Clothes hanger mounting structure of assembled balcony

A technology for installing structures and drying racks, which is applied to washing devices, other drying devices, textiles and papermaking, etc. It can solve the problems of poor decoration effect, abnormal noise clothes, shaking, etc., achieve high structural stability, ensure aesthetics, Avoid the effect of structural shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

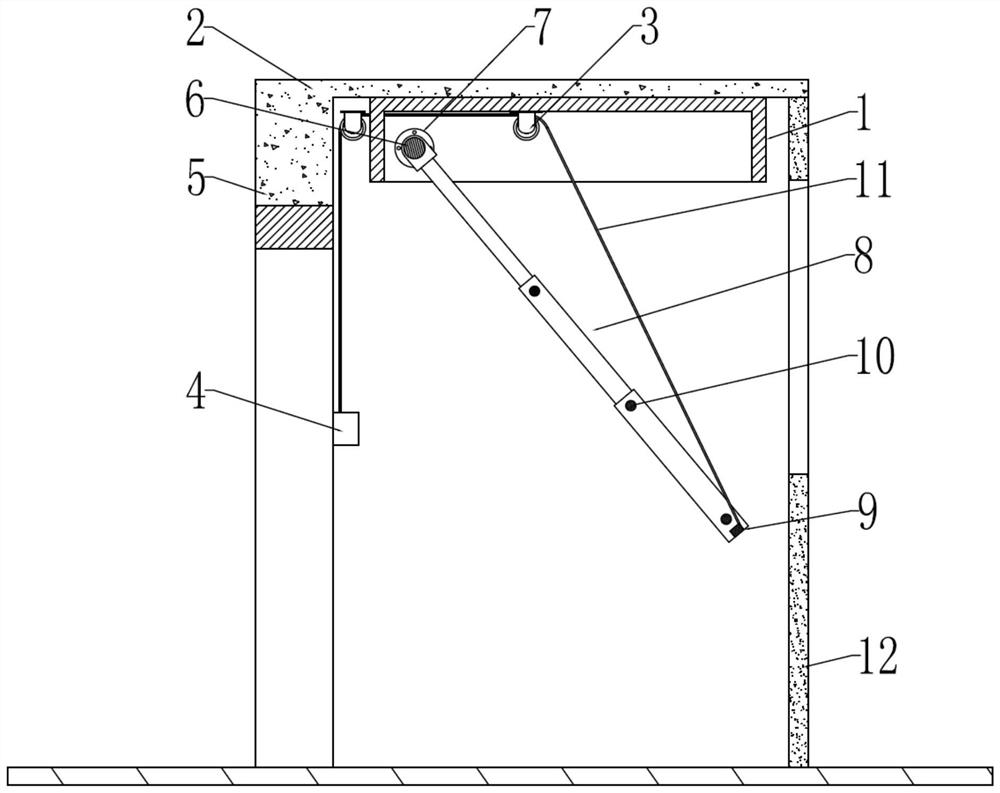

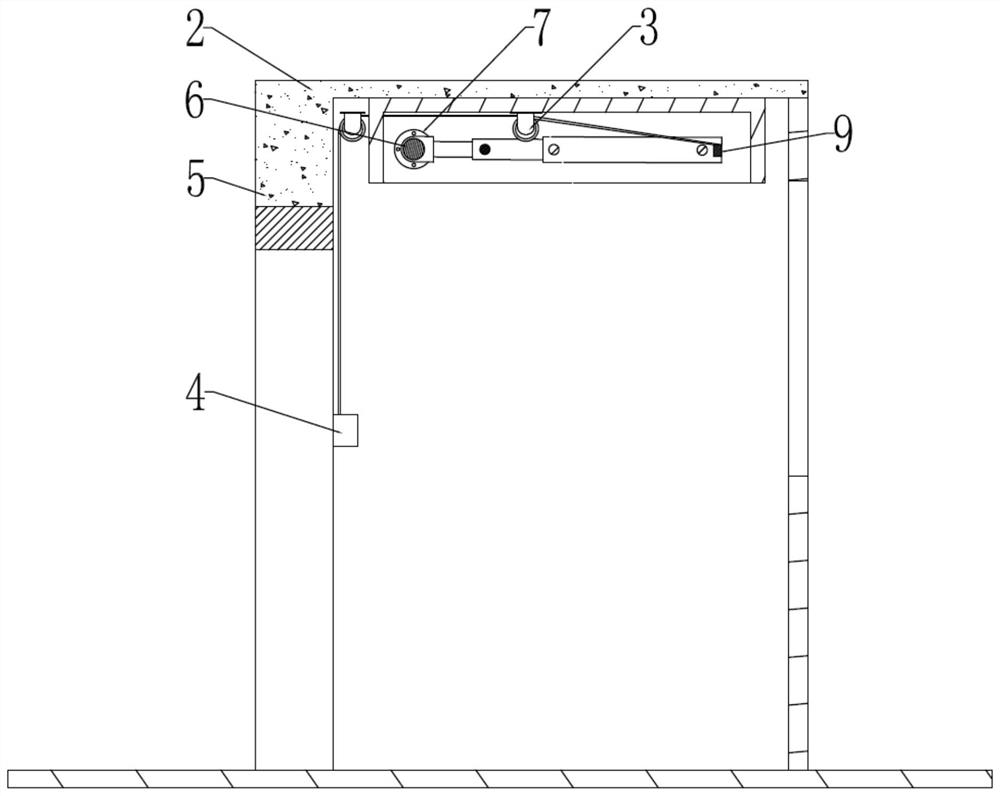

[0029] see Figure 1 to Figure 4 , the present embodiment provides a clothes hanger installation structure for a prefabricated balcony, wherein firstly a fixing groove 1 is provided, which is a cuboid groove with the opening end facing downwards, and the top surface of the fixing groove 1 is fixedly connected to the base layer 2 of the top wall , a guide wheel 3 is arranged on the top of the fixed groove 1; a hand crank 4 is fixedly connected to the partition wall 5;

[0030] Fixed rod 6, its two ends extend to the opposite side walls in the fixed groove 1, the end of the fixed rod 6 is connected with the fixed groove 1 through the bearing seat 7; One end of 8 is fixedly connected on the fixed rod 6, and the other ends of the two telescopic rod mechanisms 8 are connected with a support rod 9, and there are many clothes rails 10 connected between the two telescopic rod mechanisms 8; the traction rope 11, which wears Through the guide wheel 3 , one end of the traction rope 11 i...

Embodiment 2

[0037] see Figure 1 to Figure 4 , the figure shows a clothes hanger installation structure of a prefabricated balcony provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: guide wheels 3 Located above the telescopic rod mechanism 8.

[0038] Specifically, see Figure 1 to Figure 4 , The angle between the telescopic rod mechanism 8 and the top wall base 2 is 0°-40°.

[0039] Guide wheel 3 is arranged on the top of telescopic rod mechanism 8, when guaranteeing that traction rope 11 is pulled to certain state, can guarantee that telescopic rod mechanism 8 is in horizontal state.

Embodiment 3

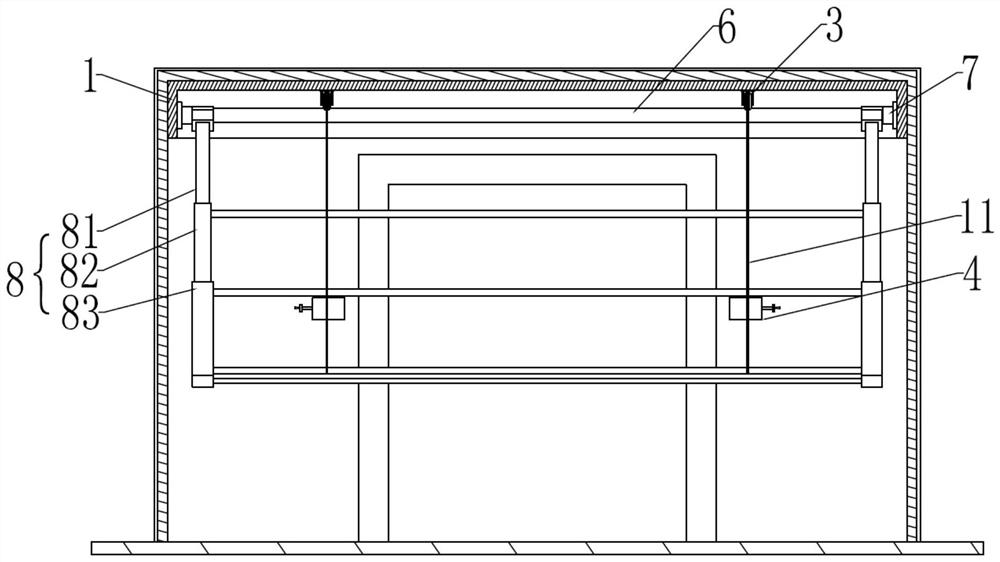

[0041] see Figure 1 to Figure 4 , the figure shows a clothes hanger installation structure of a prefabricated balcony provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: telescopic rod mechanism 8 includes a first connecting rod 81, a second connecting rod 82 and a third connecting rod 83, the second connecting rod 82 is sleeved on the first connecting rod 81, the third connecting rod 83 is sleeved on the second connecting rod 82, The end of the first connecting rod 81 is fixedly connected to the fixed rod 6 , and the support rod 9 is fixedly connected to the end of the third connecting rod 83 .

[0042] Specifically, see Figure 1 to Figure 4 , the length of the first link 81, the length of the second link 82 and the length of the third link 83 are equal.

[0043] Specifically, see Figure 1 to Figure 4 , the clothes-horse 10 is located at the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com