Automatic speed change electro-hydraulic control valve of tractor

An electro-hydraulic control valve, automatic speed change technology, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of poor safety performance, high labor intensity, high failure rate, and improve safety performance, reduce Labor-intensive, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

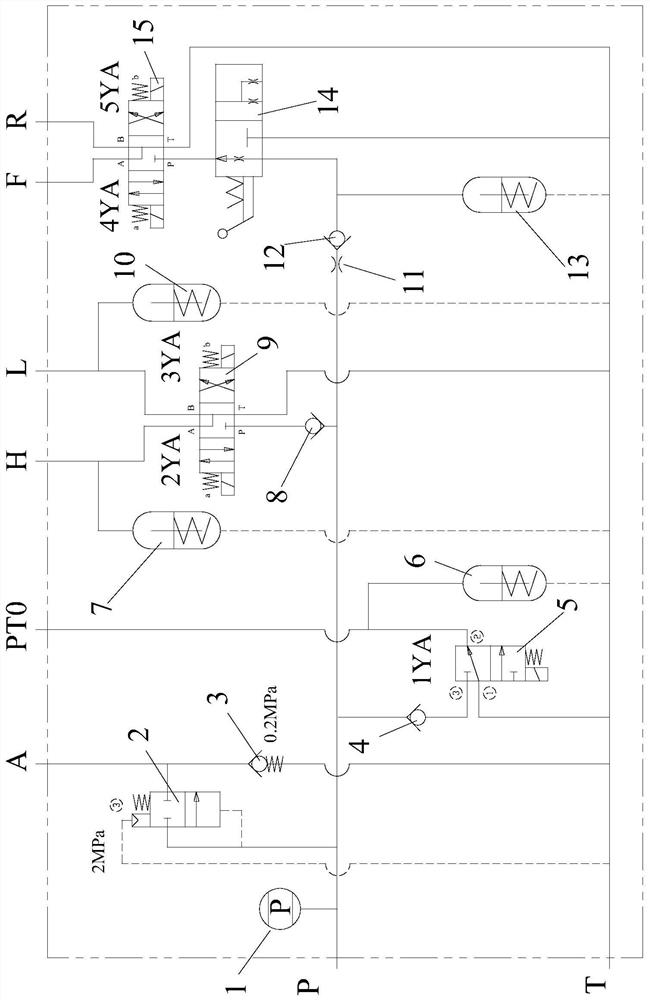

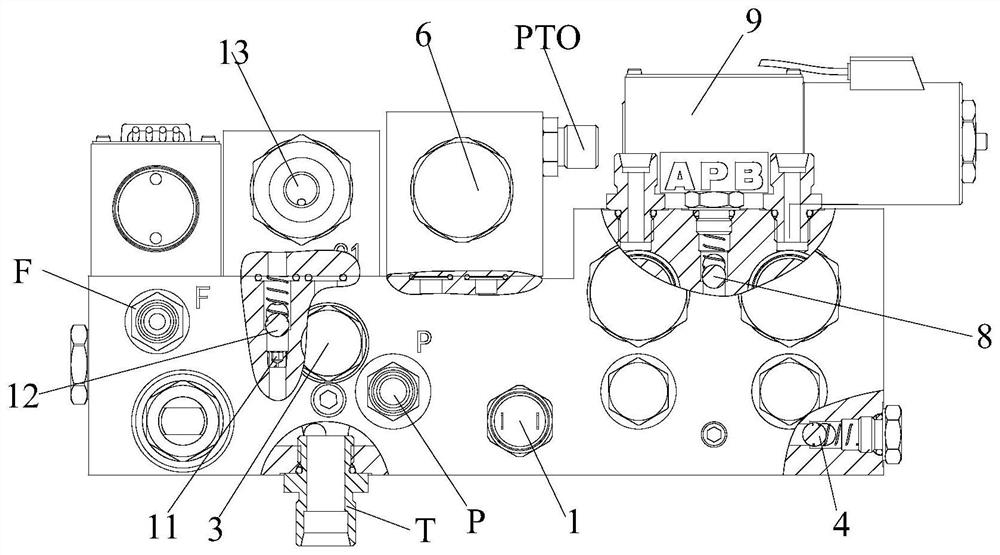

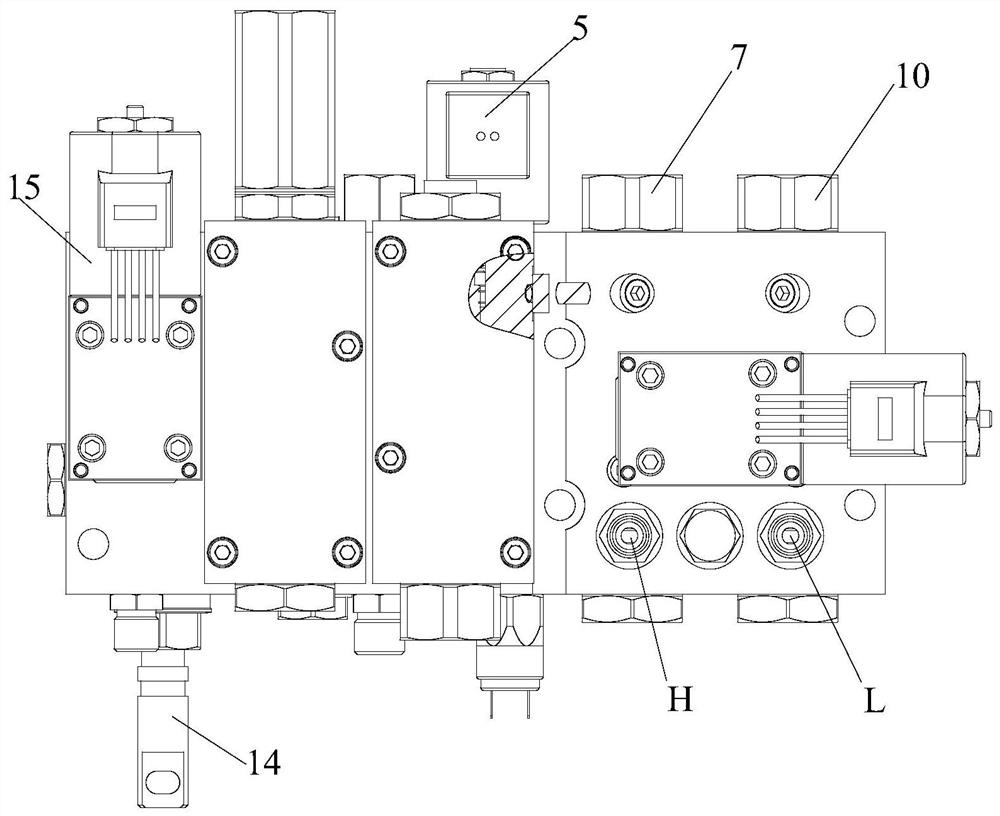

[0027] Figure 1-Figure 4 Some embodiments according to the invention are shown.

[0028] Such as Figure 2-4 As shown, an automatic variable speed electro-hydraulic control valve for a tractor includes a valve body and several valve blocks arranged on the valve body. Different valve blocks can realize different functions. These valve blocks specifically include hydraulic control logic valves, micro Actuated valves, electromagnetic reversing valves, accumulator valves, and check valves; through the cooperation of different valve blocks, functions such as front and rear gear switching, high and low speed switching, lubrication, and power output PTO of the tractor can be realized.

[0029] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com