Feeding conveying system of automatic shrimp peeling machine

A technology of conveying system and feeding conveyor belt, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve the problems of low shrimp peeling efficiency, low efficiency, and low automation of manual feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] As a preferred embodiment of the present application, this embodiment discloses a feeding and conveying system for an automatic shrimp peeling machine. Shrimp feeding, the efficiency of shrimp feeding is slow, the degree of automation of the shrimp peeling machine is low, and the efficiency of peeling shrimp is low.

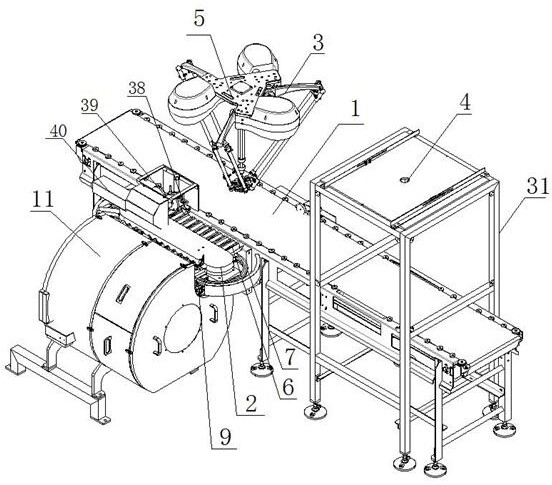

[0086] Depend on Figure 1-4 Shown, a kind of feeding conveying system of automatic shrimp peeling machine comprises feeding tray 2, and described feeding tray 2 is provided with some shrimp grooves 6, and described feeding tray is provided with feed inlet 8 and outlet. The feed port 9, the feed conveying system of this embodiment also includes a feed conveyor belt 1 and a manipulator 3. Refer to the attached figure 1 and 2 , compared with the prior art, the present embodiment changes the vertical structure of the feeding tray 2 in the existing shrimp peeling machine body into a horizontal structure, that is, an annular surface 7 formed by the movement ...

Embodiment 2

[0101] As another preferred embodiment of the present application, this embodiment provides a technical implementation of the feeding system of an automatic shrimp peeling machine. The feeding arrangement is very different, which leads to the problems of low degree of automation and low efficiency of shrimp peeling. This application is based on the original shrimp peeling machine equipment, making minor improvements to the feeding tray, and increasing the feeding of the manipulator, so as to improve the efficiency of peeling shrimp, improve the feeding arrangement efficiency of raw shrimp, and improve the efficiency of peeling shrimp. degree of automation of the machine. The technical solutions are as follows:

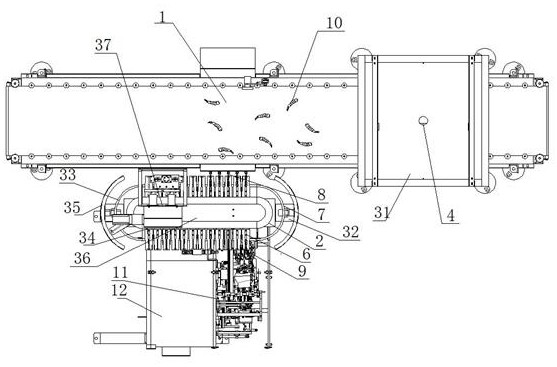

[0102] like Figure 7 shown, ( Figure 7 The manipulator is not shown in the figure 1 The manipulator arrangement structure diagram in ) is a feeding system of an automatic shrimp peeling machine, including a feeding tray 2, which is provided with a number of shrim...

Embodiment 3

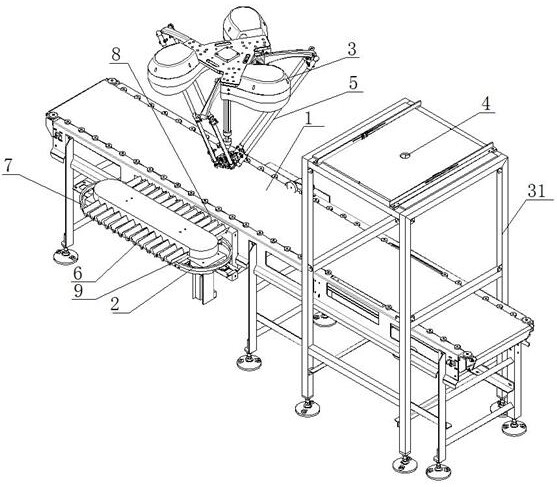

[0112] As another preferred embodiment of the present application, refer to the accompanying Figure 8 , the present embodiment provides a technical solution for the feeding and conveying method of an automatic shrimp peeling machine. The purpose of this technical solution is to solve the problems of poor automation, low feeding arrangement efficiency, Food safety and low efficiency of shrimp peeling. The technical solution adopts a manipulator for feeding, which can effectively realize the automatic feeding arrangement of raw shrimp, and can effectively improve the feeding arrangement efficiency of raw shrimp and the shrimp peeling efficiency of the shrimp peeling machine.

[0113] The technical solutions disclosed in this embodiment are as follows:

[0114] A feed conveying method for an automatic shrimp peeling machine, comprising the following steps:

[0115] Conveyor belt feeding step: the raw shrimp 10 is transported by the feeding conveyor belt 1 to the visual collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com