Scallion oil processing device

A processing device and sesame oil technology, which is applied to cleaning devices, metal processing, transportation and packaging, etc., can solve the problems of slow work efficiency and waste of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

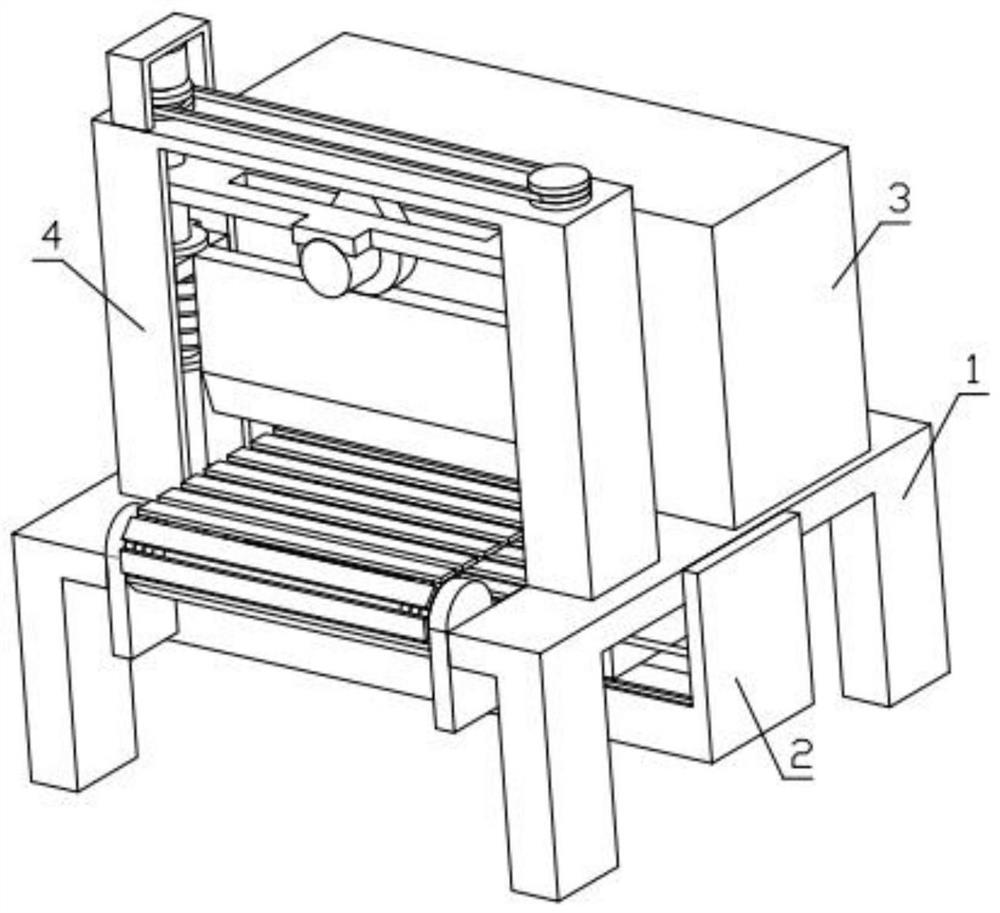

[0032] Combine below Figure 1-13 Description of this embodiment, a processing device for scallion oil, including a transmission mechanism 1, a bottom cleaning mechanism 2, a flattening mechanism 3 and a section cutting mechanism 4, the bottom cleaning mechanism 2 is fixedly installed on the transmission mechanism 1, and the flattening mechanism 3 It is fixedly installed on the transmission mechanism 1, and the section cutting mechanism 4 is fixedly installed on the transmission mechanism 1.

specific Embodiment approach 2

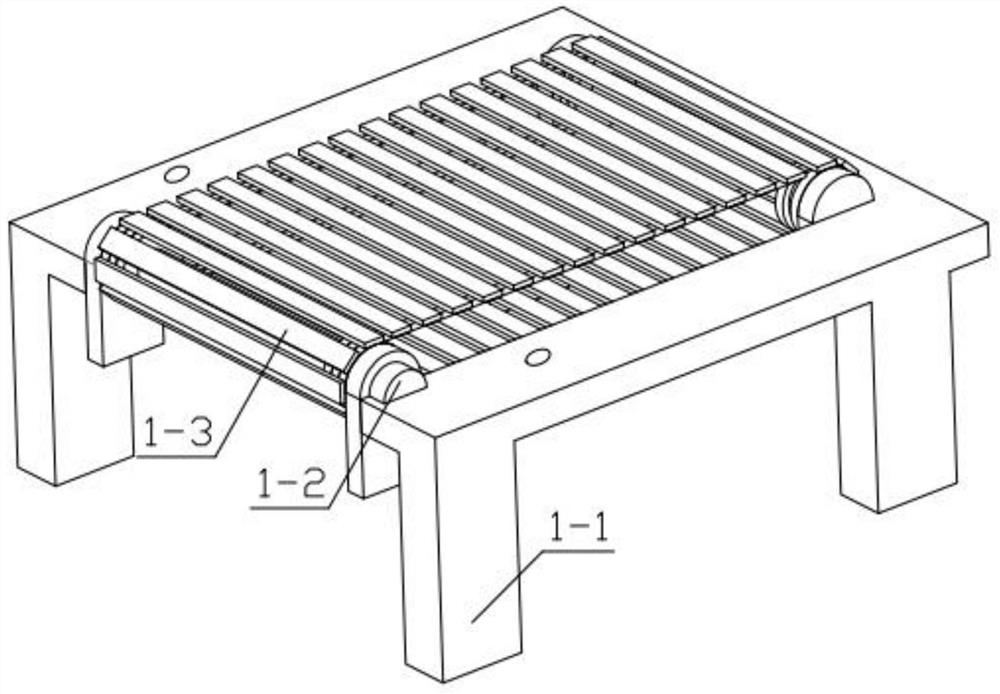

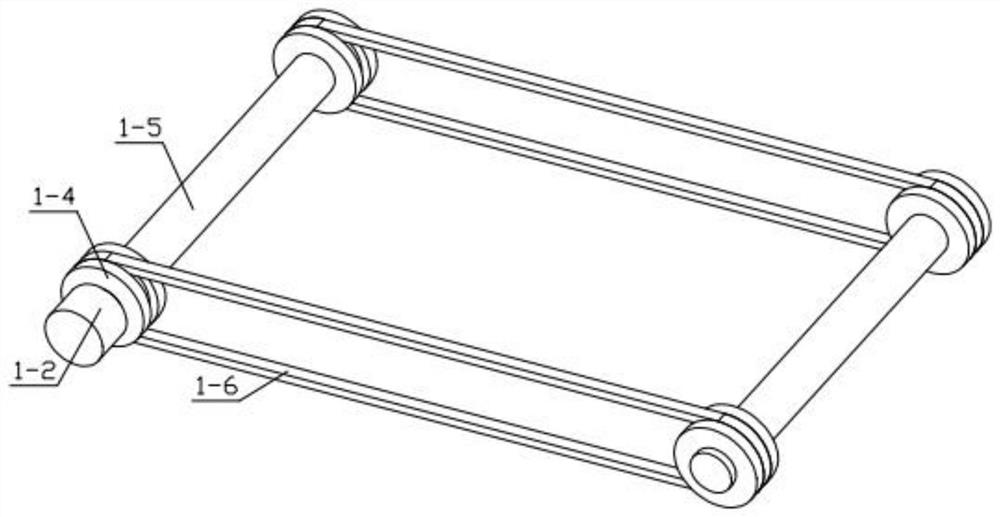

[0034] Combine below Figure 1-13Describe this embodiment, this embodiment will further explain the first embodiment, the transmission mechanism 1 includes a fixed frame 1-1, a transmission motor 1-2, a conveyor belt 1-3, a transmission sprocket 1-4, and a connecting shaft 1 -5, the transmission chain 1-6, the transmission motor 1-2 is fixedly installed in the groove provided on the fixed frame 1-1, the two ends of the connecting shaft 1-5 are respectively fixedly installed with the transmission sprocket 1-4, the transmission The sprocket 1-4 is rotatably installed in the groove provided on the fixed frame 1-1, and one of the transmission sprockets 1-4 is fixedly installed on the output end of the transmission motor 1-2, and the transmission sprocket 1-4 is connected with the transmission The chains 1-6 are meshed, and the conveyor belt 1-3 is fixedly installed on the conveyor chain 1-6.

specific Embodiment approach 3

[0036] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the second embodiment, the bottom cleaning mechanism 2 includes a sink part 2-1, a cleaning motor 2-2, a fixed block 2-3, and a cleaning shaft brush 2-4 , fixed block two 2-5, limit rod 2-6, sliding frame 2-7, rolling brush 2-8, rolling brush motor 2-9, moving gear one 2-10, moving gear two 2-11, sink parts 2-1 is fixedly installed on the fixed frame 1-1, fixed block one 2-3 is fixedly installed on one side of the fixed frame 1-1, fixed block two 2-5 is fixedly installed on the other side of the fixed frame 1-1, The cleaning motor 2-2 is fixedly installed in the through hole of the fixed block 1 2-3, and one end of the cleaning shaft brush 2-4 is fixedly mounted on the output end of the cleaning motor 2-2, and the other end of the cleaning shaft brush 2-4 The rotation is installed in the groove provided on the fixed block two 2-5, the limit bar 2-6 is fixedly installed on the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com