FPC appearance inspection machine and its double-sided inspection mechanism and inspection method

A visual inspection and double-sided technology, applied in the field of inspection, can solve problems such as low efficiency and poor effect, and achieve the effect of improving stability, improving efficiency, and stabilizing installation and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

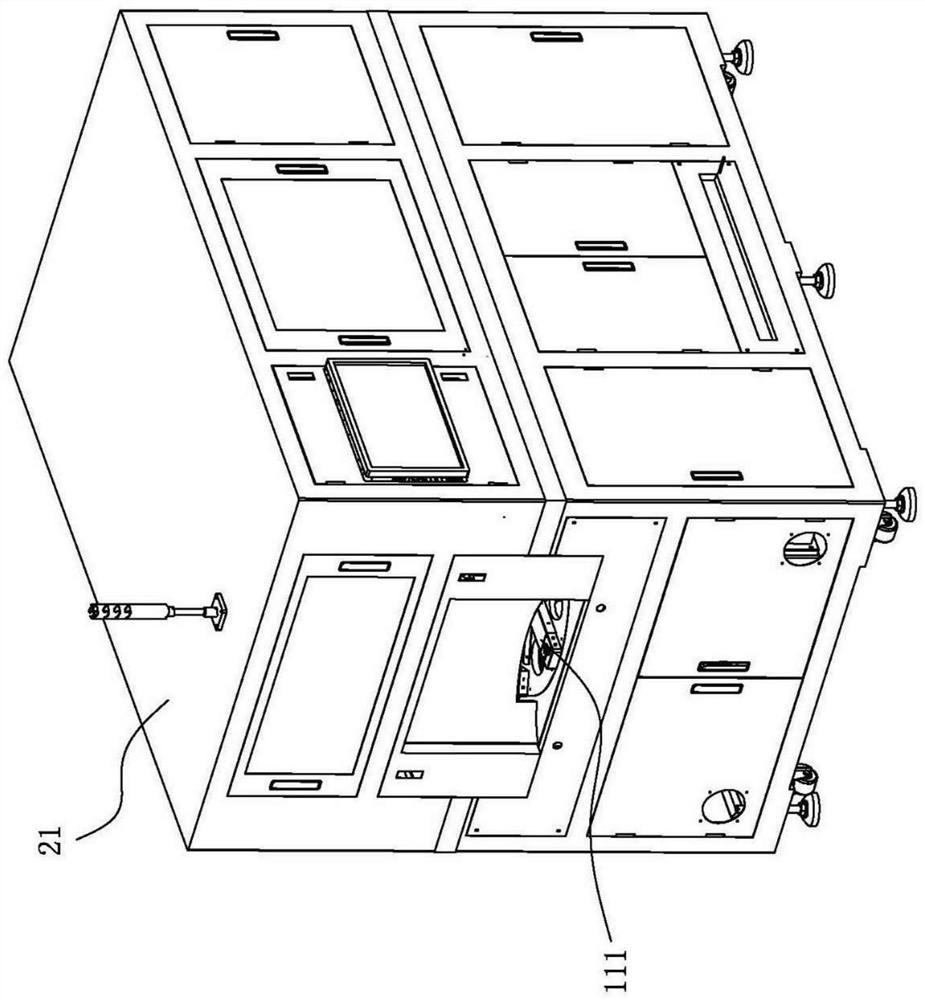

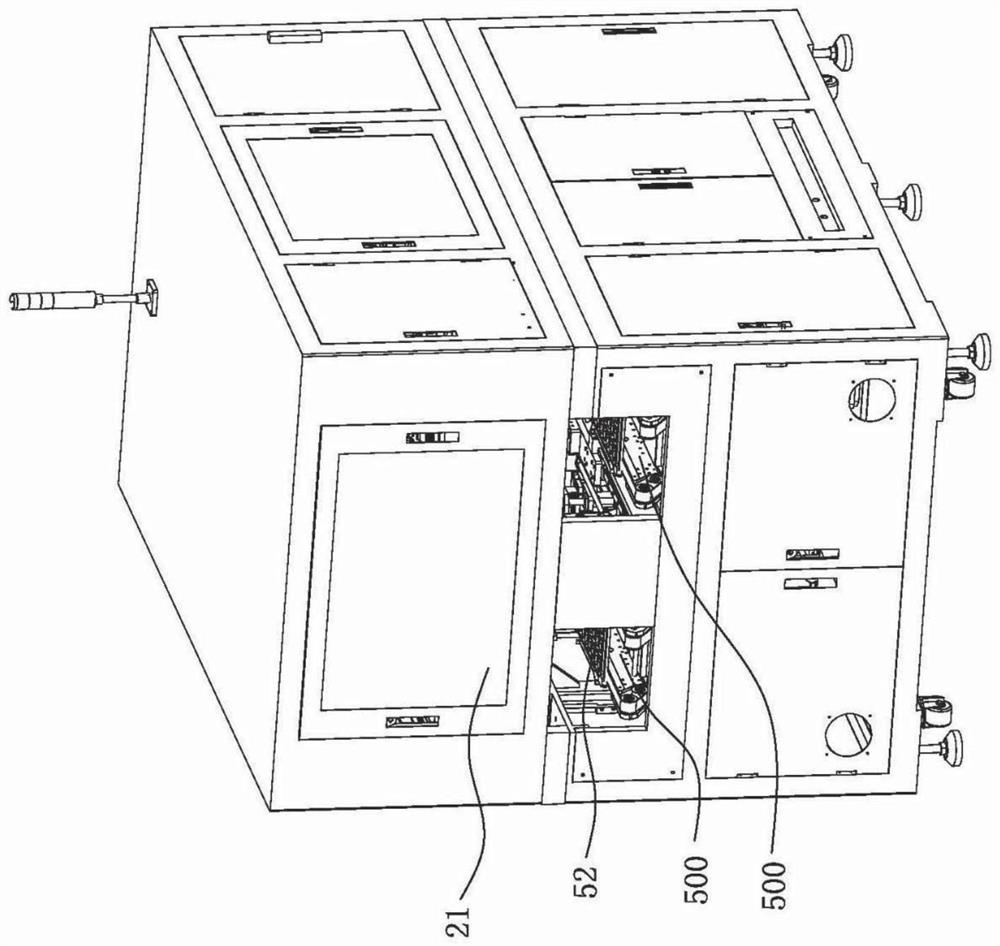

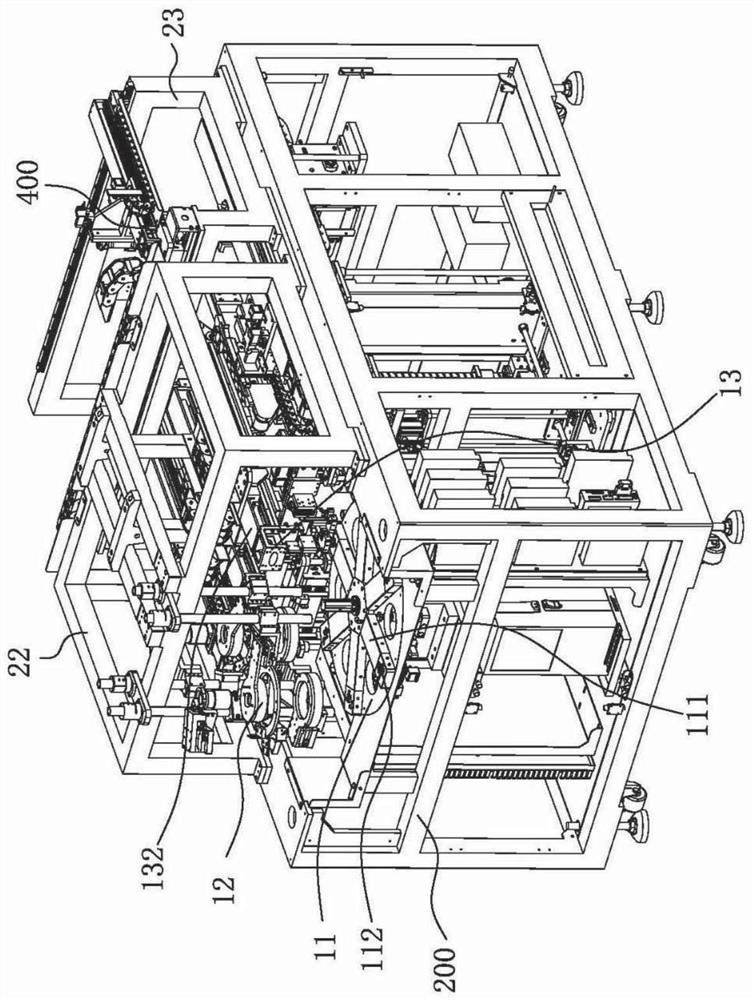

[0056] Such as Figure 1 to Figure 4 An embodiment of the shown FPC visual inspection machine includes a frame 200, a control mainframe (not shown) placed on the frame 200, and an FPC double-sided visual inspection mechanism electrically connected to the control mainframe (not shown in the figure). marked), the frame 200 is provided with a shell 21 to protect the internal mechanisms of the FPC visual inspection machine; the FPC double-sided visual inspection mechanism includes a turntable 11 and an inspection system (not marked in the figure), wherein the turntable 11 can rotate intermittently, and the turntable 11 is distributed with a plurality of stations 111, and each station 111 is respectively provided with a first carrier 112 for placing workpieces (not shown in the figure), and the first carrier 112 is transferred sequentially on the plurality of stations 111. The position 111 includes a front inspection station and a back inspection waiting station; the inspection sys...

Embodiment 2

[0069] A FPC visual inspection method as shown in Figure 14 is applicable to the FPC visual inspection machine in Example 1, including steps:

[0070] Workpiece loading, loading the workpiece onto the first carrier 112 at the station 111 of the turntable 11;

[0071] Double-sided inspection, synchronously collect front or back images of workpieces placed at different inspection stations 111 and send them to the control host;

[0072] The workpiece is temporarily stored, and the temporary storage and handling mechanism 300 receives the workpiece after double-sided inspection, and moves it to the temporary storage and unloading position;

[0073] Sorting and loading, the sorting and loading mechanism 400 sorts and grabs the workpieces at the temporary storage and unloading position according to the signal fed back by the control host, and loads them into the corresponding tray 600;

[0074] Tray discharge: the tray supply mechanism 500 transfers the sorted and loaded trays 600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com