Special slag salvaging equipment for hot galvanizing

A technology of hot-dip galvanizing and equipment, applied in hot-dip galvanizing process, coating, metal material coating process and other directions, can solve the problem that the bottom of the slag shovel cannot be stabilized, the human body is consumed, and the slag is not thoroughly enough, etc. problem, to improve the efficiency of slag fishing, reduce physical consumption, and achieve the effect of sufficient slag fishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

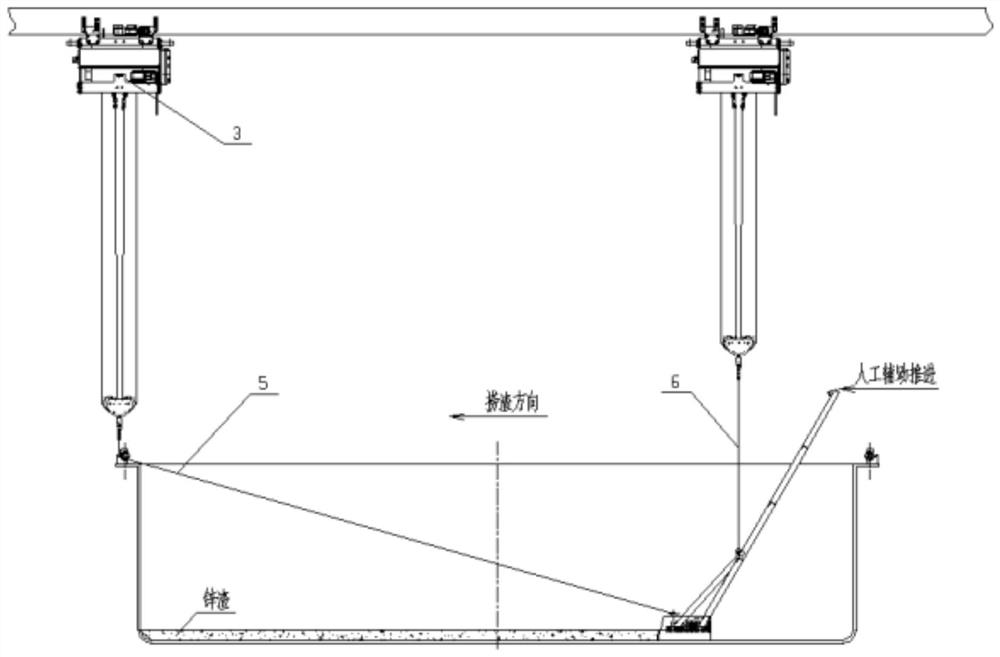

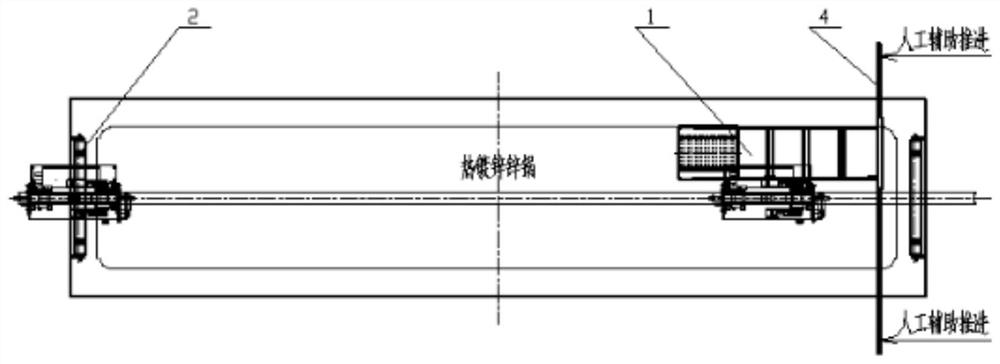

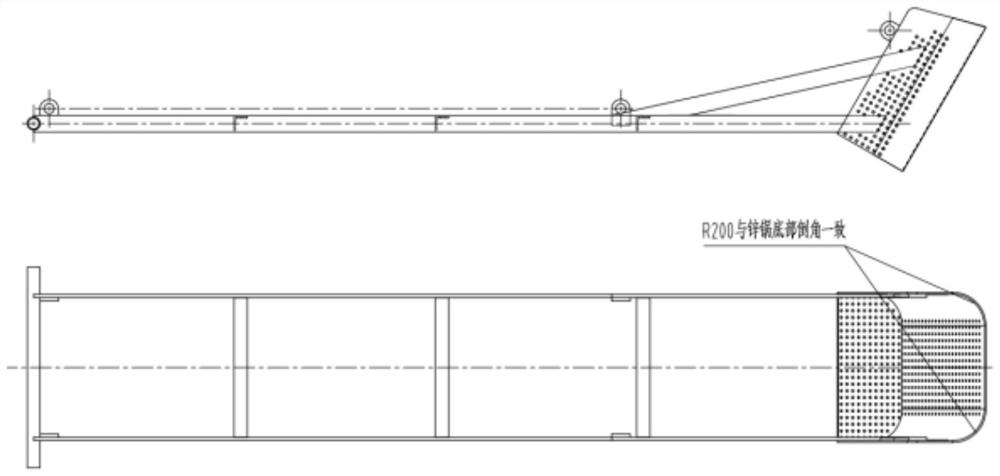

[0027] Embodiment: the action of scooping up zinc slag: the action of scooping up zinc slag ( figure 1 , 2 ), first hang the slag scoop 1 with one end of the main lifting chain 5 and the auxiliary lifting chain 6 as shown in the figure, and then fix the other ends of the main lifting chain 5 and the auxiliary lifting chain 6 on the slag removing trolley 3 (2 sets in total) On the hook, the middle part of the main hoisting chain 5 needs to go around the guide roller 2 before bolting; start the slag removal trolley for 3 walks, transport the slag removal shovel 1 to the top of the zinc pot, and drop the slag removal shovel 1 into the zinc pot ( slag starting position), such as figure 1 The bottom of the slag shovel is in contact with the bottom of the pot; the end of the slag shovel is inserted into the slag shovel push rod 4, and the installation of the slag removal equipment is completed. During slag removal operation, ( figure 1 In ), the slag trolley on the left is lifted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com