Intelligent regulation and control method for bag-feeding type food full-automatic packaging machine

A fully automatic packaging machine, packaging machine technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of error, low accuracy, low production efficiency of packaging machines, etc., achieve good robustness and improve work efficiency , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

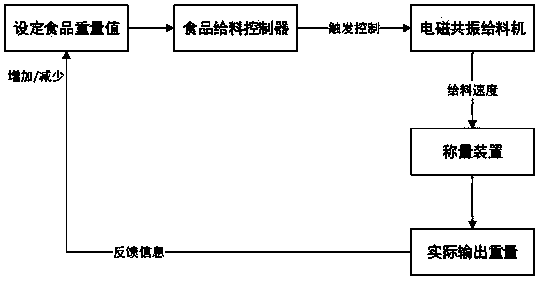

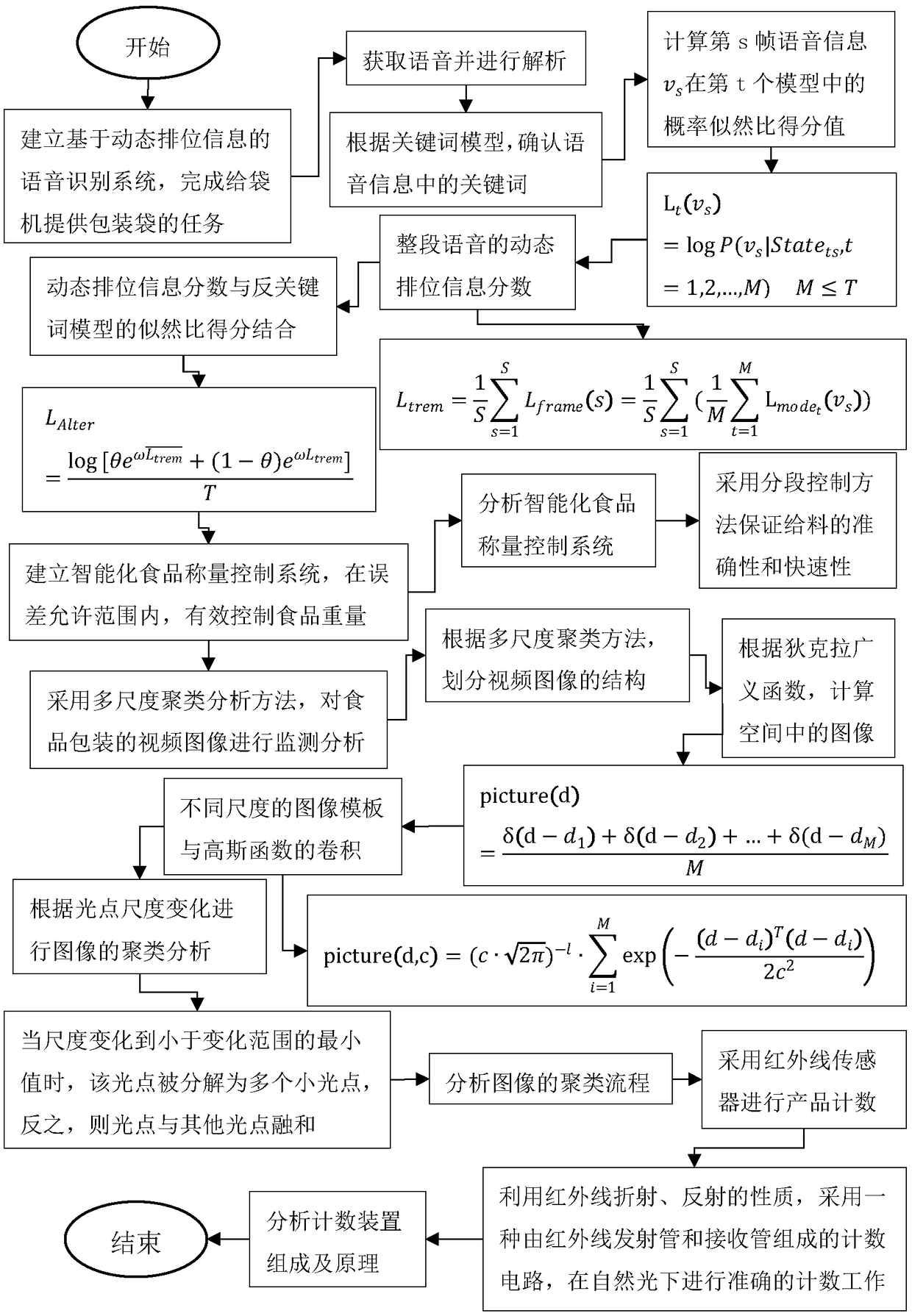

[0060] refer to figure 1 , the method of the present invention comprises the following steps:

[0061] A. Adopt the voice confirmation method based on dynamic ranking information, establish a voice recognition system, and complete the task of providing packaging bags to the bag machine through voice control;

[0062] (1) First obtain a section of speech, use the Viterbi algorithm to analyze the speech, and confirm the keywords in the speech information according to the keyword model in the speech recognition network;

[0063] ① Input a segment of S-frame speech V={v 1 ,v 2 ,...,v S}, this section of speech is recognized as a keyword by the system, and there are T keyword models in the recognition network Mode={mode 1 ,mode 2 ,...,mode T};

[0064] ②The system analyzes the voice information, and each frame of voice information corresponds to a state of the keyword model, and the state sequence of the keyword model is determined by its internal state arrangement;

[0065...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com