Liquid-cooled battery system and control method of liquid-cooled battery system

A liquid-cooled battery and control method technology, which is applied in battery/fuel cell control devices, battery/battery traction, batteries, etc., can solve the impact, potential safety hazards of the whole vehicle, unfavorable safety of the vehicle battery pack, etc. problem, achieve the effect of ensuring safety, improving carrying capacity and avoiding excessive temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

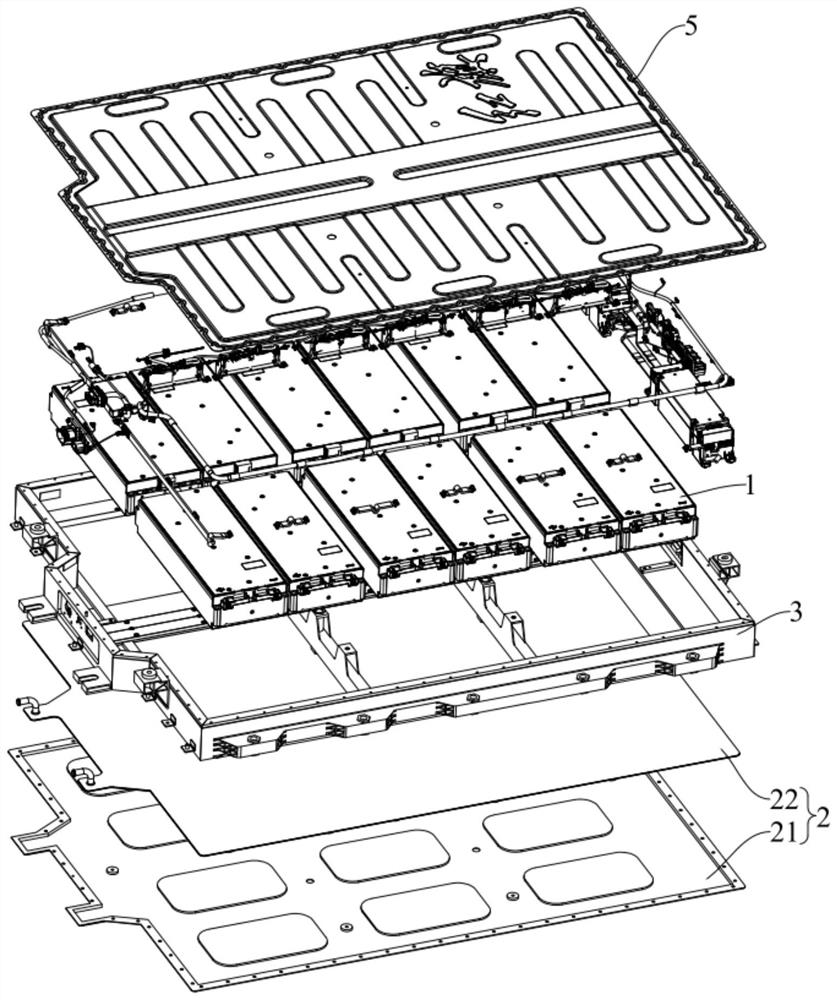

[0049] see Figure 1-Figure 7 , This embodiment provides a liquid-cooled battery system. Specifically, the liquid-cooled battery system is applied to an automobile, which can improve the safety of the battery module and further improve the safety performance of the entire vehicle.

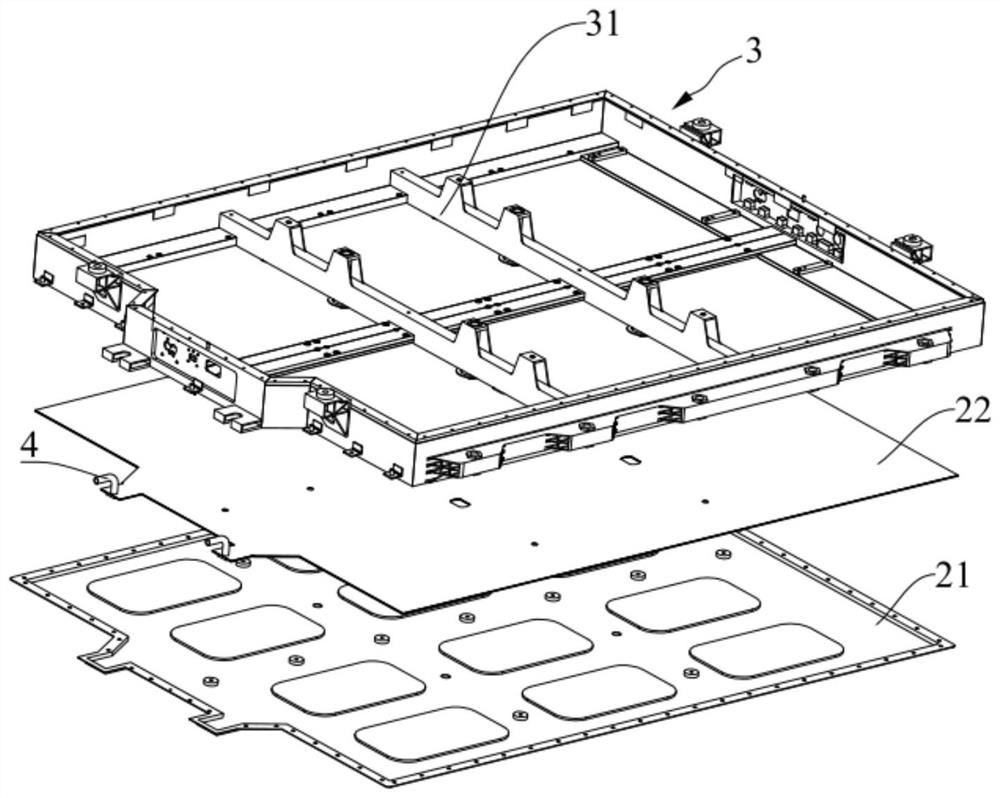

[0050] see figure 1 , figure 2 and Figure 4 , in this embodiment, the liquid-cooled battery system includes a battery module 1 and a cooling bearing part 2 .

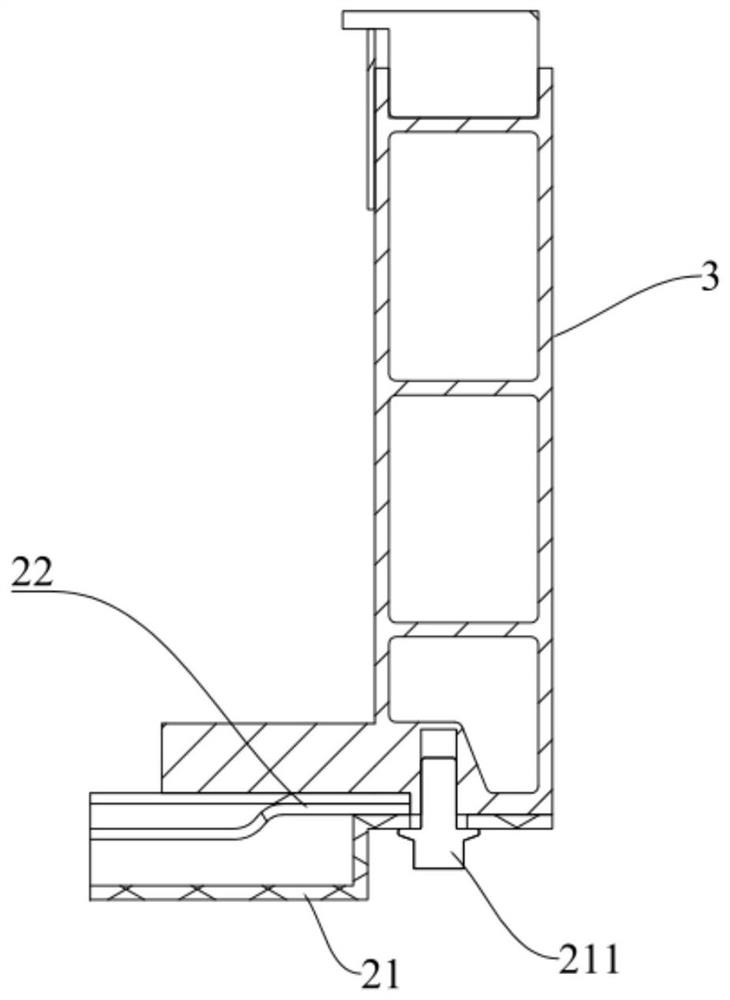

[0051]The cooling bearing part 2 includes a bottom guard plate 21 and a liquid cooling plate 22 arranged on the upper surface of the bottom guard plate 21. The battery module 1 is located on the upper surface of the liquid cooling plate 22. Inside the liquid cooling plate 22, there are several cooling plates along the first direction. The cooling channels 221 are arranged in sequence, and each cooling channel 221 has a liquid inlet and a liquid outlet, and the flow rate in each cooling channel 221 is the same.

[0052] In the liquid-co...

Embodiment 2

[0089] see Figure 8 This embodiment provides a method for controlling a liquid-cooled battery system, which is used to control the liquid-cooled battery system in Embodiment 1 to cool the battery module 1 .

[0090] Specifically, the liquid-cooled battery system further includes a cooling device, which is used to deliver cooling liquid into the liquid-cooled plate 22 . The battery module 1 includes several battery cells 11 .

[0091] The control method of the liquid-cooled battery system includes the following steps:

[0092] S1. Collect the first current temperature of several battery cells 11;

[0093] Specifically, in step S1, if the liquid-cooled battery system includes multiple battery modules 1, the first current temperature of all battery cells 11 is collected.

[0094] S2, judging whether the maximum value of the first current temperature of several batteries 11 is less than the first set temperature, if yes, then perform step S3; if not, then perform step S4;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com