Conveying device for food detection

A conveying device and food detection technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of limited feeding speed, easy to pile up, and inconvenient feeding, so as to reduce labor intensity and improve Detection efficiency, effect of avoiding confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

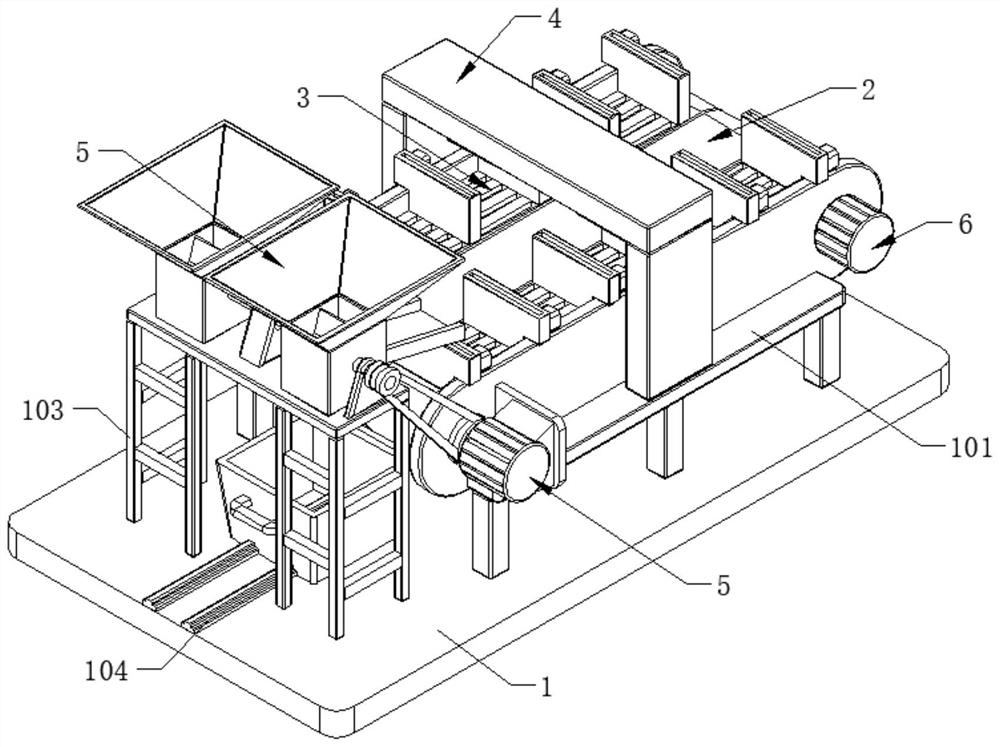

[0035] refer to Figure 1-6 , a conveying device for food detection, comprising a bottom plate 1 and a conveying mechanism 2, a first support frame 101 is connected to the top wall of the bottom plate 1, a protective plate 102 is connected to the top wall of the first support frame 101, and the conveying mechanism 2 is connected to the protective On the inner wall of the plate 102, on the top wall of the first support frame 101, a detection assembly 4 is also connected, and the detection assembly 4 is matched with the conveying mechanism 2. The conveying mechanism 2 includes a first conveyor belt 201, a second conveyor belt 202 and a third conveyor belt 203. A conveyor belt 201 and the second conveyor belt 202 have the same conveying direction and are staggered with each other. The second conveyor belt 202 is opposite to the conveying direction of the first conveyor belt 201. The first conveyor belt 201 and the second conveyor belt 202 are connected with a conveying assembly 3 ...

Embodiment 2

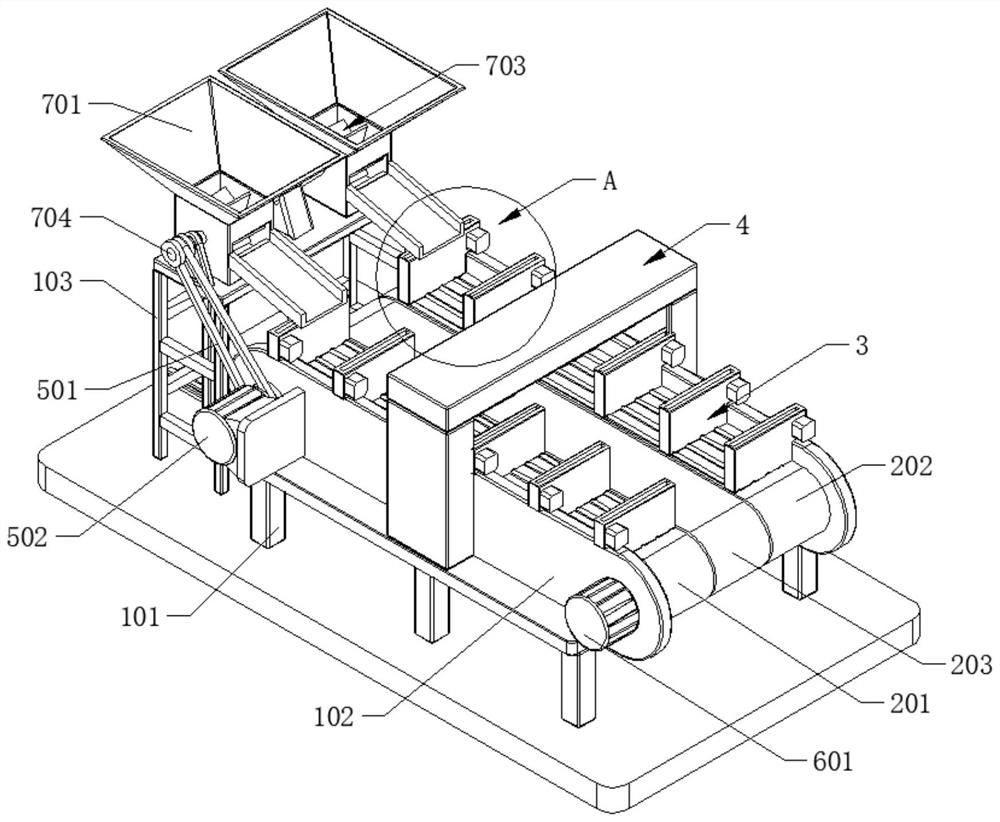

[0040] refer to Figure 1-8 , a conveying device for food detection, which is basically the same as in Embodiment 1, and further, a conveying device for food detection, comprising a base plate 1 and a conveying mechanism 2, the top wall of the base plate 1 is connected with a first support frame 101, The top wall of the first support frame 101 is connected with a protective plate 102, the conveying mechanism 2 is connected on the inner wall of the protective plate 102, and the detection assembly 4 is also connected on the top wall of the first support frame 101, and the detection assembly 4 matches the conveying mechanism 2, The conveying mechanism 2 comprises a first conveyor belt 201, a second conveyor belt 202 and a third conveyor belt 203. The first conveyor belt 201 and the second conveyor belt 202 have the same conveying direction and are interlaced with each other. The second conveyor belt 202 is opposite to the first conveyor belt 201 conveying direction. The first con...

Embodiment 3

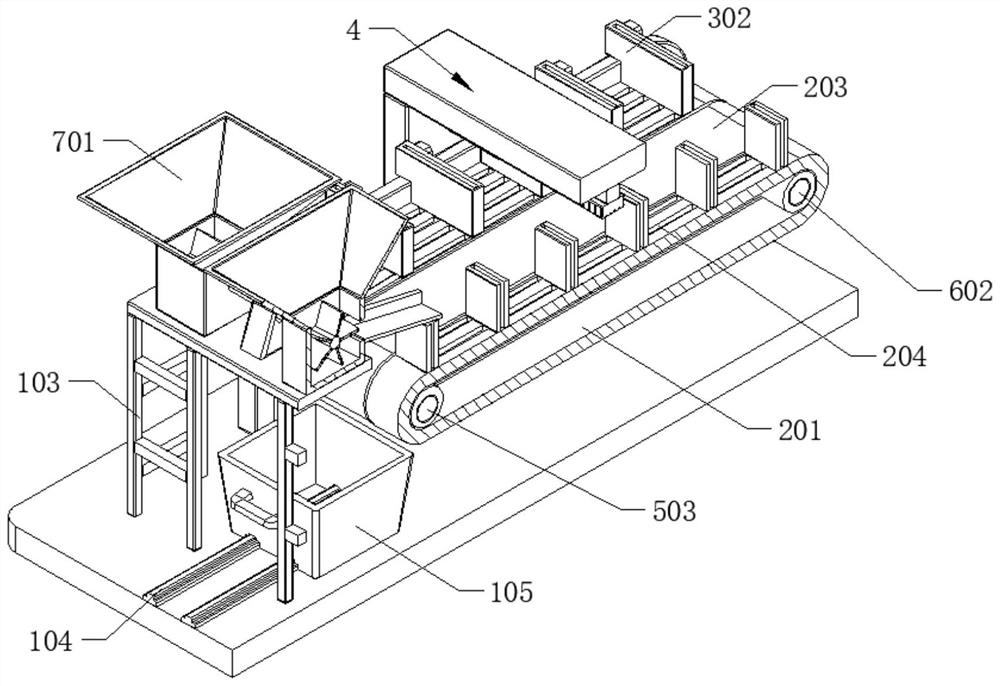

[0048] refer to Figure 1-5 , a conveying device for food detection, which is basically the same as that of Embodiment 1, furthermore, the feeding assembly 7 includes a feeding funnel 701 and a discharging tray 702, and the feeding funnel 701 is connected to the top wall of the second support frame 103, One end of the discharge tray 702 is connected to the outer wall of the feeding funnel 701 , and the other end is matched with the conveying mechanism 2 .

[0049] The inside of the feeding funnel 701 is also provided with a shifting assembly 703, the shifting assembly 703 includes a third rotating shaft 704 and a shifting plate 705, the third rotating shaft 704 is connected to the inner wall of the feeding funnel 701, and one end of the third rotating shaft 704 Through the feed funnel 701 and connected to the output end of the first drive motor 502 through the first belt 501, the material shifting plate 705 is connected on the outer wall of the third rotating shaft 704, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com