Sedimentation tank for sewage treatment

A technology for sewage treatment and sedimentation tank, applied in the field of sedimentation tank, can solve the problem that the SS value of the effluent is difficult to meet the requirements and affect the quality of the effluent, and achieve the effect of reducing the configuration of the sludge return pump and saving the volume of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

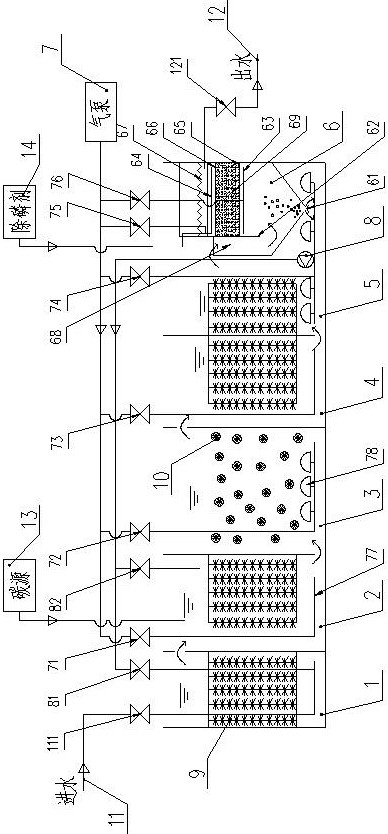

[0025] A sewage treatment device, comprising an anaerobic pool 1, a primary anoxic pool 2, a primary aerobic pool 3, a secondary anoxic pool 4, a secondary aerobic pool 5, a sedimentation tank 6, and a primary anoxic pool 2 , first-level aerobic tank 3, second-level anoxic tank 4, and second-level aerobic tank 5 pass through the first-level anoxic zone intake valve 71, the first-level aerobic zone intake valve 72, and the second-level anoxic zone intake valve respectively. The valve 73 and the air intake valve 74 in the secondary aerobic zone control the air supply to the bottom of each zone through the air pump 7, and the water inlet pipe 11 supplies water to the anaerobic pool 1 through the pipeline, and the water intake is controlled by the anaerobic zone water inlet control valve 111; The bottom of the primary aerobic tank 5 supplies the mixed liquid to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com