Hoisting device of horizontal modality test

A hanging device and modal test technology, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc., can solve unsolvable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

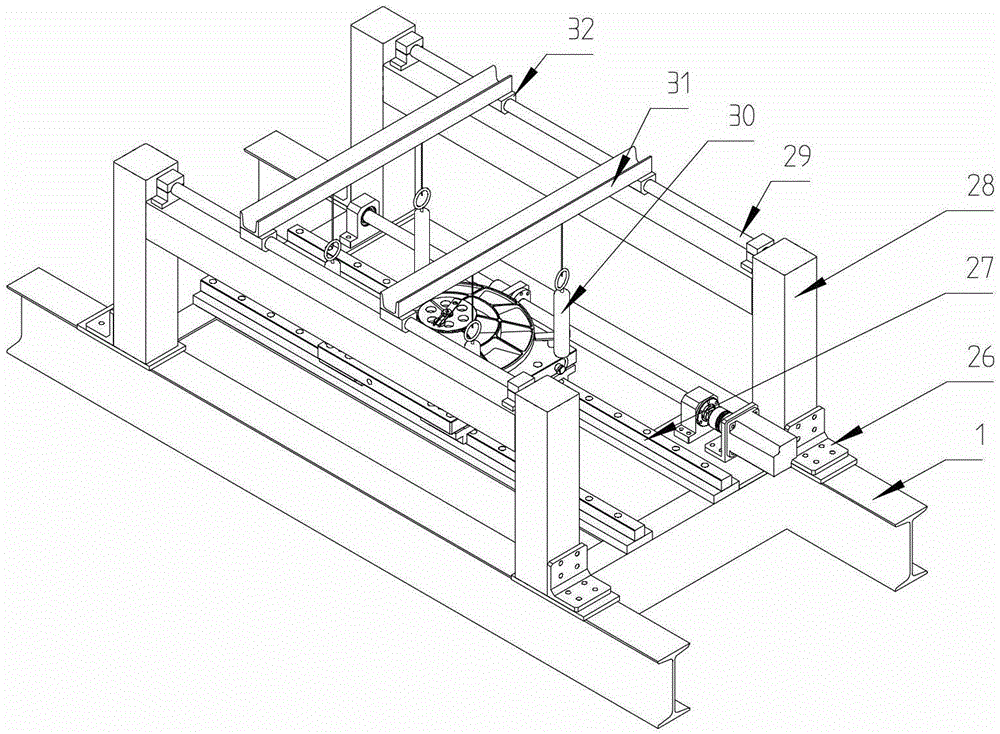

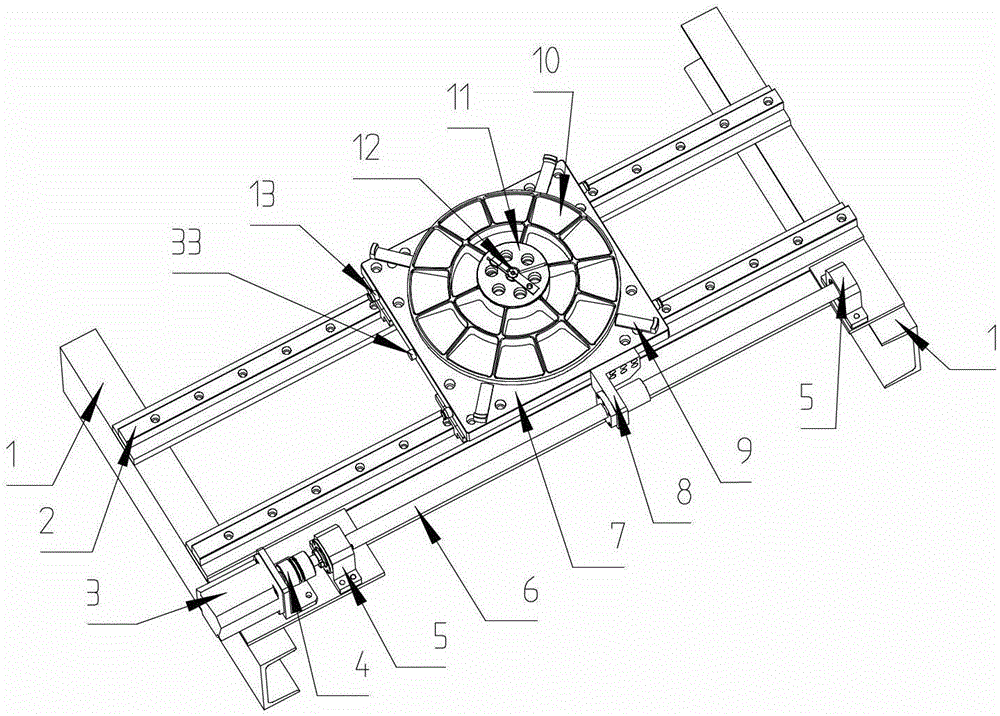

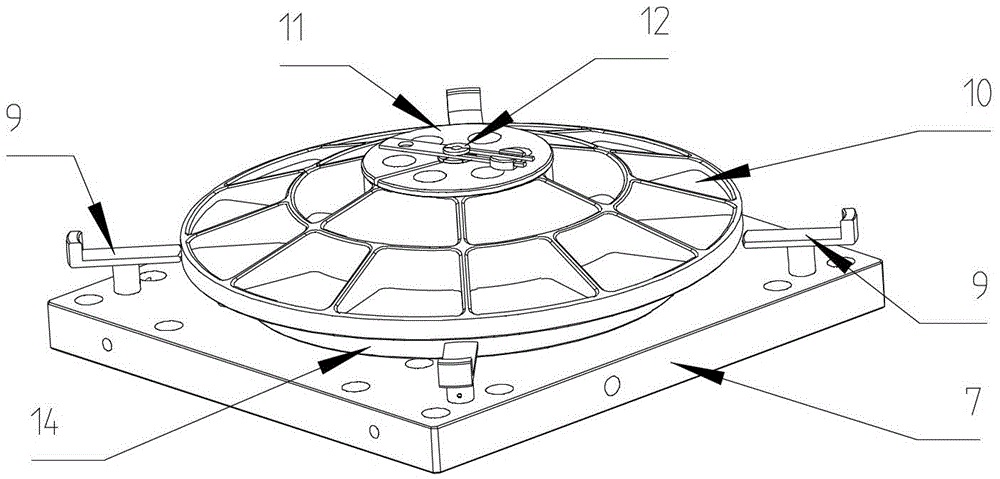

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] refer to Figure 1~Figure 7 , a horizontal modal test hanger, comprising a modal test air flotation hanger 27 and a modal test weight-reducing device, the modal test air flotation hanger 27 includes an air flotation ring mounting plate 7, close to the opening 9 off, air flotation ring 14, air flotation plate 10, clamping rope assembly, load-reducing hanging column 13, laser displacement sensor 33, linear guide rail 2, host base 1, wherein, the clamping rope assembly includes clamping rope chassis 11, threading Rope half cone card 12, locking card 25, locking deck 24. The modal test weight reducing device includes a linear slide rail 29 , a slider 32 , a spring scale 30 , a channel steel 31 , a bracket 28 and a connecting piece 26 . The modal test weight reducing device is installed above the modal test hanging device 27 through a bracket 28 .

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com