0037] Continuous cutting of large pieces of wet plates after coating;

[0038] (4) dry

[0039] Dry the surface of the cut small piece of wet plate.

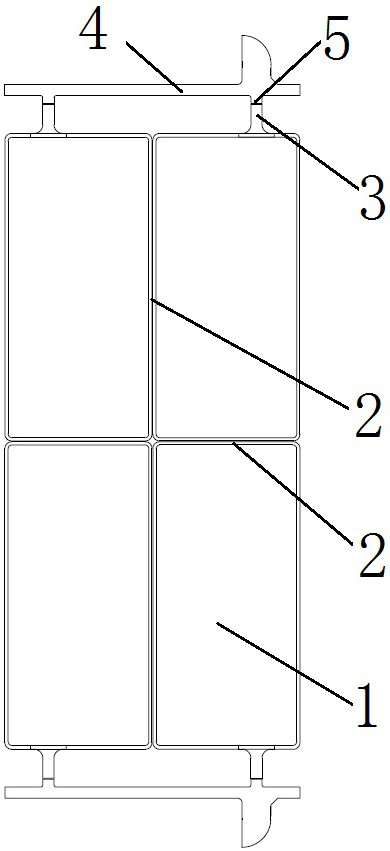

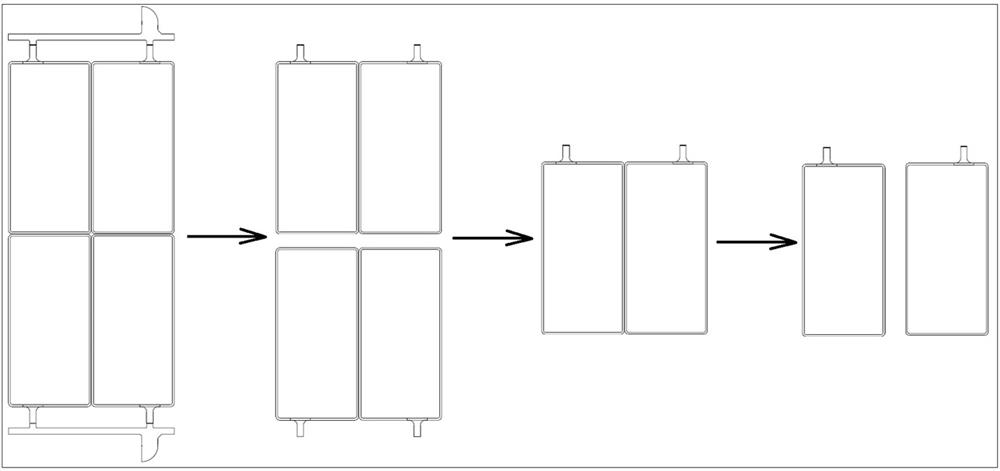

[0040] The uncut pole plate grid is in the shape of matts, and can be cut into four finished pole plates 1 of equal size. There are concave slitting grooves 2 between the finished pole plates 1 for convenience. Carry out slitting; tabs 3 are respectively provided at both ends of both sides of the blank plate, and each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com