Ladder-free heat conduction LED lamp likely to dissipate heat

An LED lamp and ladder technology, applied in the field of lighting, can solve the problems of increased processing cost, insufficient heat conduction, and adverse effects on the heat dissipation process, and achieve the effect of increasing lamp life, excellent heat dissipation effect, and avoiding rapid failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

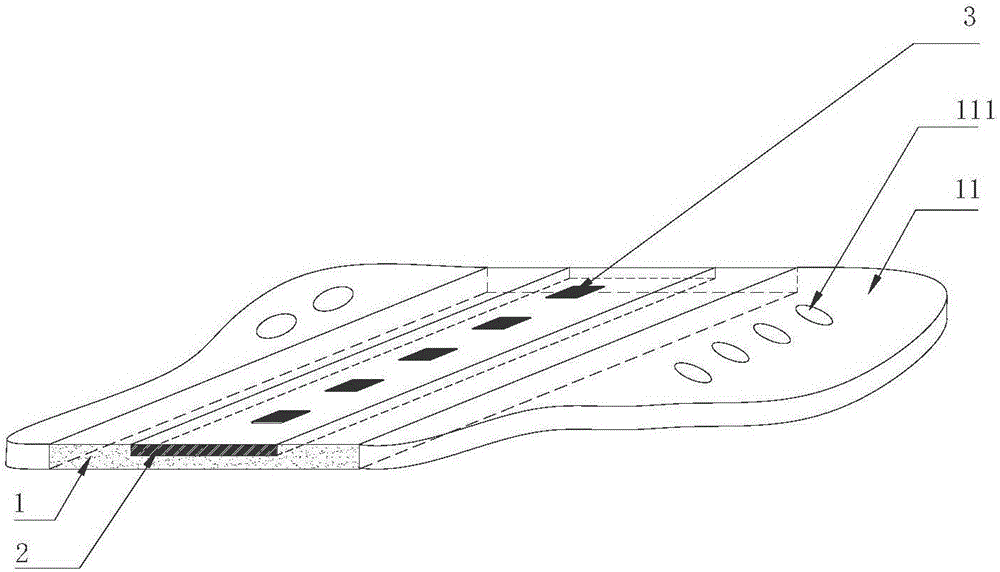

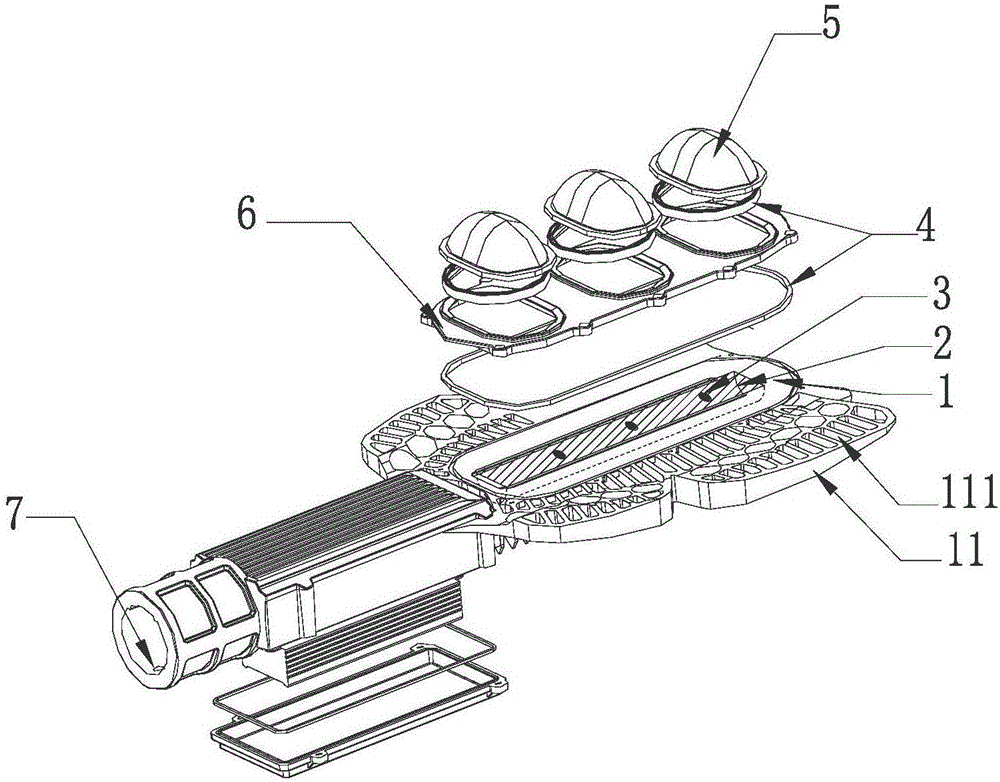

[0032] Embodiment 1 shows a typical application of an LED lamp without stepwise heat conduction and easy heat dissipation of the present invention. figure 2 It is a schematic diagram of the LED lamp without stepwise heat conduction and easy to dissipate heat in Example 1.

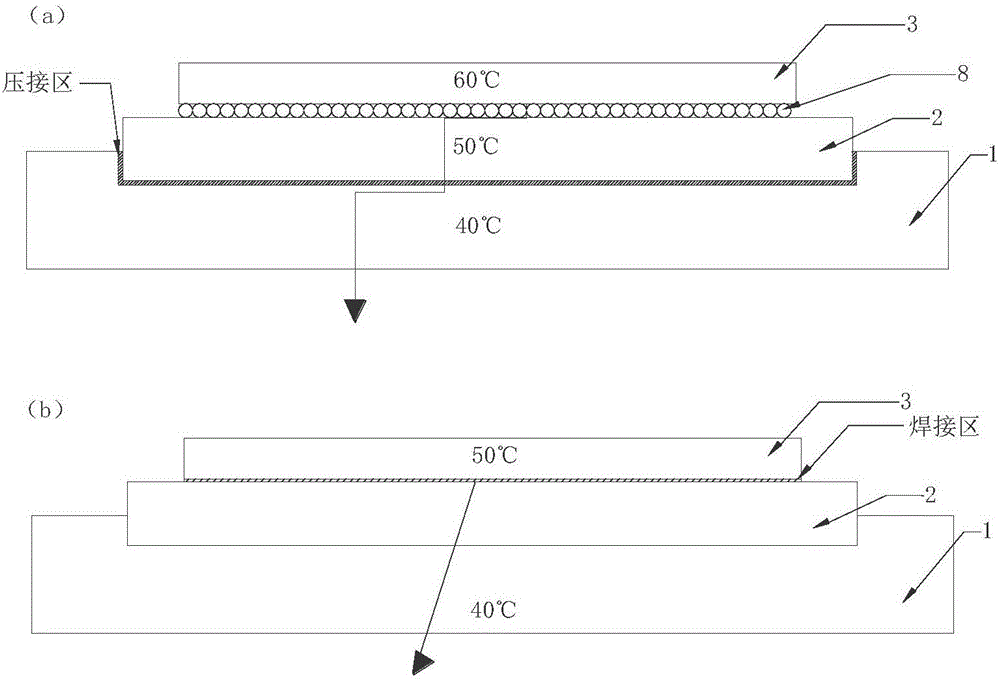

[0033] as attached figure 2 As shown, a non-step heat-conducting and easy-to-dissipate LED lamp in this embodiment includes an aluminum lamp holder 1, a heat sink 2 and an LED heat source 3, the aluminum lamp holder 1 and the heat sink 2 are an integrated structure, and the LED heat source 3 and the LED heat source 3 are integrated. The heat sink 2 is in close contact, that is, the LED heat source 3 is installed on the heat sink 2 . In practical applications, installation positions can be pre-set on the surface of the heat sink 2 for the installation of the LED heat source. A common LED heat source is COB lamp beads.

[0034] In this embodiment, the heat sink 2 is made of metal copper. The thermal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com