Battery protection circuit

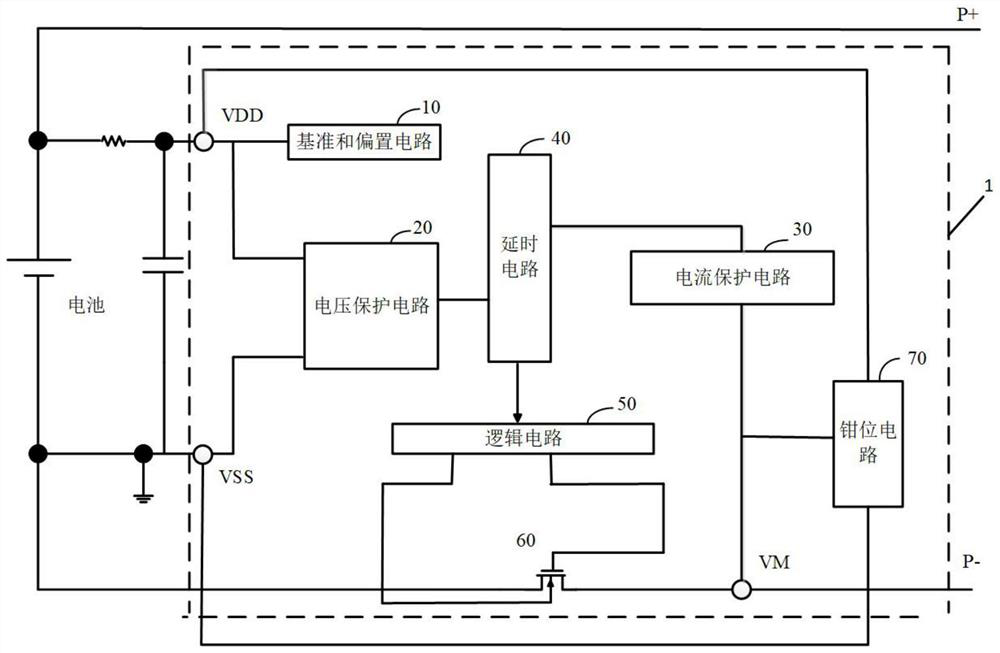

A protection circuit and voltage protection technology, applied in the electronic field, can solve the problems of damage to the chip, increase the chip area and cost, and achieve the effect of reducing the chip area and cost and high withstand voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

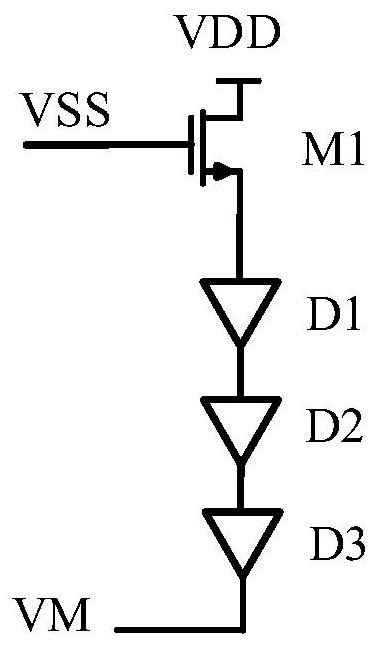

[0060] Optionally, as mentioned above, when the clamping circuit 70 is working, the voltage drop between the second terminal and the third terminal is smaller than the source-drain breakdown voltage VDS of the switch tube. As an implementation manner, the clamping circuit 70 includes an NMOS transistor M1 and a diode string, and the diode string includes several diodes connected in series;

[0061] The drain of the NMOS transistor M1 is connected to the power supply voltage sampling point, the gate is connected to the ground with the negative pole of the battery, and the source is connected to the positive pole of the diode string;

[0062] The cathode of the diode string is connected to the sampling point of the loop current.

[0063] Here, when the clamping circuit 70 is working, the voltage drop between the gate of the NMOS transistor M1 and the cathode of the diode string is smaller than the source-drain breakdown voltage VDS of the switch transistor. The number of diodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com