Discharge mechanism of powder metallurgy press

A technology of powder metallurgy and discharge mechanism, applied in the direction of presses, manufacturing tools, etc., can solve problems such as chaos and disorder, difficulty in accurately grasping materials, and the impact of unloading, so as to increase the frequency of grasping, reduce labor intensity, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

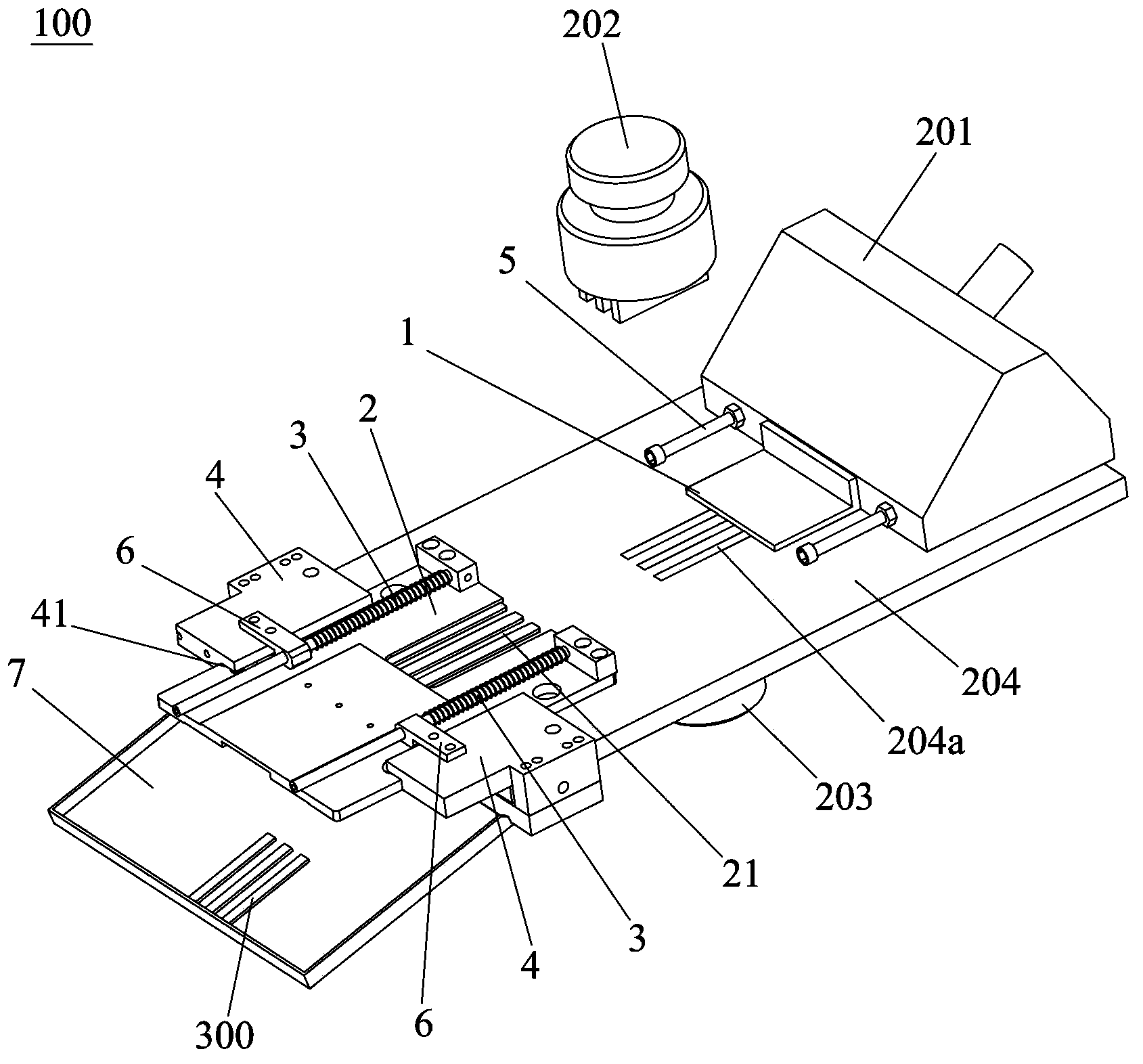

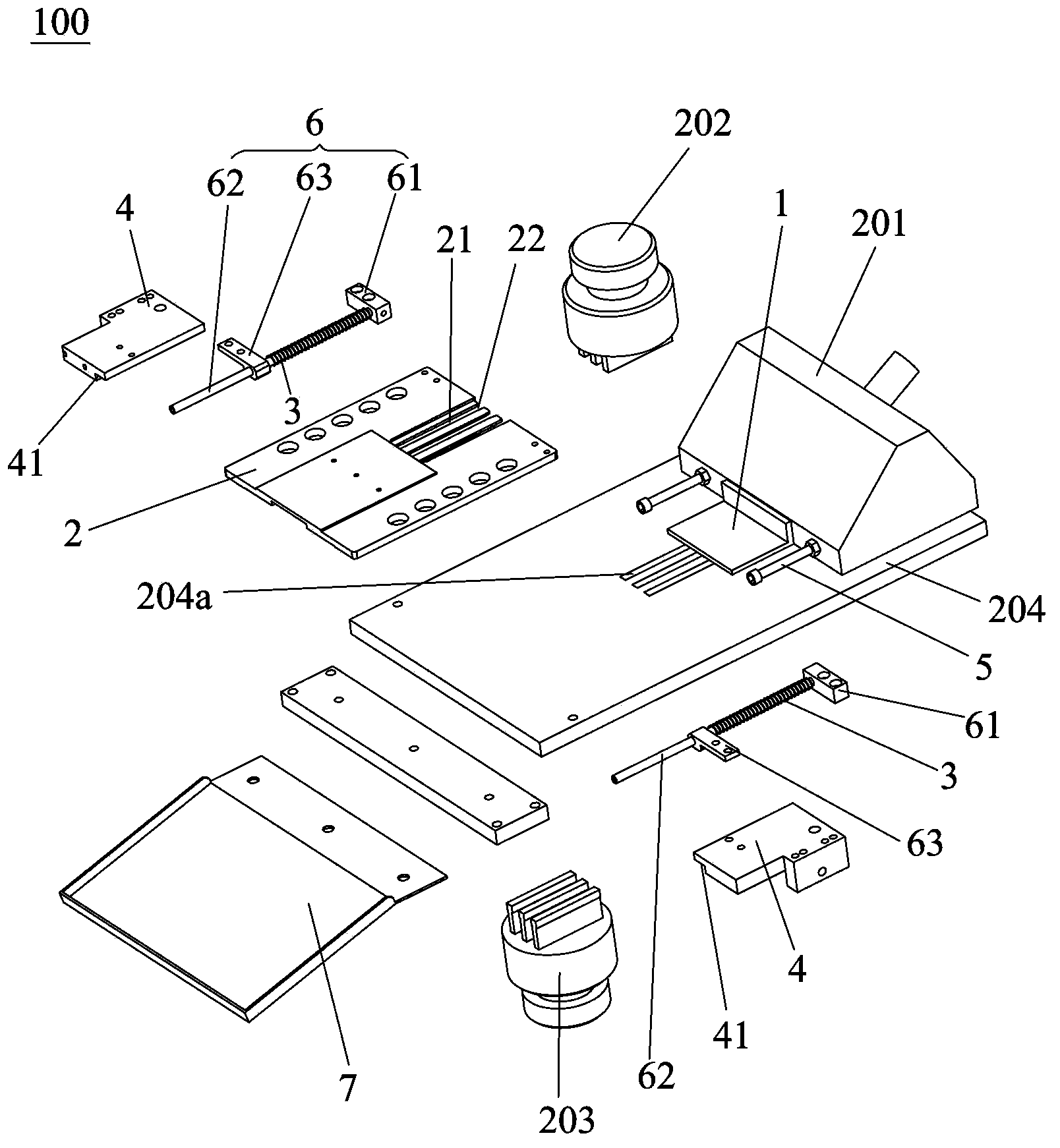

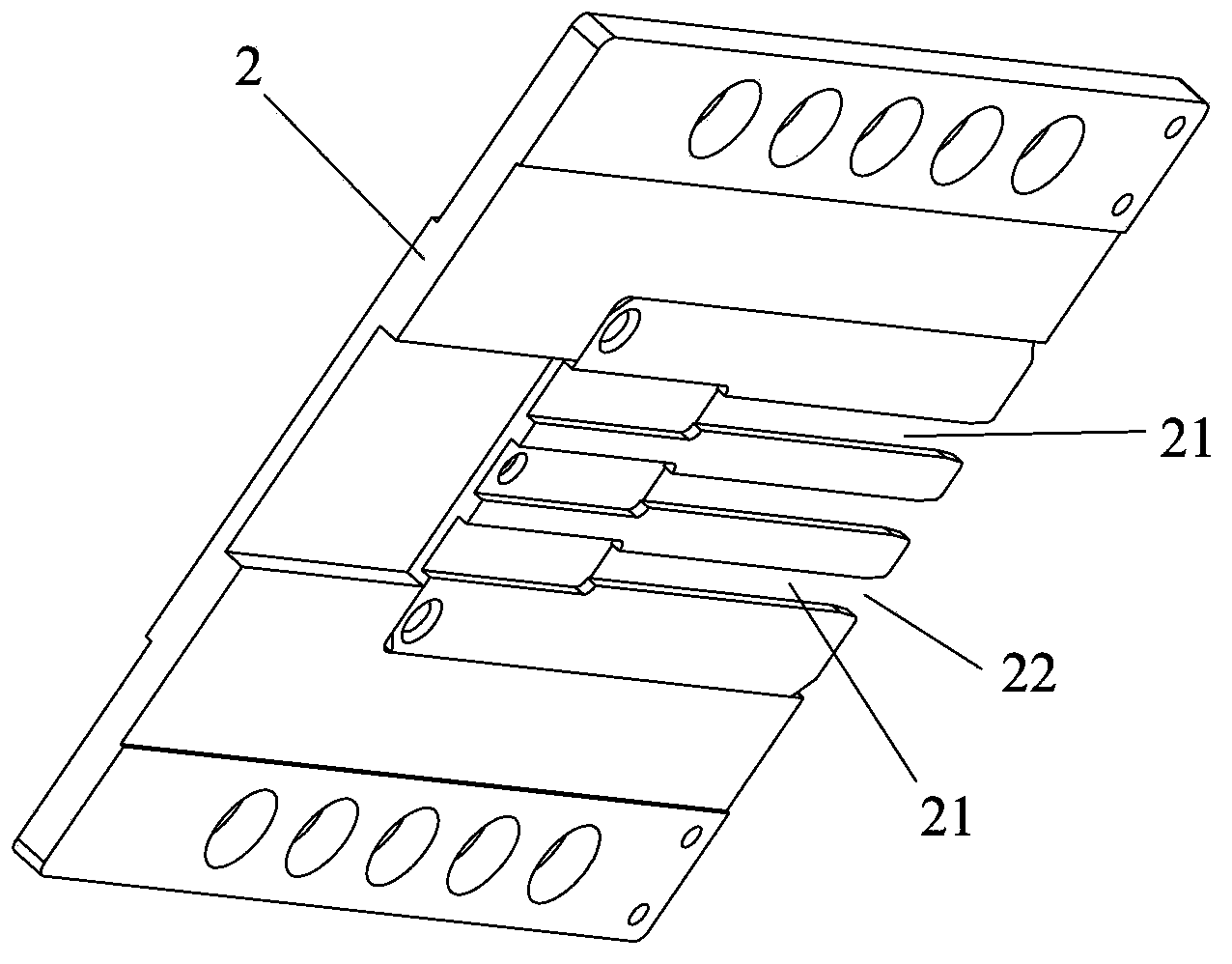

[0020] Such as figure 1 as shown, figure 1 The discharge mechanism 100 of the powder metallurgy press of the present invention is shown. The powder metallurgy press includes a cavity main body 201, an upper pressure head 202, a lower pressure head 203 and a stripping plate 204. The stripping plate 204 is provided with three passages through The upper and lower surfaces of a rectangular mold cavity 204a, the upper and lower pressing heads 202, 203 are respectively located on both sides of the stripper plate 204 and can compress metal powder into a workpiece 300 in the mold cavity 204a. The lower pressing head 203 can push the workpiece 300 upwards, so that the bottom surface of the workpiece 300 is 0.2 mm higher than the surface of the stripper plate 204; the cavity main body 201 is slidingly arranged on the stripper plate 204 Above, the discharge mechanism 100 of the powder metallurgy press includes a forward pusher 1, a discharge box 2, a pair of elastic elements 3, a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com