A high-efficiency antibacterial and aldehyde-removing composite additive and its preparation method and application

A compound additive and high-efficiency technology, applied in paints, coatings, anti-fouling/underwater coatings containing biocides, etc., can solve the problems of poor aging resistance of paint films, increased costs, and formation of catalytic sites, etc., to achieve good Anti-aging effect, inhibition of catalytic degradation, effect of increasing catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

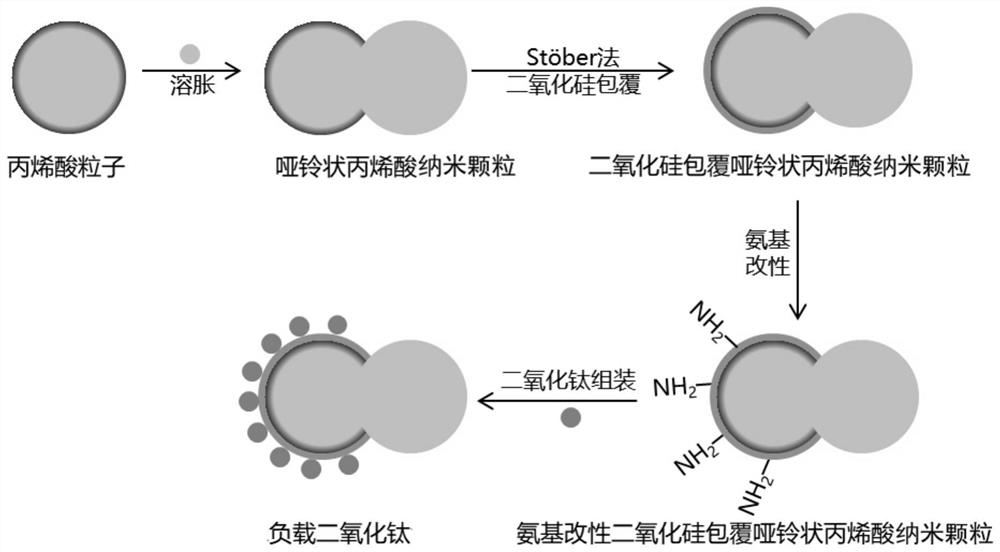

[0054] The present invention is applied to materials such as coatings, and titanium dioxide as an additive can be more exposed to the air to improve its catalytic efficiency. Embodiments are provided to provide a high-efficiency antibacterial and aldehyde-removing composite additive, which is a composite particle.

[0055] Composite particles are mainly composed of acrylic acid particles and silica particles, the silica particles are loaded with titanium dioxide, and acrylic acid particles are mainly polymerized from acrylic monomers;

[0056] The key point of this embodiment lies in the poor hydrophilicity of the acrylic particles and the good hydrophilicity of the silica particles, so that the composite particles have a function similar to that of a giant surfactant. And the silica particle end of the supported titanium dioxide tends to migrate to the gas-liquid surface, so that the active component titanium dioxide is more exposed to the air after film formation, thereby imp...

Embodiment approach 2

[0066] The embodiment of the present invention specifically provides a preparation method of a high-efficiency antibacterial and aldehyde-removing composite additive in the embodiment, which includes the following steps: the surface of the acrylic acid particles coated with organic silicon is subjected to monomer swelling, After the method of synthetic treatment, add titanium dioxide to absorb and obtain the composite additive.

[0067] It also includes the steps of:

[0068] Synthesis of acrylic particles coated with silicone on the surface of S1:

[0069] S11 Stir and mix water, S25, FSL 707, acrylic acid, methyl methacrylate and butyl acrylate to obtain the first pre-emulsion;

[0070] S12 Mix water, S25, FSL 707, N-10, acrylic acid, VeoVa10, silicone monomer KH570, methyl methacrylate, butyl acrylate and isooctyl acrylate to obtain the second pre-emulsion;

[0071] S13 Stir and mix water, sodium bicarbonate, S25, and FSL 707, add the first pre-emulsion and ammonium pers...

Embodiment approach 3

[0080] This embodiment also provides the application of the above-mentioned high-efficiency antibacterial and aldehyde-removing compound additive in interior wall paint, and the addition amount of the high-efficiency antibacterial and aldehyde-removing compound additive in the interior wall paint is more than 0.05%.

[0081] It includes the following components by weight:

[0082] 10-20 parts of pure acrylic emulsion;

[0083] 30-50 parts of water;

[0084] High-efficiency antibacterial and aldehyde-removing composite additive 0.1 part;

[0085] 0.1-1 part of pH regulator;

[0086] Coalescing aid 0.5-2 parts.

[0087] Optionally, it also includes more than one of the following components in the following parts by weight:

[0088] Thickener 0.5-2 parts;

[0089] 0.5-2 parts of wetting and dispersing agent;

[0090] 0.1-1 part of defoamer;

[0091] 0.1-1 part of pH regulator;

[0092] 30-60 parts of pigments and fillers;

[0093] Antiseptic bactericide 0.1-1 part.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com