Card feeding device in card making machine and card feeding method thereof

A card-making machine and card-feeding technology, which is applied to computer parts, transmission record carriers, instruments, etc., can solve problems such as the reduction of card-making efficiency, and achieve the effect of improving card-making efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

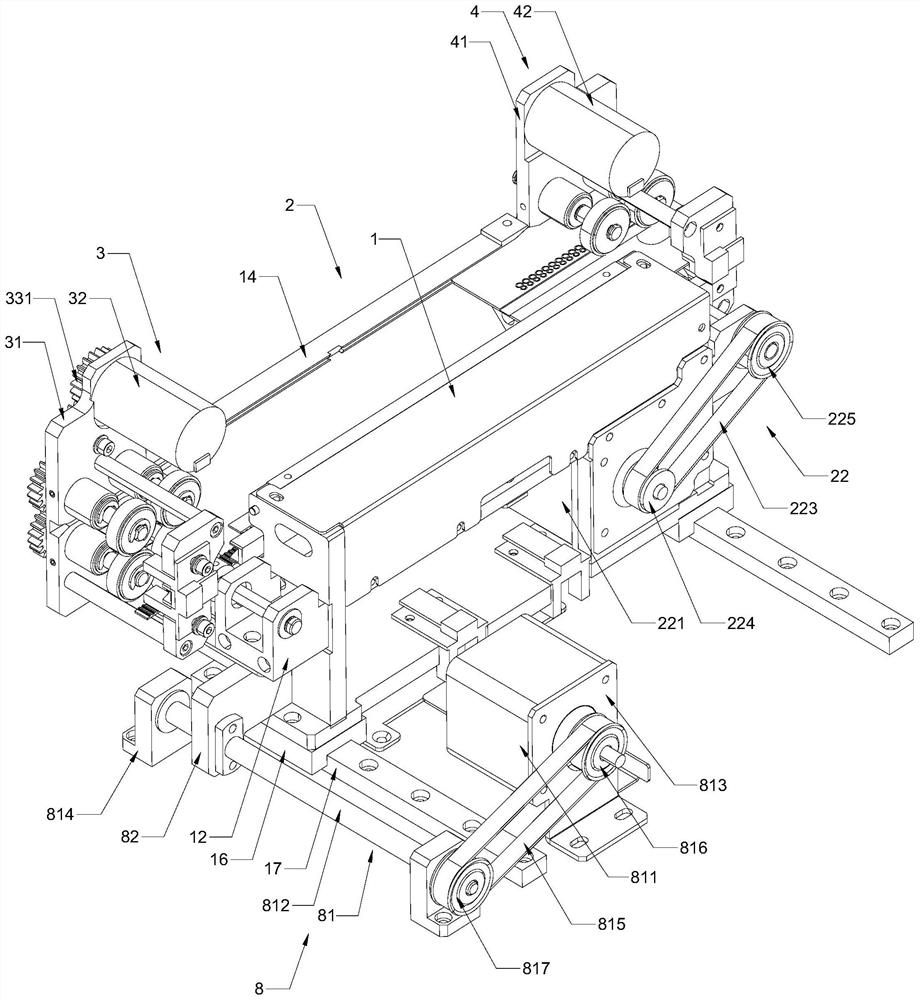

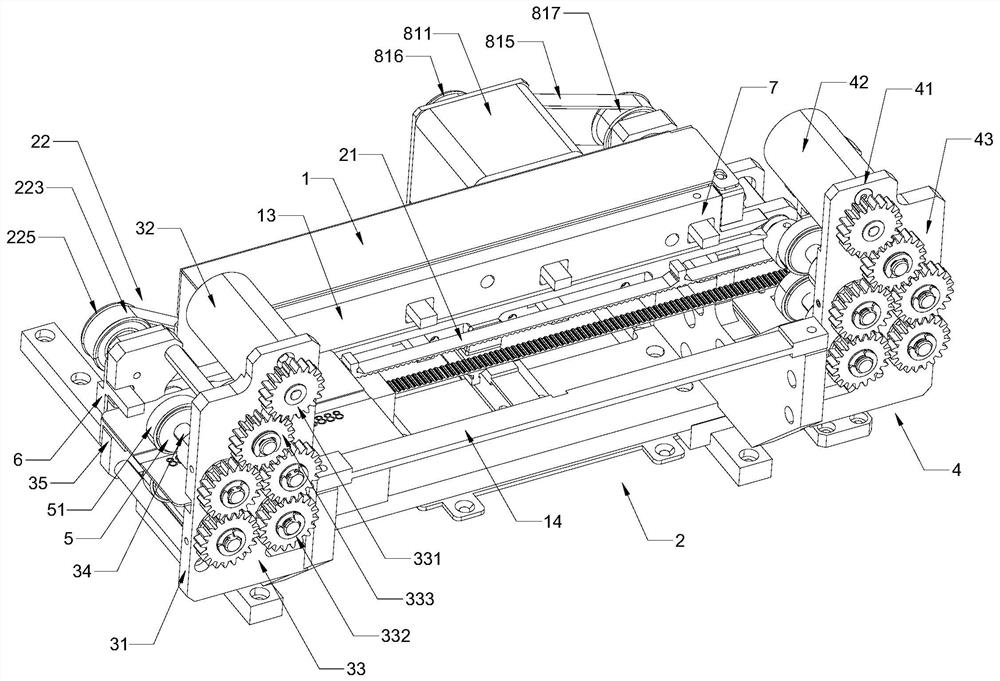

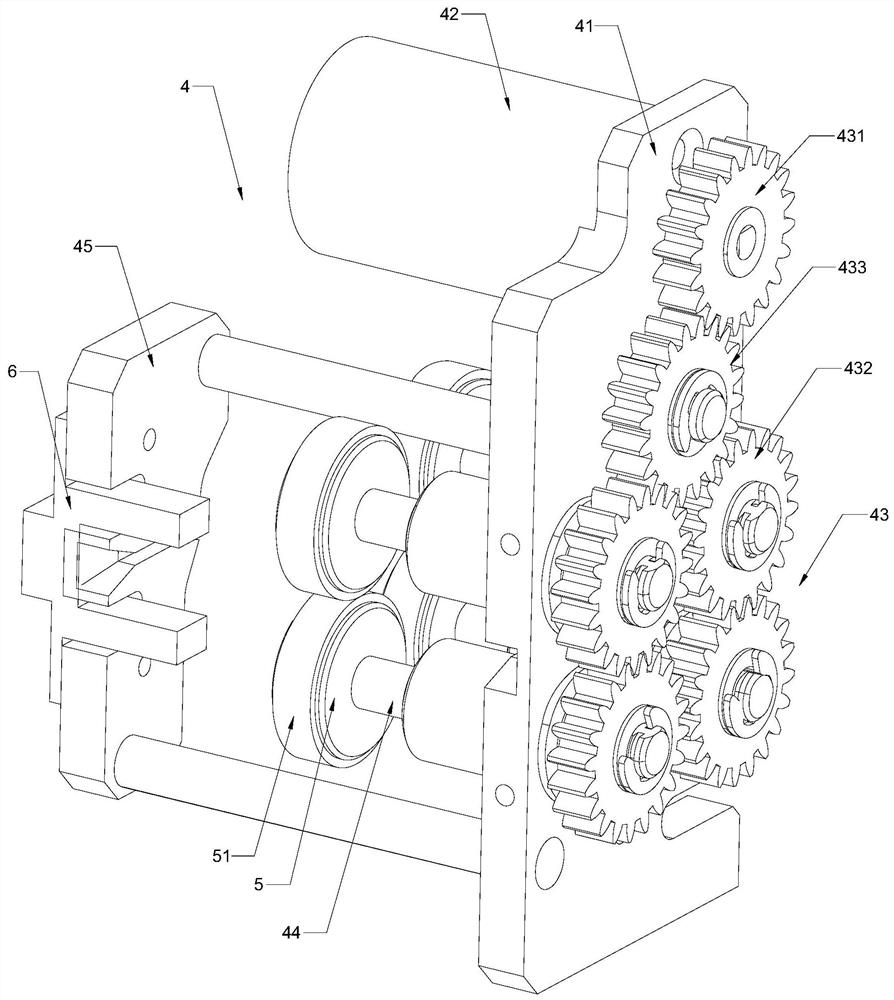

[0043] refer to Figure 1 to Figure 6 As shown, it is a specific embodiment of the card feeding device in a card making machine of the present invention, including a frame 1, the frame 1 is erected on the work surface, and the frame 1 is provided with a card feeding mechanism 2 for conveying cards One end of the frame 1 is provided with a first card pushing mechanism 3 for card feeding operation, which is used to transport cards into the card feeding mechanism 2, and the other end is provided with a second card pushing mechanism 4 for card output operation, which is used for printing After the card is sent out, the card output operation is realized. The first card pushing mechanism 3 and the second card pushing mechanism 4 are all provided with an end position detection grating 6 for detecting the card. When the end position detection grating 6 detects the card blocking signal, start the first card pushing mechanism 3 to transport the card into the card feeding mechanism 2, an...

Embodiment 2

[0055] The difference from Embodiment 1 is that it is a specific embodiment of the card feeding method of the card feeding device of a card making machine according to the present invention, which includes the following steps:

[0056] S1: When the end position detection grating 6 in the first card pushing mechanism 3 does not detect the card blocking signal, the first card pushing mechanism 3 does not start, and when the end position detection in the first card pushing mechanism 3 When the grating 6 detects the card blocking signal, start the first card pushing mechanism 3 to send the card, send the card to the card feeding mechanism 2, and enter the next step;

[0057] S2: When the frame 1 is close to the position detection grating of the first card pushing mechanism 3 and detects the card blocking signal, the transmission part 22 in the card feeding mechanism 2 starts and drives the card feeding part 21 to send the card. The card feeding direction is toward the second card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com