Lint removing device for textile fabric printing and dyeing

A technology for textile fabrics and printing, which is applied to the field of hair removal devices for printing and dyeing textile fabrics, can solve problems such as troublesome fixing, reduced practicability, and inconvenience to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

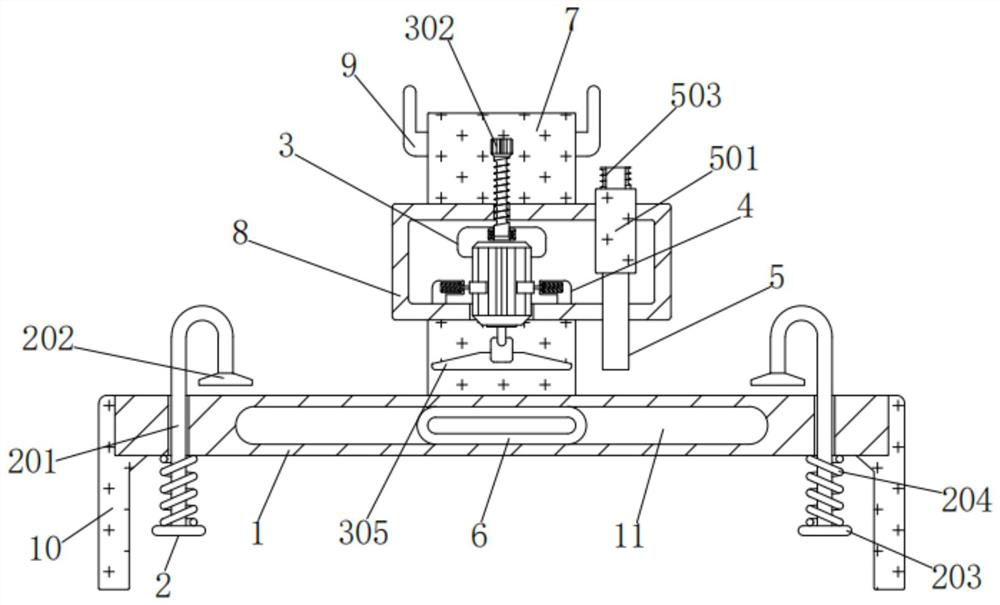

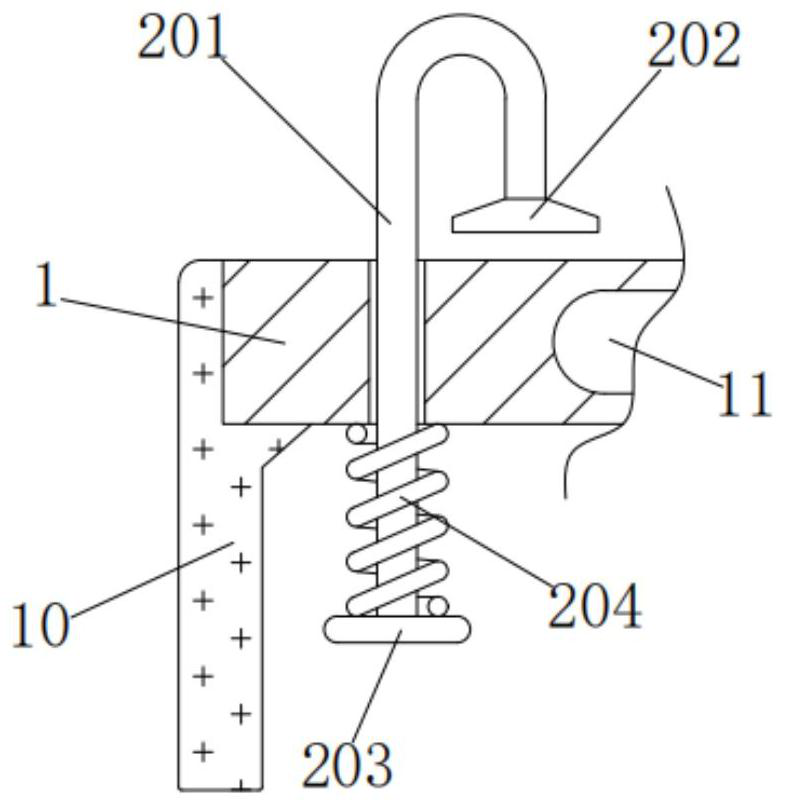

[0038] A hair removal device for printing and dyeing of textile fabrics, comprising a base plate 1, a fixing mechanism 2 is installed on the left and right sides of the front of the base plate 1, and the fixing mechanism 2 includes a curved rod 201, a curved block 202, a short plate 203 and a first spring 204, The outer wall of the curved rod 201 is matched with the front left side of the bottom plate 1. The curved rod 201 moves up and down through the front left side of the bottom plate 1 under force. It is fixedly connected with the top of the short plate 203, and the lower part of the outer wall of the curved rod 201 is socketed with the inner wall of the first spring 204. Fixed connection, the curved rod 201, the short plate 203, the first spring 204 and the bottom plate 1 form a telescopic mechanism, and the curved rod 201 rebounds through the first spring 204 after being moved under force;

[0039] The front of the bottom plate 1 is processed with a chute 11, the inner w...

Embodiment 2

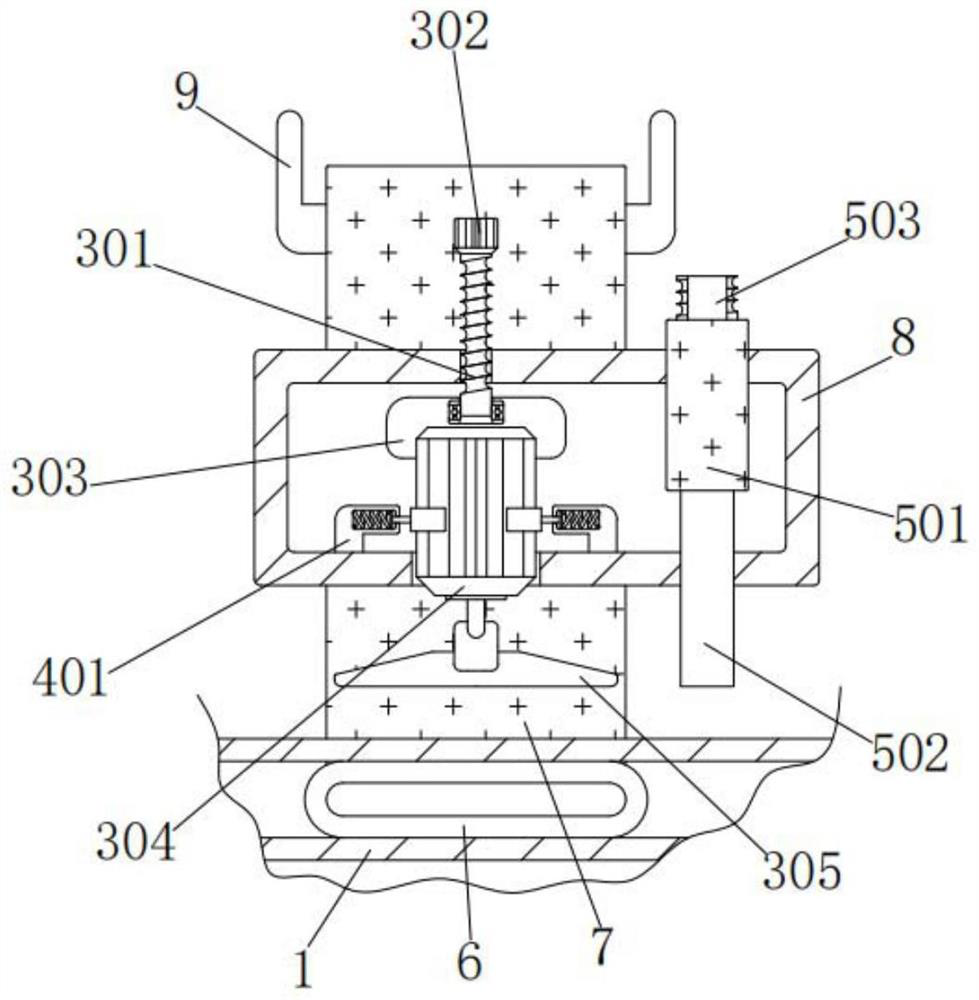

[0041] As an option, see figure 1 , 3 And 4, textile fabric printing and dyeing hair removal device, the inwall of square frame 8 is equipped with power mechanism 3, and power mechanism 3 comprises threaded rod 301, handle 302, support 303, motor 304 and cutter 305, and the outer wall of threaded rod 301 and The top threaded connection of square frame 8, the top of threaded rod 301 is fixedly connected with the bottom of handle 302, and handle 302 is convenient to rotate threaded rod 301, and the bottom of threaded rod 301 is connected with the top of support 303 rotation, and the bottom of threaded rod 301 The force is rotated through the bearing on the top of the support 303. The inner wall of the support 303 is fixedly connected to the top of the outer wall of the motor 304. The model of the motor 304 is Y2-1. The lower part of the outer wall of the motor 304 is matched with the bottom of the square frame 8. Power moves up and down through the bottom of the square frame 8,...

Embodiment 3

[0044] As an option, see figure 1 , 4 And 5, the hair removal device for printing and dyeing of textile fabrics, the left and right sides of the inner wall bottom of the square frame 8 are equipped with a protection mechanism 4, and the protection mechanism 4 includes a curved plate 401, a second spring 402, a protruding rod 403 and a circular arc plate 404 , the bottom of the bent plate 401 is affixed to the bottom left side of the inner wall of the square frame 8, the left side of the inner wall above the front of the bent plate 401 is affixed to the left side of the second spring 402, and the right side of the second spring 402 is affixed to the protruding rod The left side of 403 is fixedly connected, and the protruding rod 403 rebounds through the second spring 402 after being moved under force. The outer wall of the protruding rod 403 cooperates with the gap on the right side of the inner wall above the front of the curved plate 401, and the protruding rod 403 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com