An auxiliary device for engine assembly

An assembly aid and engine technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of frequent use of cranes, time-consuming and laborious, easy to cause safety accidents, etc., to enhance safety, save manufacturing costs, and realize flexible design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment, the present invention is described in further detail:

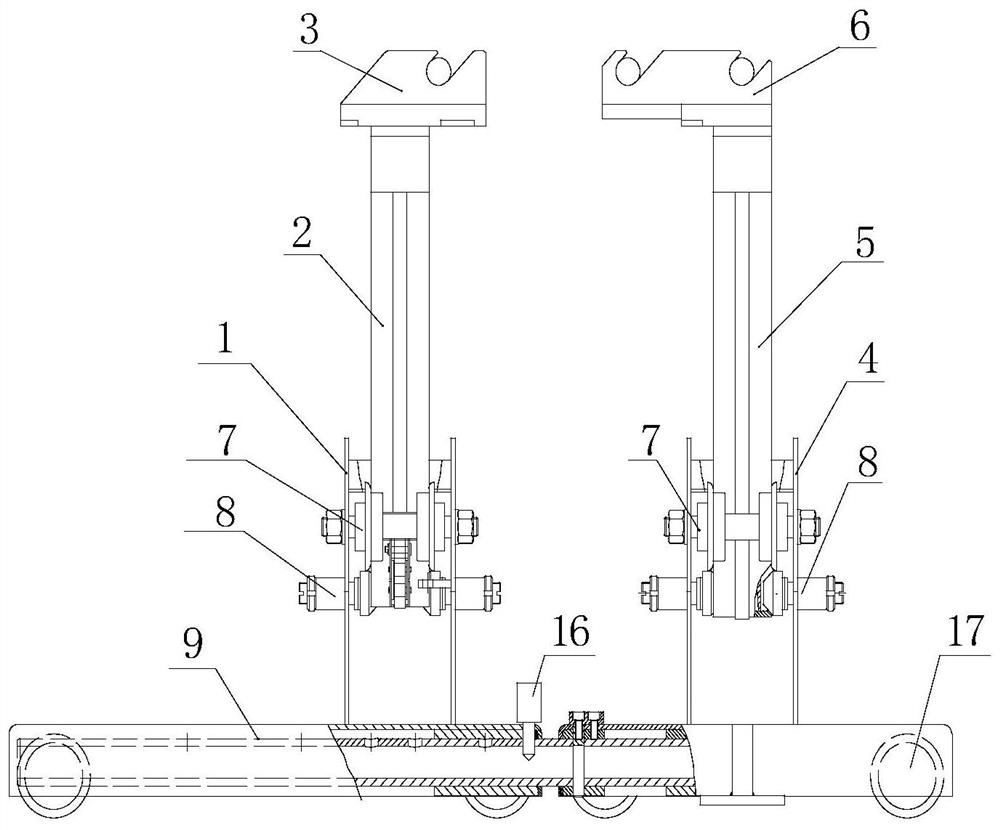

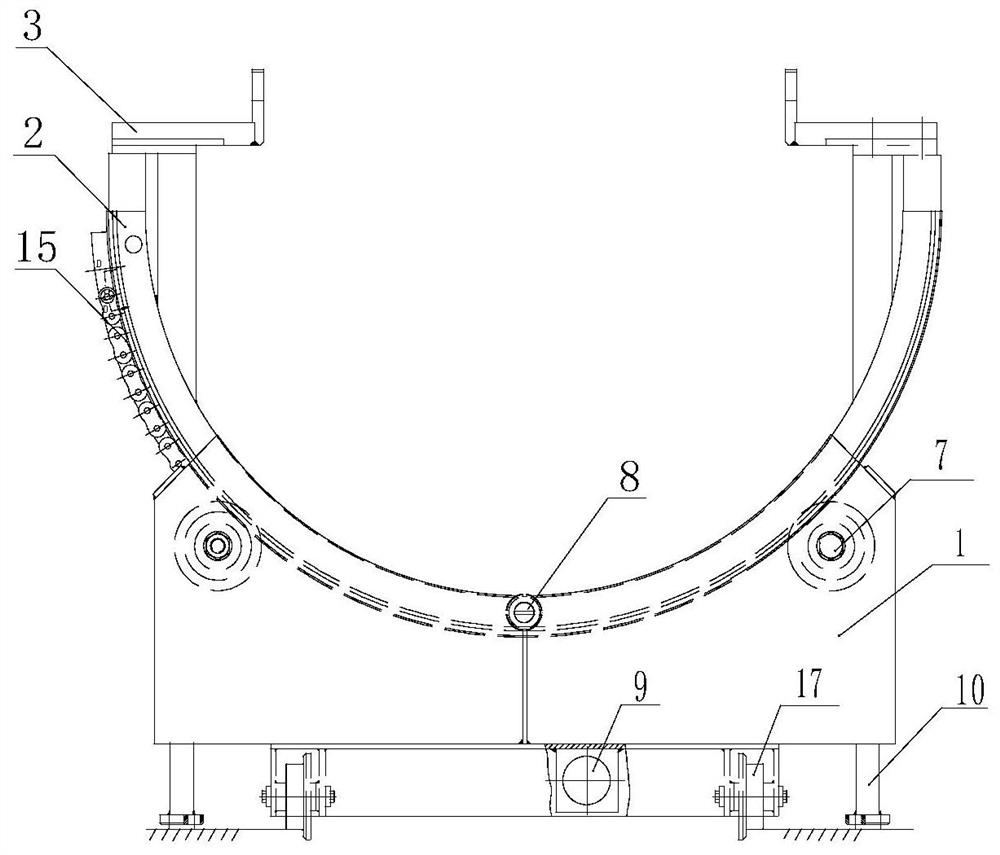

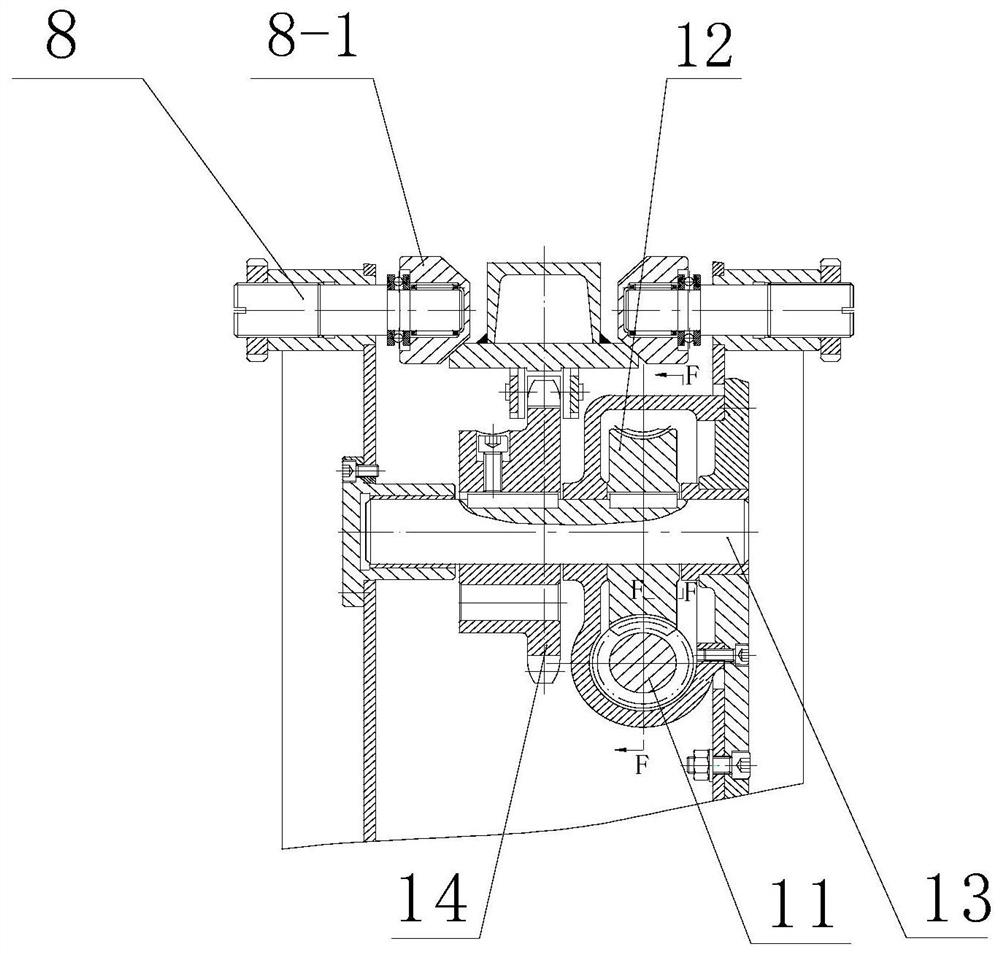

[0023] like Figure 1 to Figure 5 As shown, an engine assembly auxiliary device includes a first auxiliary mechanism and a second auxiliary mechanism. The structures of the first auxiliary mechanism and the second auxiliary mechanism are different, and the first auxiliary mechanism includes a first frame 1, which is movably arranged in The first swivel bracket 2 above the first frame 1 and the first positioning seats 3 fixedly arranged at both ends above the first swivel bracket 2, the first auxiliary mechanism is provided by the first frame 1 and the first swivel The worm gear mechanism between the brackets 2 and the chain sprocket structure are combined for transmission; the worm gear and worm mechanism comprises a worm 11 connected with the output shaft of the motor, and the worm 11 engages the worm wheel 12 through a gear and drives the worm wheel 12 to rotate, The worm wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com