Municipal engineering sewage pipe network construction device and construction method

A technology of sewage pipe network and construction device, which is applied in the directions of water supply device, sewage removal, sewer pipeline system, etc., can solve the problems of low construction efficiency, long length and large weight of double-wall corrugated pipe, and achieve stable head-to-tail connection and improve Construction efficiency and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-4 The application is described in further detail.

[0040] The embodiment of the present application discloses a municipal engineering sewage pipe network construction device.

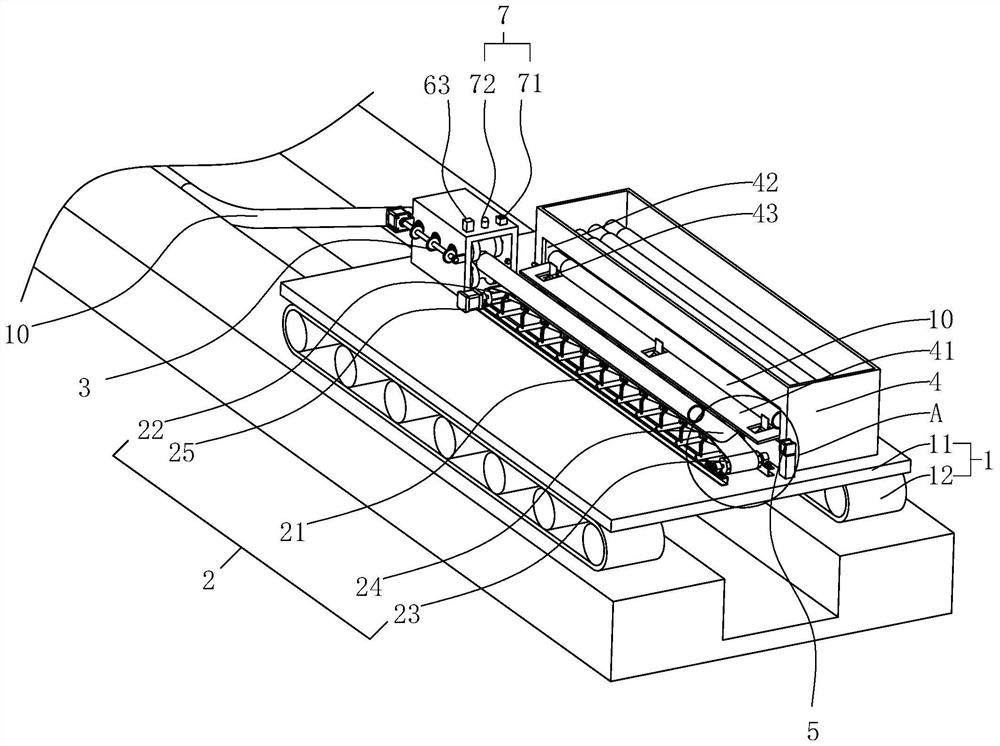

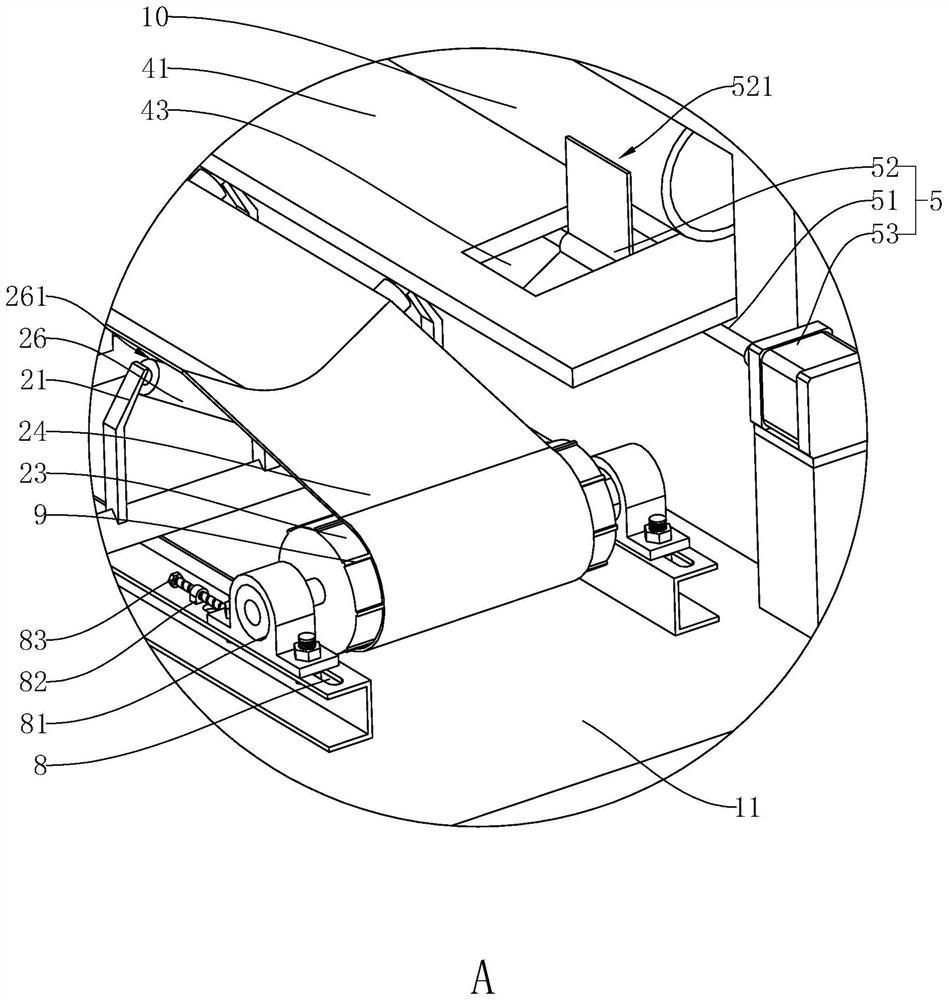

[0041] refer to figure 1 The municipal engineering sewage pipe network construction device includes a traveling mechanism 1. The traveling mechanism 1 includes a workbench 11 and two crawler wheels 12. The workbench 11 is in a rectangular plate-like structure, and the workbench 11 is arranged across the trench directly above the trench. , two crawler wheels 12 are respectively located on both sides of the groove, and two crawler wheels 12 are respectively arranged on the bottom of both sides of the workbench 11, so as to drive the workbench 11 to advance along the extending direction of the groove right above the groove.

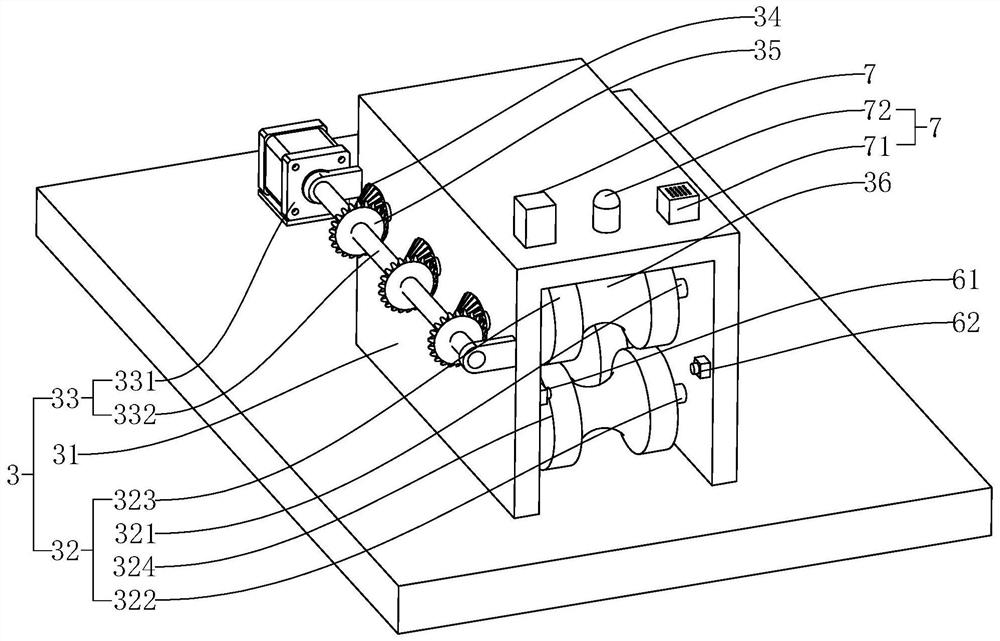

[0042] The top surface of the workbench 11 is provided with a first transmission mechanism 2 and a second transmission mechanism 3, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com