An anti-overturning fire fighting robot

A fire-fighting robot and anti-overturning technology, applied in chemical instruments and methods, household refrigeration devices, separation methods, etc., can solve problems such as limited contact area, insufficient friction force, robot overturning, etc., to reduce smoke concentration and improve stability , the effect of preventing high temperature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

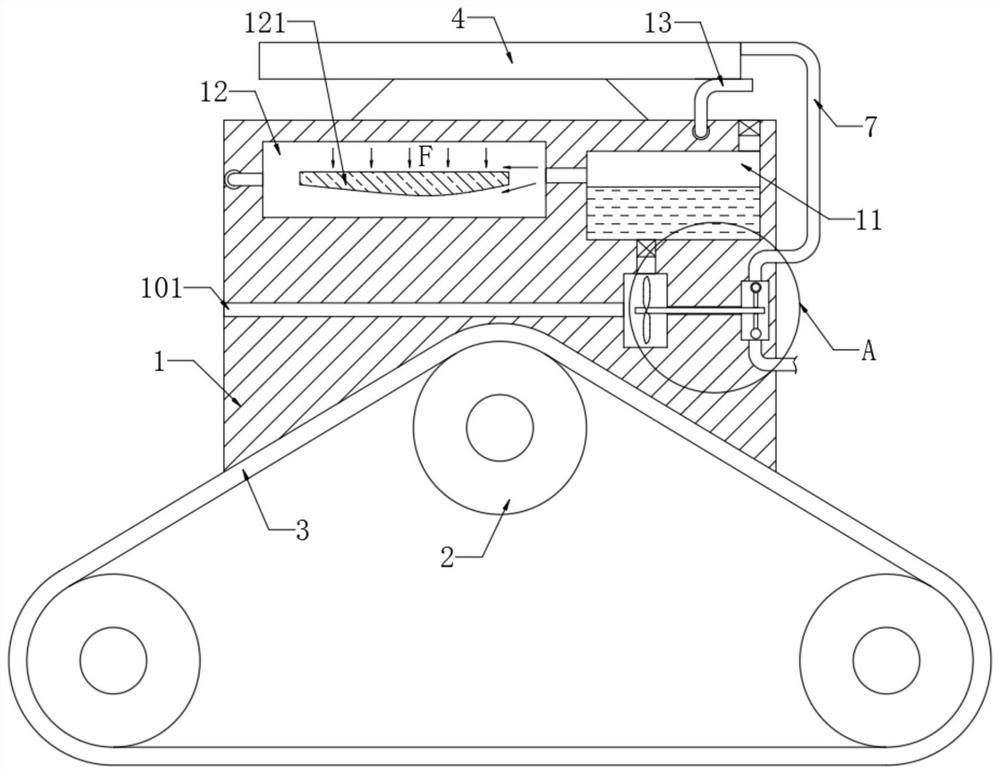

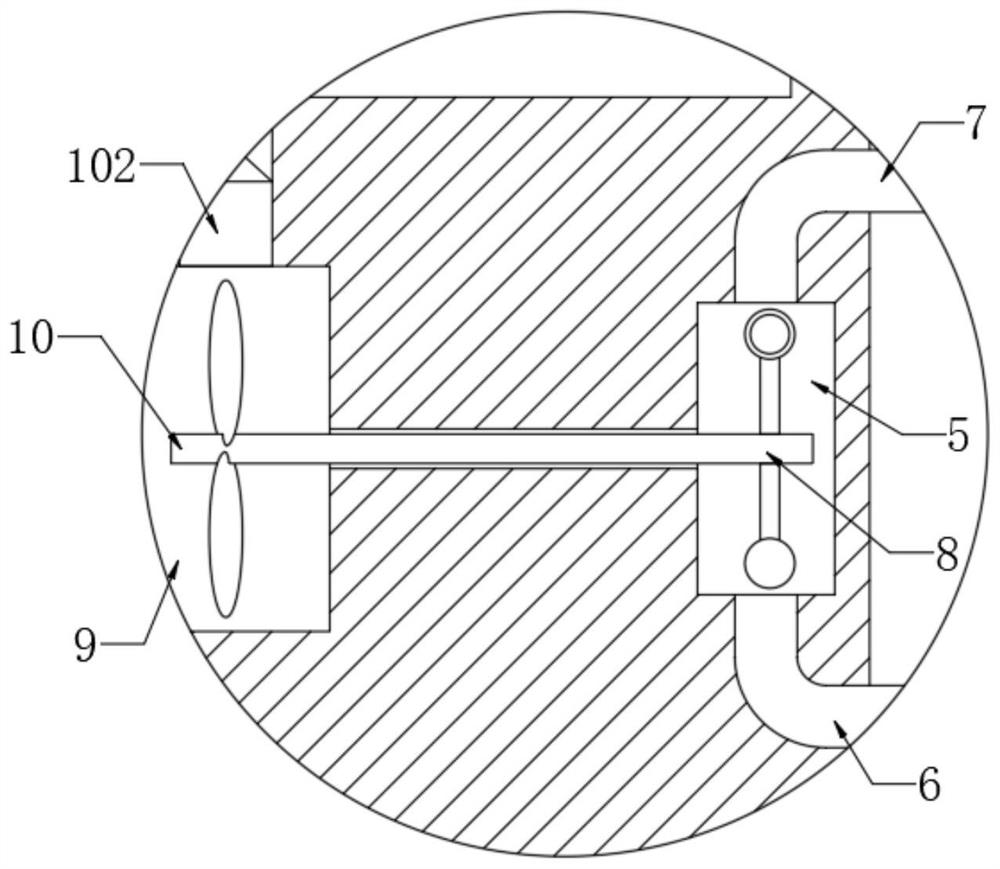

[0022] Refer Figure 1-2 A anti-tilt fire robot, including the vehicle body 1, and the two side walls of the vehicle body 1 are mounted with a plurality of tracks 2, and the plurality of tracks 2 are mounted on the same side, and the upper end of the vehicle body 1 is attached. The tube 4, the sidewall of the vehicle body 1 is opened, and the inner bottom portion of the water flow groove 5 is respectively provided with the inner top portion, respectively, and the water pipe 7 is connected to the air supply pipe 7, and the side of the vehicle body 1 is connected. The wall opens a venting groove 12, and the inner wall of the venting groove 12 is fixedly connected to the airfoil plate 121. The flow line sidewall of the airfoil 121 is close to the inner bottom portion of the venting groove 12, and there is a fixed connection with the venting tank 12 on the side wall of the nozzle 4. The paste of the ventilation tube 13, and the extra gas end of the air pipe 13 away from the water end o...

Embodiment 2

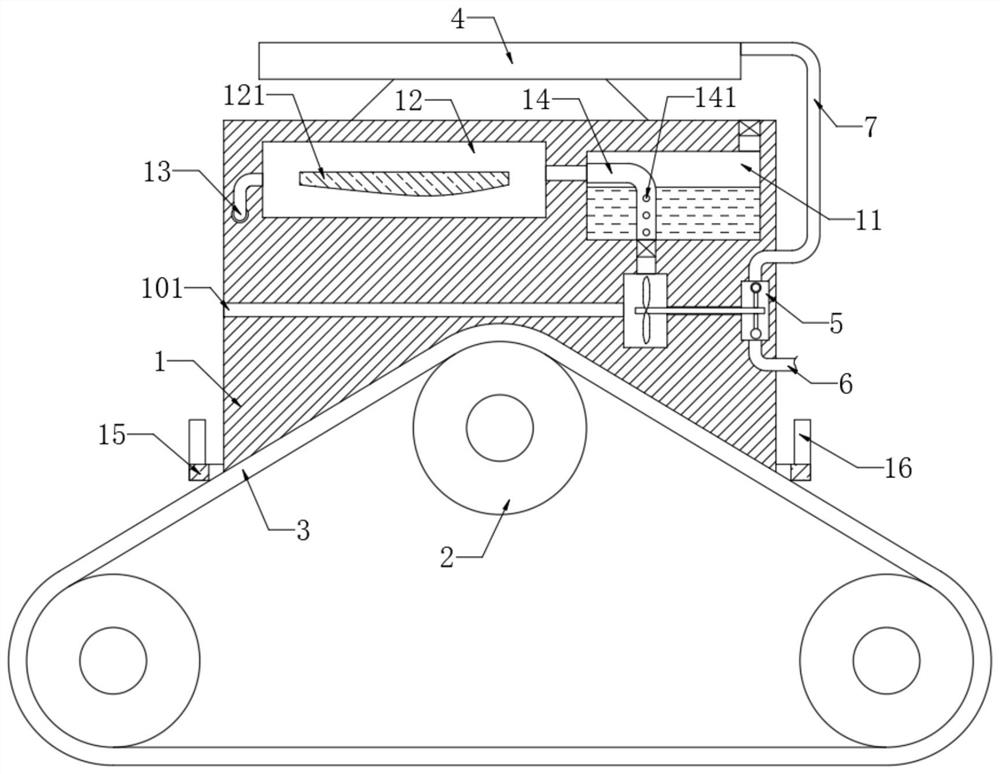

[0029] Refer Figure 3-4 Unlike the embodiment, the outer wall of the vehicle body 1 is fixedly connected to the annular tube 15, and the air pipe 13 is in communication with the annular tube 15, and there is a plurality of nozzles 16, the water storage tank thereof, and the water storage tank is provided on the annular tube 15. 11 There is a bending pipe 14, and the bending pipe 14 communicates with the unidirectional air hole 102, and a plurality of through holes 141 are opened. It should be noted that the aperture 141 is small, and the through hole 141 is at a lower portion of the bending pipe 14, and it is possible to ensure that the through hole 141 is always located below the liquid floor of the water storage tank 11. Further, in the present embodiment, the injection port above the water storage tank 11 is in the open state, and the air pressure in the reservoir 11 can be balanced in the water storage tank 11, and when the air flow occurs in the eluator 14, the water in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com