A kind of synthetic method of artificial turf fiber surface modification functional gel

A technology of fiber surface and artificial turf, applied in the direction of fiber treatment, fiber type, chemical instruments and methods, etc., can solve the problems of cumbersome gel coating steps, reduce environmental stress cracking, superior softness, improve stickiness Adjunctive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

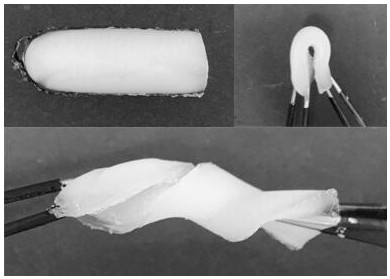

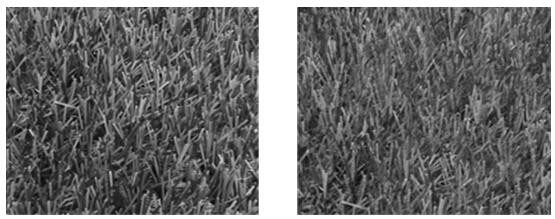

Image

Examples

Embodiment 1

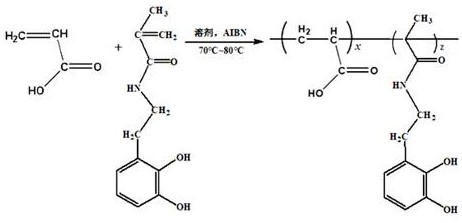

[0043] (1) Preparation of dopamine functional monomer containing double bond

[0044] Dissolve 10 g of sodium borate decahydrate and 4 g of sodium bicarbonate in 100 mL of distilled water, and after degassing by nitrogen bubbling for 20 minutes, add 5 g of dopamine hydrochloride and stir well. 4.7 mL of methacrylic anhydride / THF (25 mL) solution was slowly added dropwise to the above mixed aqueous solution; the pH value of the aqueous solution was adjusted to ≥8 with NaOH, and the reaction mixture was stirred at room temperature for 14 h under nitrogen bubbling. The resulting white slurry solution was washed twice with 50 mL of ethyl acetate, filtered, and the resulting aqueous solution was acidified with 6 mol / L HCl to pH = 2; the organic layer in the solution was extracted with 50 mL of ethyl acetate for 3 times, concentrated by a rotary evaporator, Add dropwise to 250 mL of n-hexane for precipitation, filter, and vacuum-dry to obtain a brown solid product.

[0045] (2) Pre...

Embodiment 2

[0056] (1) Preparation of dopamine functional monomer containing double bond

[0057] Dissolve 10 g of sodium borate decahydrate and 4 g of sodium bicarbonate in 100 mL of distilled water, and after degassing by nitrogen bubbling for 20 minutes, add 5 g of dopamine hydrochloride and stir well. 4.7 mL of methacrylic anhydride / THF (25 mL) solution was slowly added dropwise to the above mixed aqueous solution; the pH value of the aqueous solution was adjusted to ≥8 with NaOH, and the reaction mixture was stirred at room temperature for 14 h under nitrogen bubbling. The resulting white slurry solution was washed twice with 50 mL of ethyl acetate, filtered, and the resulting aqueous solution was acidified with 6 mol / L HCl to pH = 2; the organic layer in the solution was extracted with 50 mL of ethyl acetate for 3 times, concentrated by a rotary evaporator, Add dropwise to 250 mL of n-hexane for precipitation, filter, and vacuum-dry to obtain a brown solid product.

[0058] (2) Pre...

Embodiment 3

[0063] (1) Preparation of dopamine functional monomer containing double bond

[0064] Dissolve 10 g of sodium borate decahydrate and 4 g of sodium bicarbonate in 100 mL of distilled water, and after degassing by nitrogen bubbling for 20 minutes, add 5 g of dopamine hydrochloride and stir well. 4.7 mL of methacrylic anhydride / THF (25 mL) solution was slowly added dropwise to the above mixed aqueous solution; the pH value of the aqueous solution was adjusted to ≥8 with NaOH, and the reaction mixture was stirred at room temperature for 14 h under nitrogen bubbling. The resulting white slurry solution was washed twice with 50 mL of ethyl acetate, filtered, and the resulting aqueous solution was acidified with 6 mol / L HCl to pH = 2; the organic layer in the solution was extracted with 50 mL of ethyl acetate for 3 times, concentrated by a rotary evaporator, Add dropwise to 250 mL of n-hexane for precipitation, filter, and vacuum-dry to obtain a brown solid product.

[0065] (2) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com