Essence extraction device for laundry detergent production

A technology of extraction device and laundry liquid, which is applied in the directions of essential oils/fragrance, fat generation, etc., can solve the problems of affecting the efficiency and quality of extraction, and the mixing of fragrance raw materials is not uniform enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

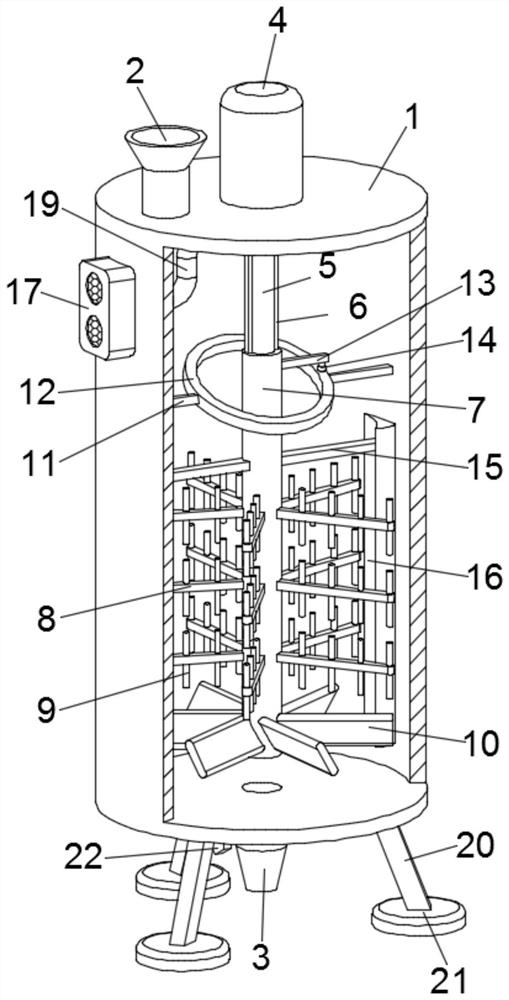

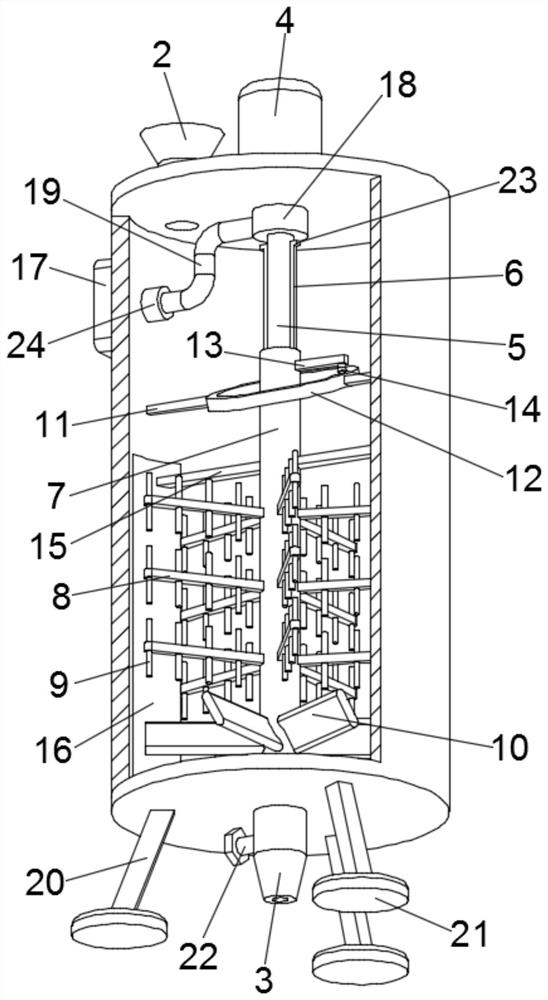

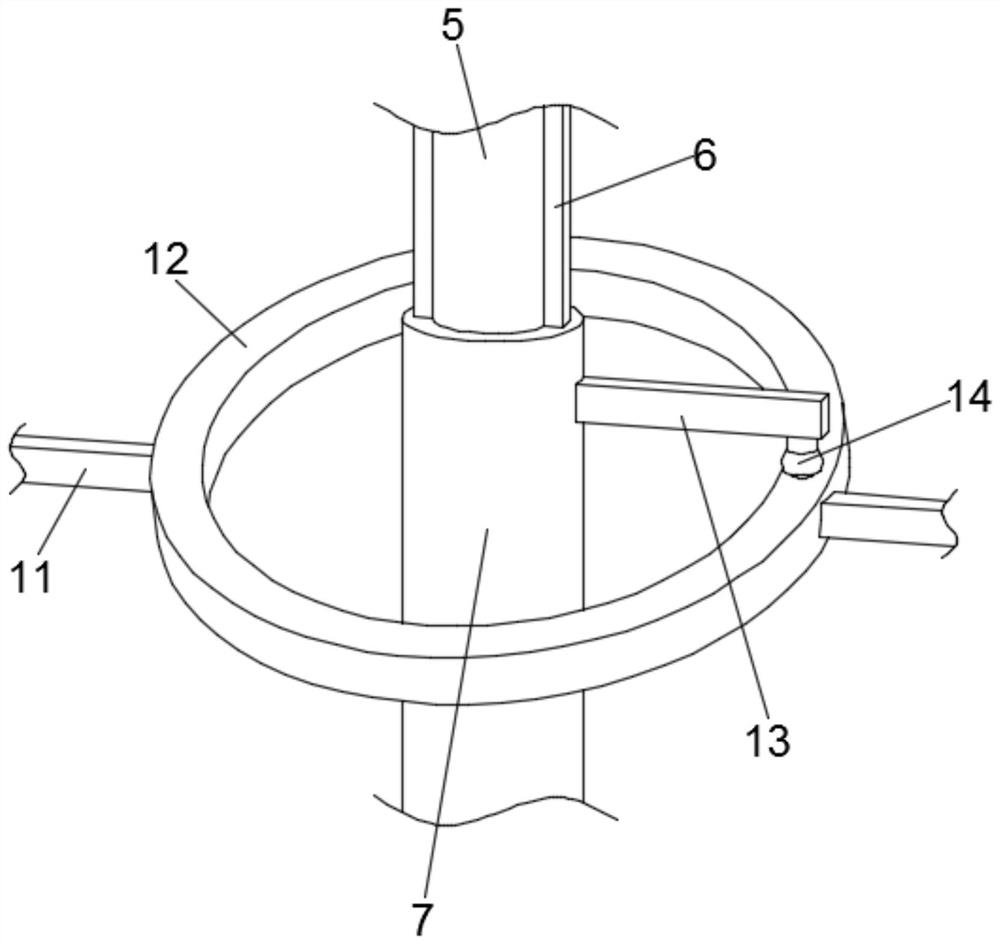

[0022] see Figure 1-3 , an essence extraction device for laundry liquid production, comprising a tank body 1, an upper end of the tank body 1 is provided with a feed port 2, a discharge pipe 3 is installed at the bottom, and a driving motor 4 is fixedly installed on the top of the tank body 1 , the output end of the drive motor 4 is rotated and installed with an inner sleeve 5 vertically extending into the tank body 1, and the outer wall of the inner sleeve 5 is vertically provided with a clip 6, and the outside of the clip 6 is vertically movable The outer sleeve 7 is sleeved, and the outer sleeve 7 is evenly distributed with several rows of main pipes 8 communicating with the inside of the outer sleeve 7. The main pipe 8 is connected with a number of branch pipes 9, and the bottom of the outer sleeve 7 is evenly distributed in the circumferential direction. A plurality of dials 10 are arranged; the inner wall of the tank body 1 is fixedly connected with a slanted guide ring...

Embodiment 2

[0032] An essence extraction device for washing liquid production, comprising a tank body 1, a feed inlet 2 is provided at the upper end of the tank body 1, a discharge pipe 3 is installed at the bottom, and a driving motor 4 is fixedly installed on the top of the tank body 1, The output end of the drive motor 4 is rotatably installed with an inner sleeve 5 that vertically extends into the tank body 1, and the outer wall of the inner sleeve 5 is vertically provided with a clamping strip 6, and the external vertical movable sleeve of the clamping strip 6 is An outer sleeve 7 is provided, and the outer sleeve 7 is evenly distributed with several rows of main pipes 8 communicating with the inside of the outer sleeve 7. The main pipe 8 is connected with a number of branch pipes 9, and the bottom of the outer sleeve 7 is evenly distributed in the circumferential direction. There are several dials 10; the inner wall of the tank body 1 is fixedly connected with a slanted guide ring 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com