Three-direction variable type heavy machine tool foundation model box controllable in boundary condition

A foundation model and heavy-duty machine tool technology, which is applied in basic structure engineering, basic structure testing, construction, etc., can solve the problems of inability to change its size, difficulty in adjusting soil pressure, low utilization rate, etc., and achieves convenient locking and saving. Time, easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

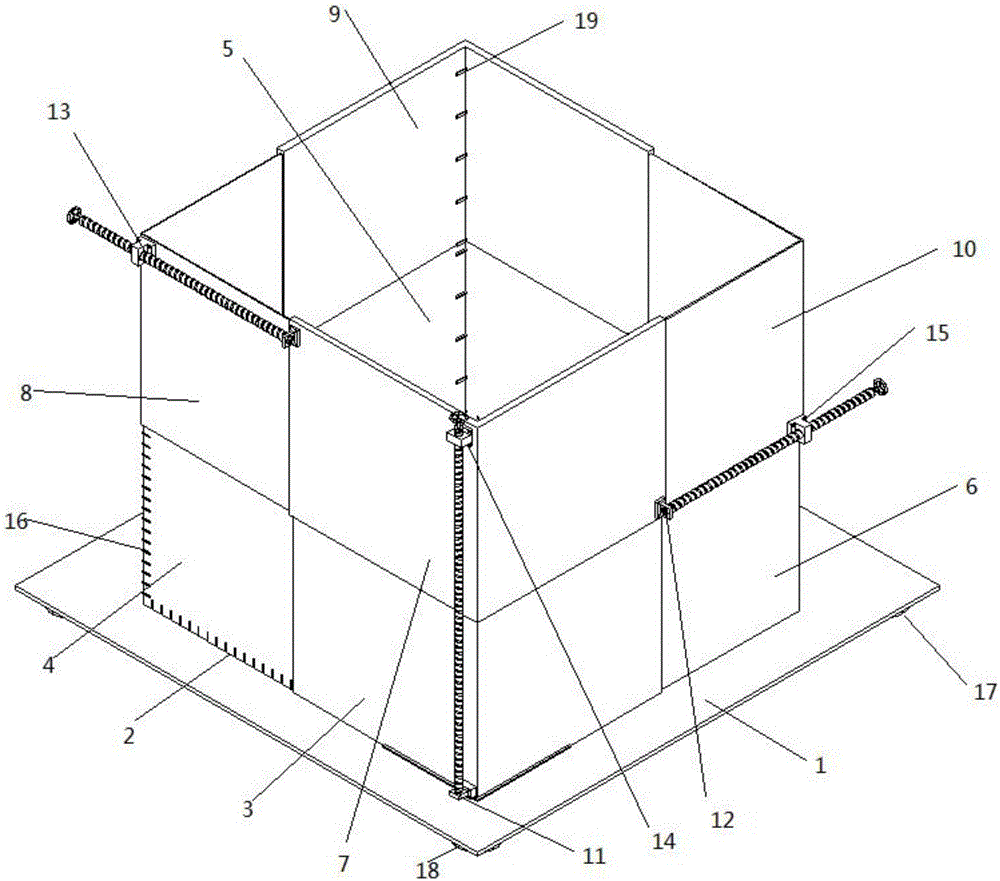

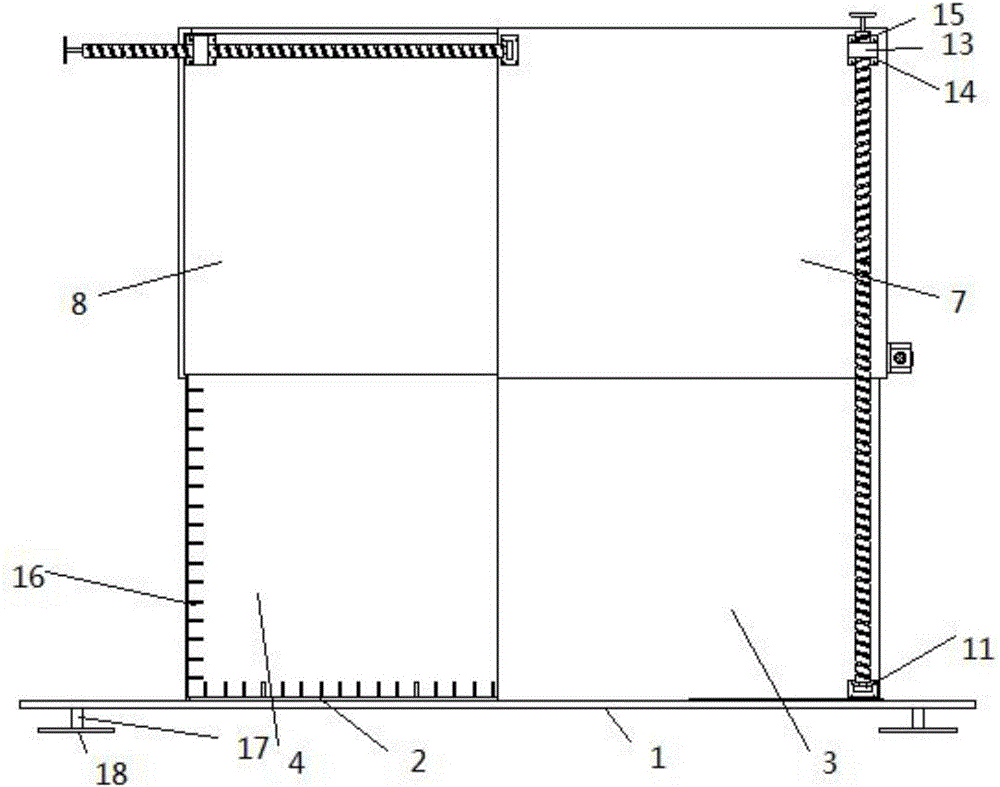

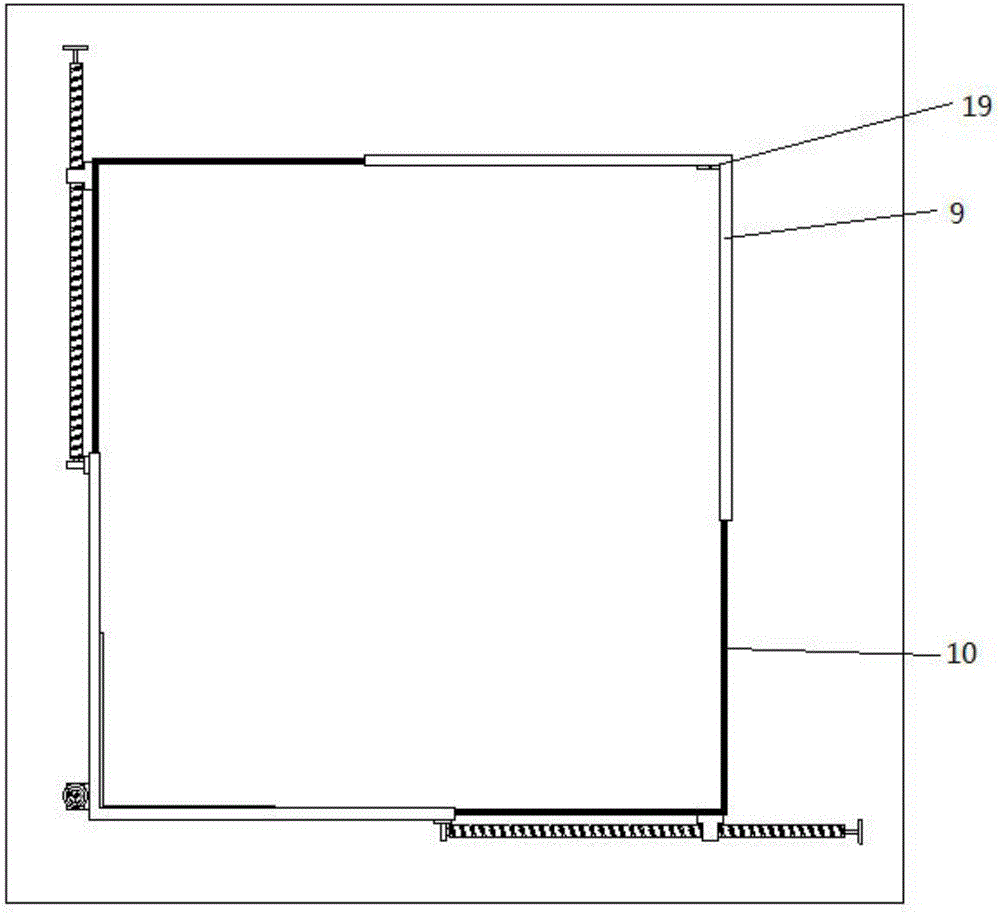

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-Figure 10 Shown is a three-way variable model box device. In the figure, bottom plate 1, leak-proof strip 2, lower baffle A3, lower baffle B4, lower baffle C5, lower baffle D6, upper baffle E7, upper baffle F8, upper baffle G9, upper baffle H10, bearing base 11, bearing 12, ball screw lifter 13, bolt groove 14, bolt 15, scale 16, displacement sensor 17, horizontal knob 18, pressure sensor 19. The leak-proof strip 2 just covers the gap between the bottom plate and each baffle; the lower baffle A3, the lower baffle B4, the lower baffle C5, and the lower baffle D6 are horizontally inserted into each other; the upper baffle E7, the upper baffle F8, the upper baffle The baffle G9 and the upper baffle H10 are inserted into each other horizontally and vertically inserted into the lower baffle A3, the lower baffle B4, the lower baffle C5, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com