Fertilizer mixing device for vegetable planting

A mixing device and fertilizer technology, which is applied in the agricultural field, can solve problems such as low production efficiency, inability to meet production needs, and high labor intensity, and achieve the effects of improving work efficiency, facilitating movement, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

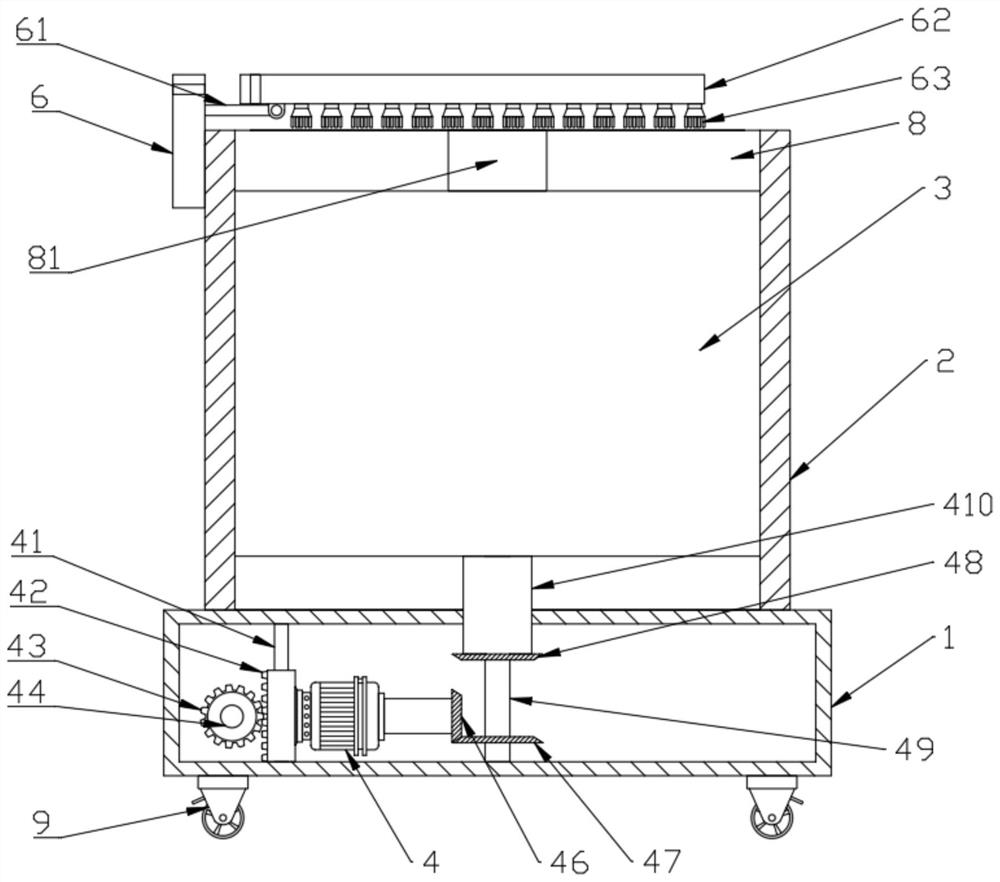

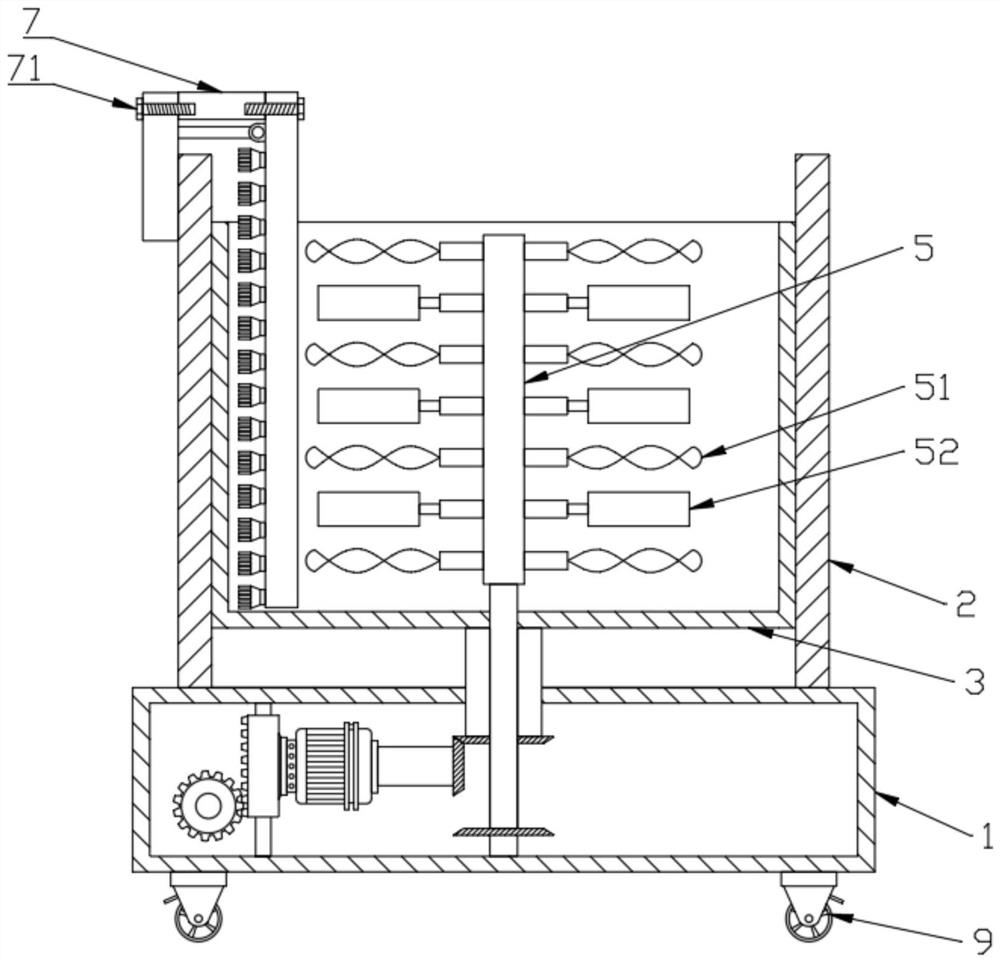

[0024] see Figure 1-4 , a fertilizer mixing device for vegetable planting, comprising a base 1, an outer shell 2 and an inner shell 3, the top surface of the base 1 is fixedly connected to the bottom surface of the outer shell 2, the inner cavity side wall of the outer shell 2 is connected to the inner shell 3 The outer surface of the inner shell 3 is bonded, the outer shell 2 and the inner shell 3 are cylindrical tanks, the inner cavity of the inner shell 3 is provided with a stirring mechanism, and the base 1 is a hollow structure. In addition, a drive mechanism is provided in the hollow cavity, and the stirring mechanism and the drive mechanism are connected to each other. A fixing plate 6 is fixedly connected to the top plate of the side wall of the outer shell 2, and a cleaning mechanism is connected to the fixing plate 6 .

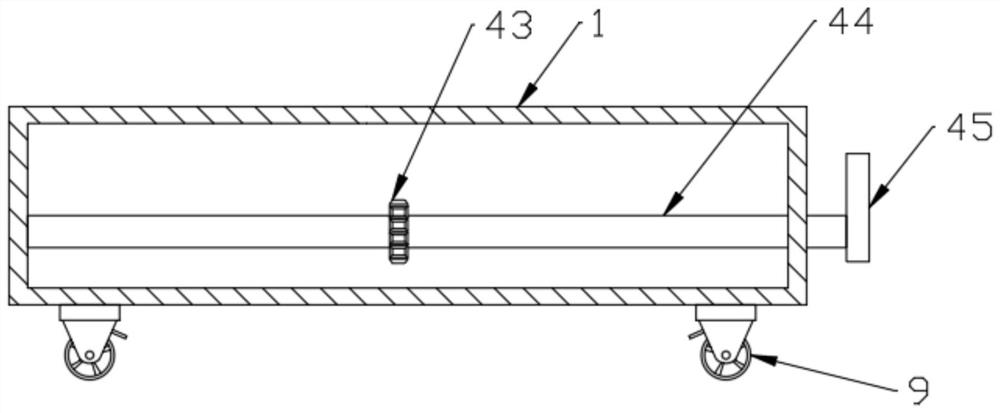

[0025] Described driving mechanism comprises motor 4, support rod 41, rack 42, spur gear 43, rotating rod 44, turning handle 45, first bevel gear 4...

Embodiment 2

[0032] This embodiment is a further improvement made on the basis of Embodiment 1, specifically as follows:

[0033] see Figure 1-4 , the fixed plate 6 is provided with a locking mechanism, the locking mechanism includes an auxiliary plate 7 and a screw 71, the fixed plate 6 and the scraper 62 are provided with threaded through holes, and the fixed plate 6 and The scrapers 62 are threadedly connected to both ends of the auxiliary plate 7 through the screws 71, and after the scraper 62 is rotated to a vertical state, the scrapers 62 are fixed by the screws 71 and the auxiliary plate 7 to prevent scraping. The plate 62 deviates during the cleaning process, so that the brushes 63 cannot contact the inner wall of the inner casing 3, resulting in incomplete cleaning.

[0034] The four corners of the bottom surface of the base 1 are movably connected with universal wheels 9, and the device is conveniently moved by setting the universal wheels 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com