Special take-up device frame for high-voltage test wire

A high-voltage test and wire take-up technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as waste of energy, cable entanglement, and inconvenient take-up, so as to achieve convenient and safe work and prevent Electric shock, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

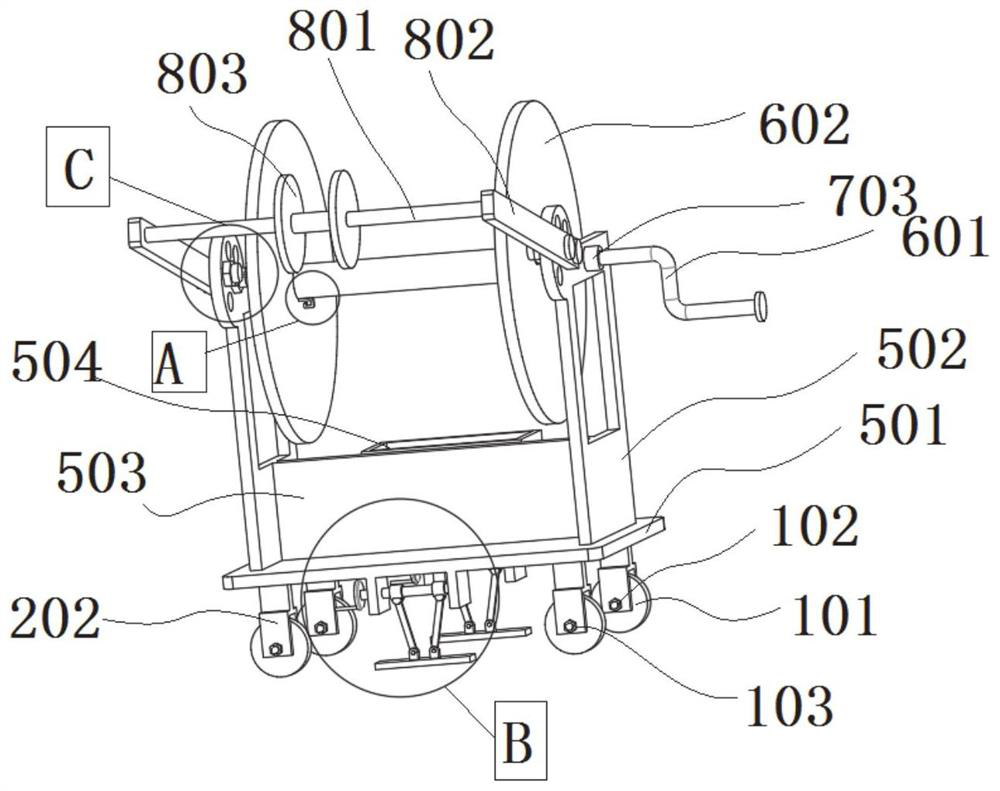

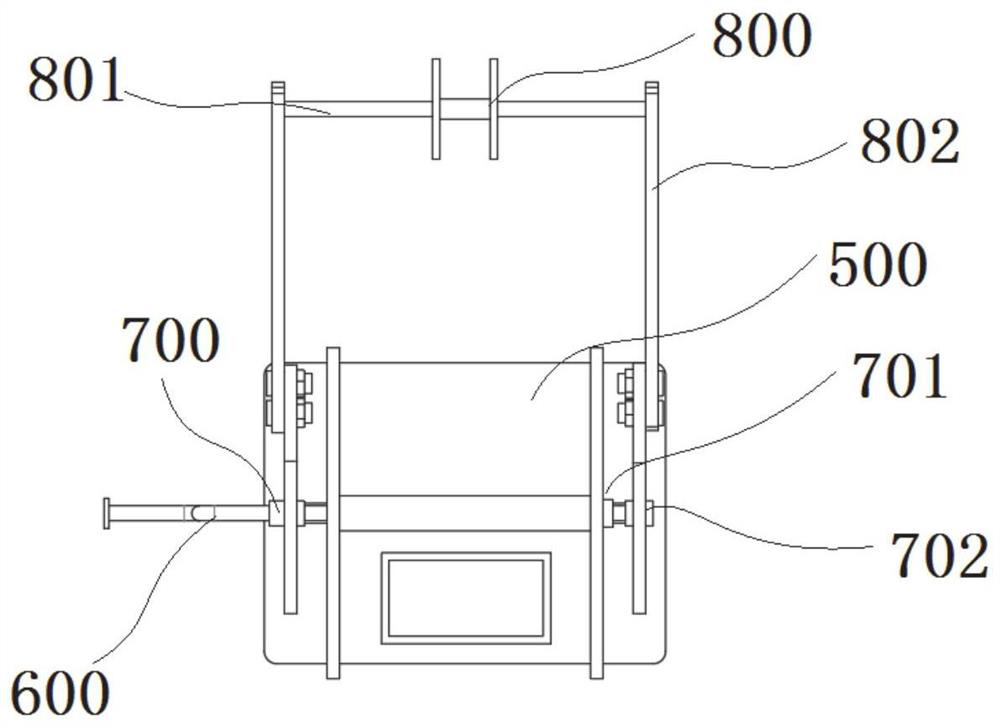

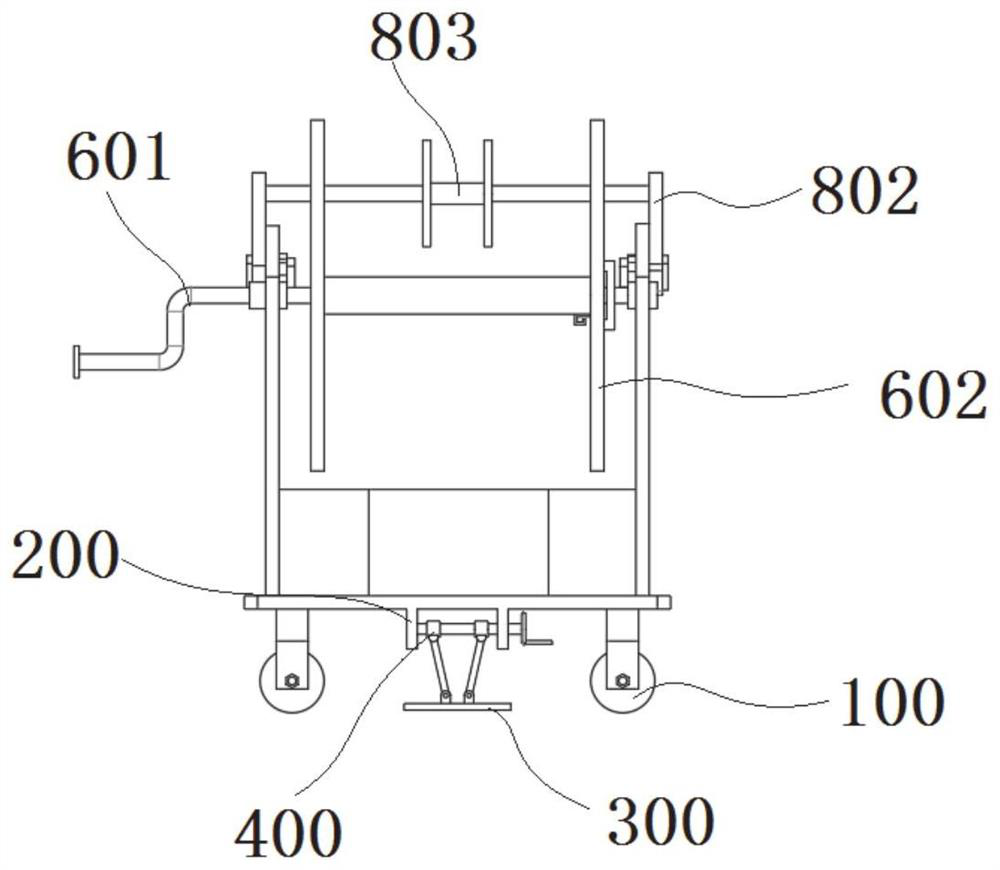

[0032] see Figure 1-6 As shown, the present invention is a special wire take-up rack for high-voltage test lines, including a moving device 100, a fixing device 200, a stabilizing device 300, a connecting device 400, a supporting device 500, a wire taking-up device 600, a limiting device 700 and a preventing device 800, The moving device 100 includes a wheel shaft 102, the fixing device 200 includes a protruding block 201, a shaft plate 202, and a rotating shaft 203, a shaft hole is provided on one side of the shaft plate 202, the wheel shaft 102 is rotatably matched with the shaft hole, and the stabilizing device 300 includes a connecting rod 303, The connection device 400 includes a slider 401 and a rotating block 402. The slider 401 is arranged on the outer surface of the rotating shaft 203. One side surface of the rotating block 402 is welded to one end of the rotating shaft 203. The supporting device 500 includes a bottom plate 501, a supporting plate 502, and a protrudin...

Embodiment 2

[0042] see Figure 1-6 As shown, the present invention is a special wire take-up frame for high-voltage test line. Its use method and working principle are as follows: when working, the device is moved to the set working position through the wheel 101, and after reaching the working position, the handle 403 is rotated to drive the rotation The block 402 moves to make the rotating shaft 203 rotate. The rotating shaft 203 is provided with threads, and the slider 401 is also provided with threads. By rotating, the sliding block 401 and the rotating shaft 203 move in the opposite direction, thereby driving the connecting rod 303 to move. 303 drives the compression plate 301 to compress, so that the device is fixed on the ground and does not shake during work. Then one end of the cable is wound on the hook 603, and the cable is arranged on the movable pulley 803 to prevent it from being entangled. Rotate the manual lever 601, thereby driving the reel 602 to rotate, the limit block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com