Foam pump

A foam pump and pump body technology, applied in the field of foam pumps, can solve the problems of poor foaming effect and the inability to change the amount of foam sprayed according to needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

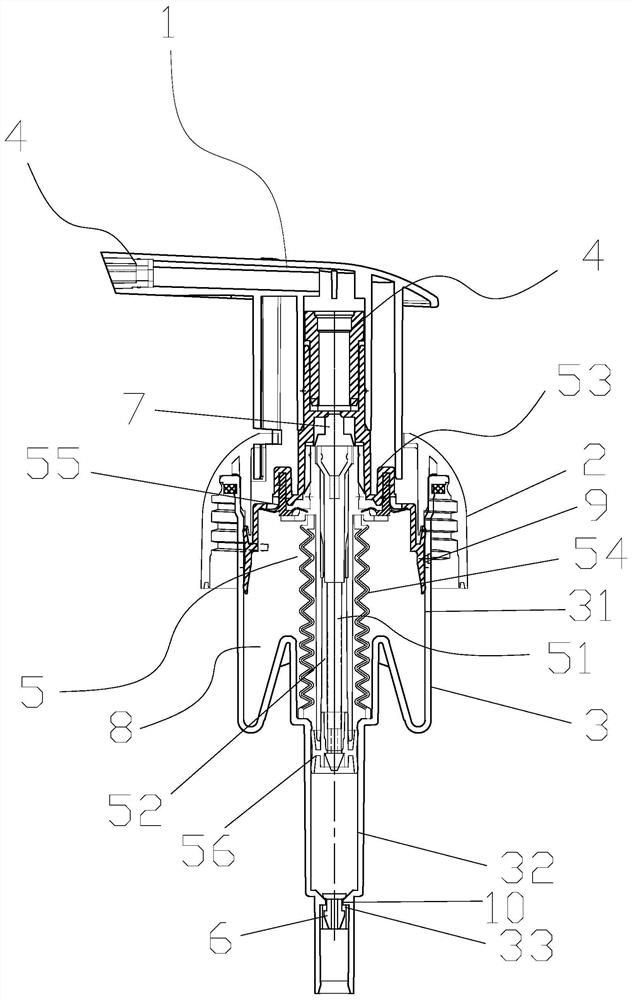

[0064] exist figure 1 , figure 2 In the shown embodiment, a kind of foam pump, all parts of this foam pump all adopt the all-plastic structure that can recover, including:

[0065] Press the pump head 1, which is used to press the operating parts for foaming and foaming;

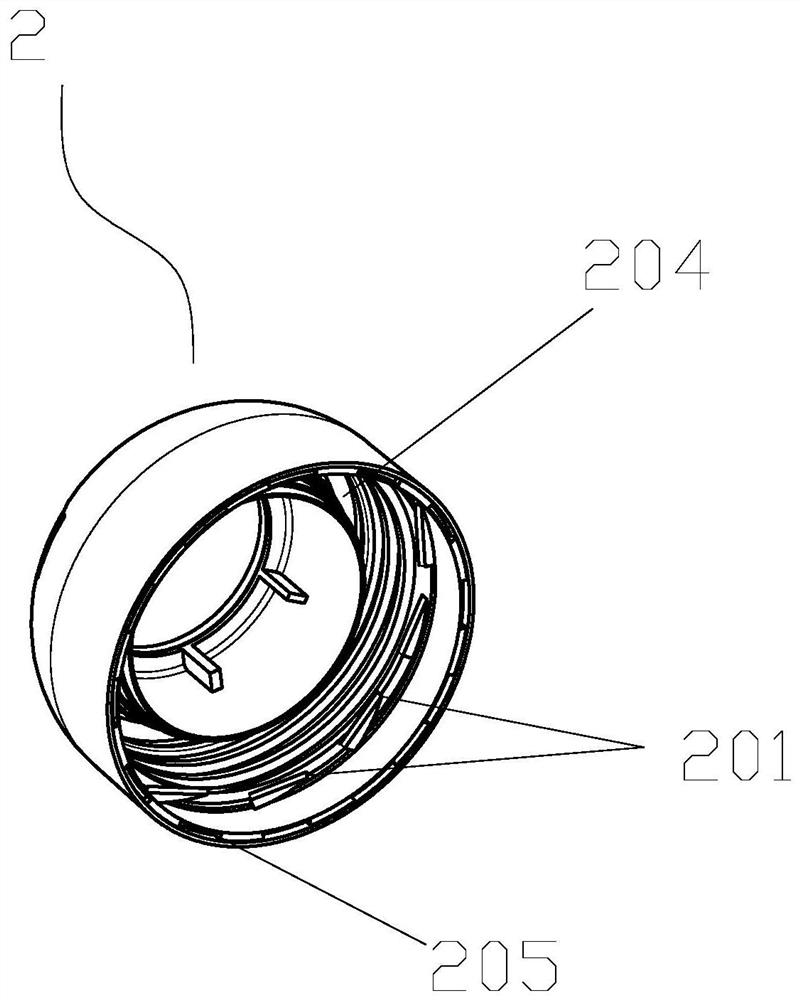

[0066] The screw cap 2 is used to connect the pump body and the liquid container 11 and the connecting parts for positioning and pressing the pump head;

[0067] The pump body 3 is the main part of the foam pump. The pump body 3 is connected with the screw cap 2 by a sealing card. The pump body 3 is integrally provided with a cylinder 31, a hydraulic cylinder 32 and a liquid valve seat 33;

[0068] Foaming component 4, which is arranged inside the pump head 1 for foaming;

[0069] The elastic pressing component 5 is arranged inside the pump body 3 and is linked with the pressing pump head 1, and is used to compress the gas in the cylinder to realize the upper gas and to compress the liquid in the hydraul...

Embodiment 2

[0083] exist Figure 18 In the shown embodiment, a kind of foam pump, its technical scheme is basically the same as that of embodiment 1, the difference is that: in this embodiment, the foaming component is only provided with the initial foaming component, and no foaming foaming component is provided. components.

Embodiment 3

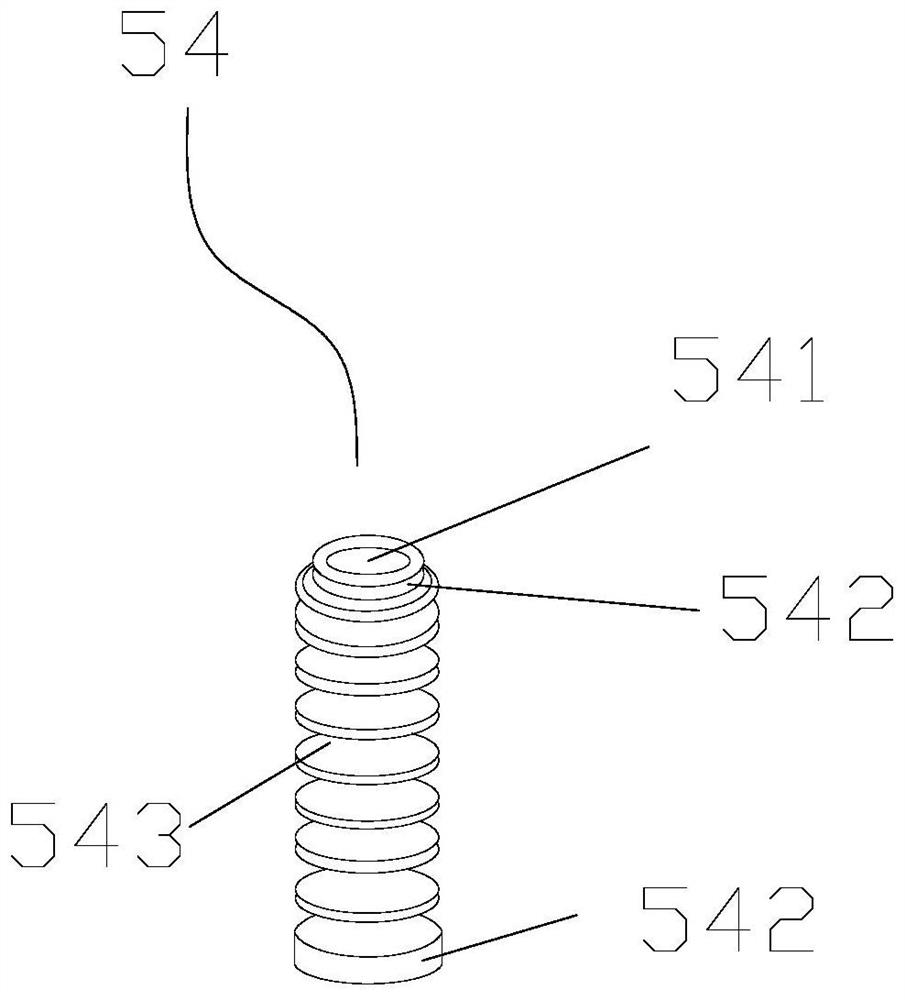

[0085] exist Figure 19 In the shown embodiment, a kind of foam pump, its technical scheme is basically the same as embodiment 1, the difference is: the diameter of the all-plastic closed spring and the structure of the pump body are different, in this embodiment, both can change The diameter of the spring also changes the volume of the cylinder inside the pump body to meet the requirements of large-capacity spraying. The throughput of the pump body can be designed from 0.1cc to 1.6cc to meet different spraying volume requirements. Of course , although the diameter of the spring and the volume of the pump body have been changed, the requirement of controlling the amount of bubbles can still be achieved by varying the size of the extrusion force during the process of squeezing and spraying bubbles.

[0086] like Figure 20 , Figure 21 Shown, the foam pump in the above-mentioned embodiment, concrete operation is as follows:

[0087] like Figure 20 As shown, rotate and pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com