Guide post type electric shock prevention safety charging socket for electric vehicle

A charging socket, electric vehicle technology, applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of large workload of dismantling and debugging, complicated charging process, no universal adaptability, etc., to achieve convenient The effect of one-handed operation, improved safety, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

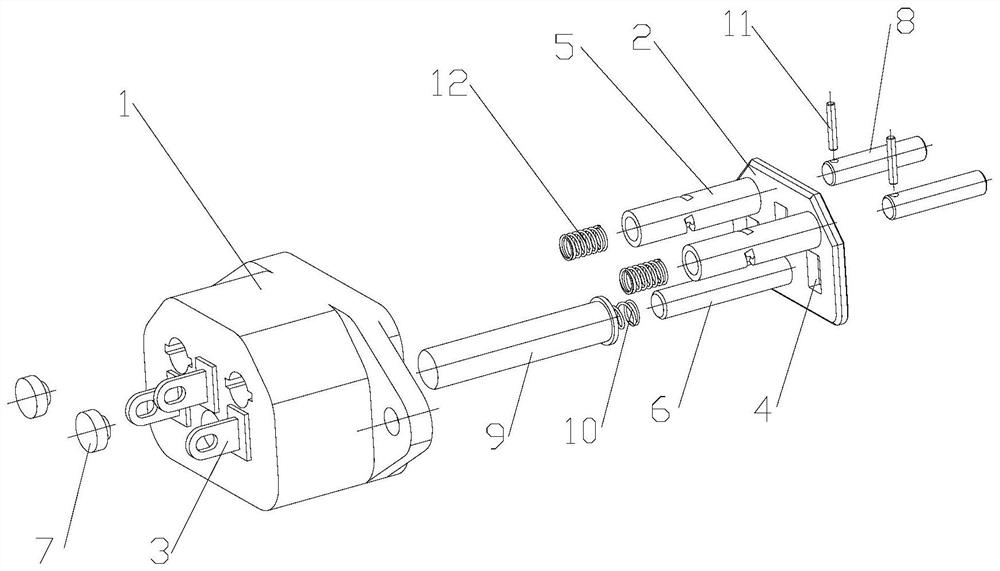

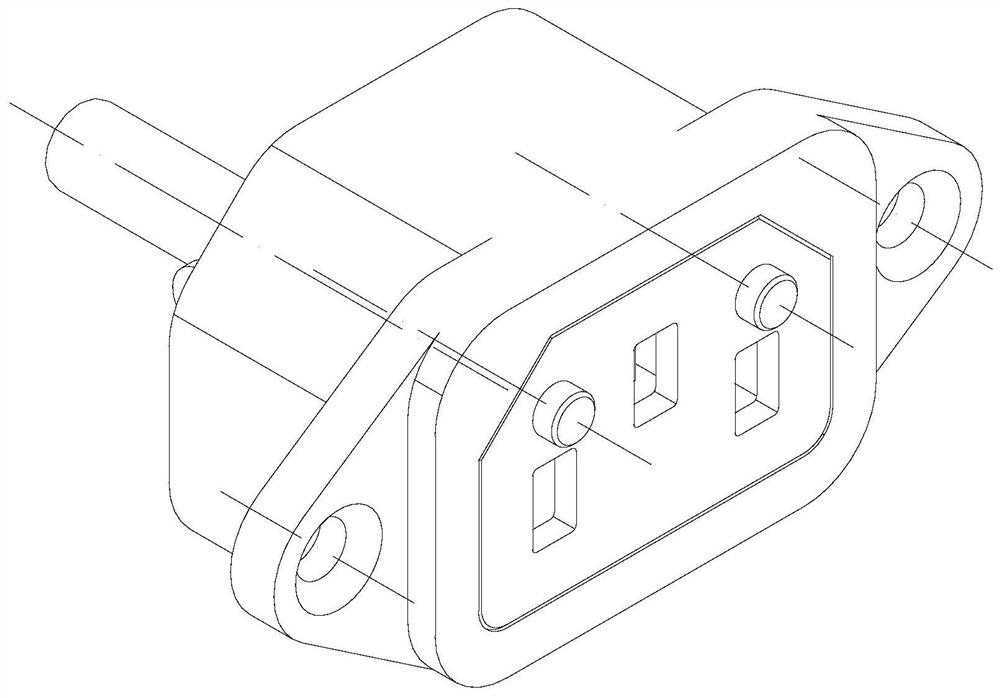

[0015] Such as figure 1 and 2 As shown in the figure, a guide post-type electric vehicle anti-shock safe charging socket includes a charging socket housing 1 and an isolator 2. The charging socket housing 1 is processed with an inner cavity, and a pole is arranged in the inner cavity 3. The pole 3 is installed on the charging socket housing 1, and the pole 3 includes a positive pole, a negative pole and a neutral pole; the isolator 2 is arranged on the surface of the inner concave cavity, and the surface of the isolator 2 is provided with a socket 4, the socket 4 corresponds to the position of the pole 3; the isolator 2 is integrally connected with a guide post 5 and a guide post 6, and the guide post 6 is elastically connected to the charging socket housing 1; the charging at the bottom of the inner concave cavity The body of the socket housing 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com