Rivet feeding device and method

A feeding device and rivet technology, which is applied in the field of self-piercing riveting equipment, can solve problems such as not being able to meet the rivet feeding, and achieve the effect of avoiding automatic falling off, avoiding movement and angle deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

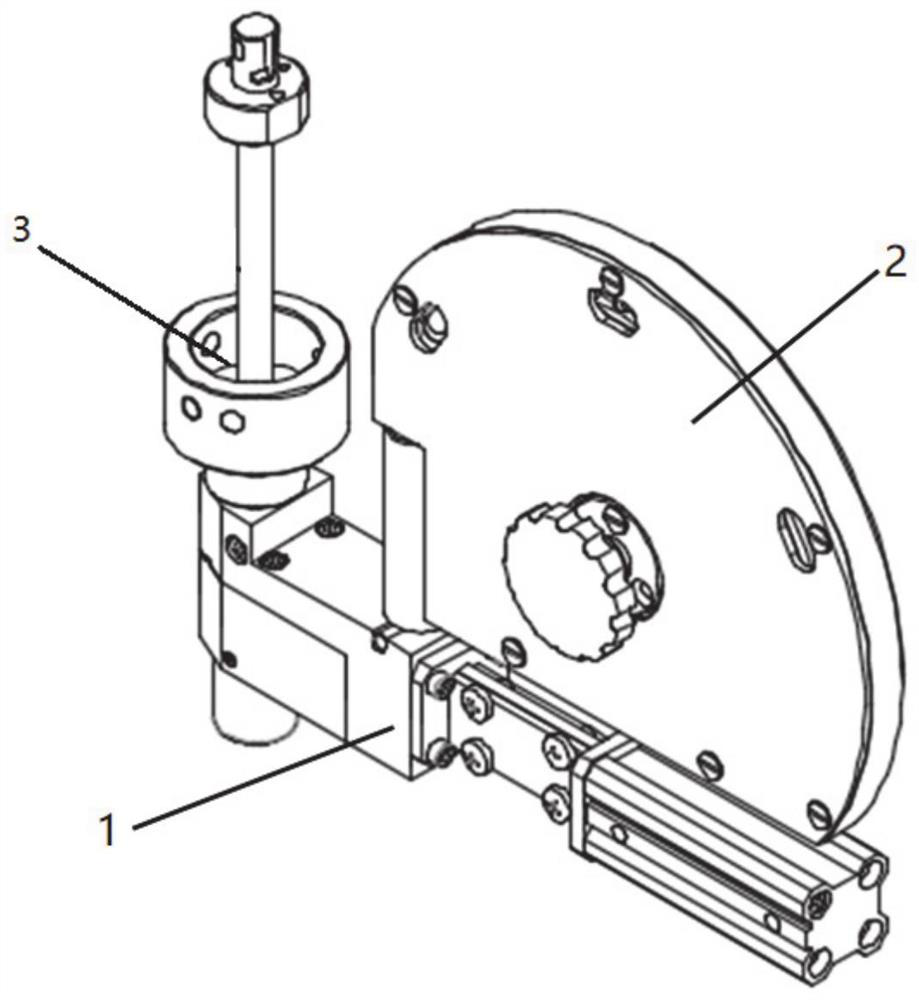

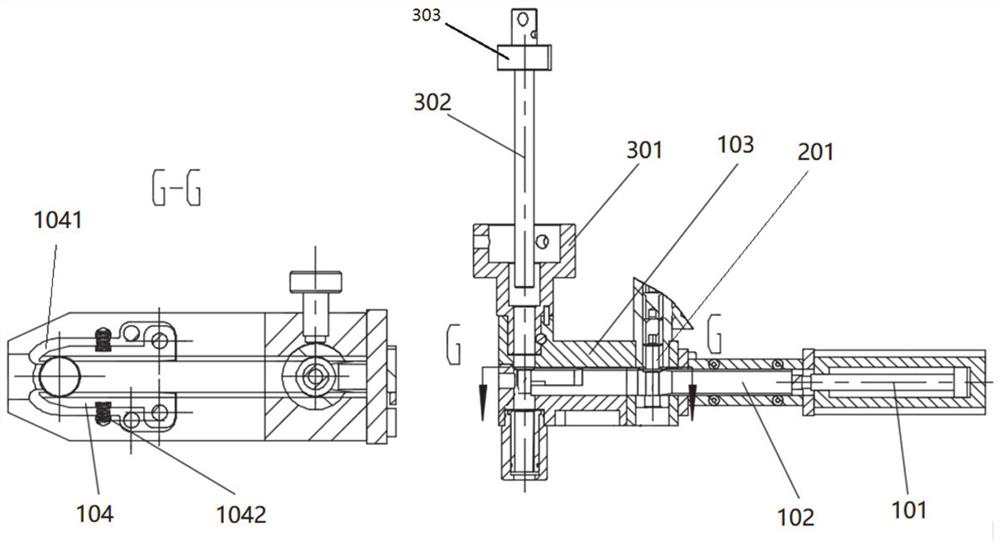

[0039] A rivet feeding device, comprising: a rivet gun 1, a hopper 2 and a feeding unit 3; the rivet gun 1 includes a T-shaped body 103 and a cylinder 101 connected thereto; the T-shaped body 103 is provided with a corresponding T type material channel; the push rod 102 of the cylinder 101 is socketed in the material channel at the end of the T-shaped body 103 vertical bar away from the horizontal bar; the material bin 2 is arranged in an arch shape, and the material bin 2 is fixed on On the vertical rod of the rivet gun 1; one end of the arched silo is provided with a silo port 201, and the silo port 201 communicates with the material channel; the feeding unit 3 includes a connecting sleeve 301 provided with a through hole A cylindrical punch 302 is arranged in the through hole of the connecting sleeve 301 ; the feeding unit 3 is socketed on one end of the horizontal rod of the T-shaped body 103 through the connecting sleeve 301 .

[0040] The cross-section of the push rod 10...

Embodiment 2

[0050] Embodiment 2 of the present invention discloses a rivet feeding method, which adopts the rivet feeding device described in Embodiment 1, and specifically includes the following steps:

[0051] Load a certain number of rivets into the silo 2 so that the rivets are closely arranged linearly in the silo;

[0052] Install the silo 2 on the rivet gun to realize the communication between the silo port 201 and the material channel;

[0053] The push rod 102 of the cylinder pushes the rivet from the initial position to the working position. In the working position, under the action of the spring 1042, the chuck 104 can hold the rivet and wait for the punch to move down for riveting;

[0054] Further, the push rod 102 can only push one rivet in one displacement, and after the push rod 102 is retracted, the rear rivets move down sequentially, waiting for the next cycle;

[0055] The rivets in the material storage channel in the material storage bin of the present invention are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com