Laminated rubber and metal elastic bearing

A technology of laminated rubber and elastic bearings, applied in the direction of flexible bearings, bearings, bearing components, etc., can solve the problem of low fatigue life of spherical rubber bodies, meet the requirements of torsional fatigue performance, high torsional capacity, and improve torsional fatigue performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

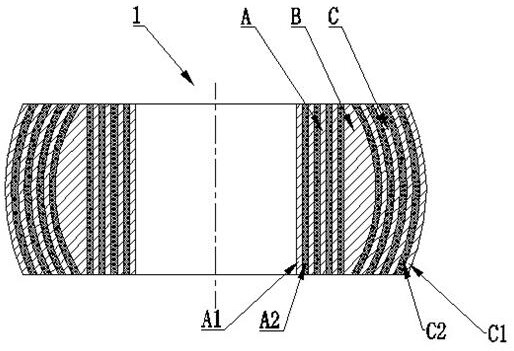

[0048] Laminated rubber 1 of the present invention such as figure 1 Shown: including: a cylindrical part A and a spherical part C; the cylindrical part A is composed of a number of cylindrical metal spacers A1 and a cylindrical rubber layer A2 at intervals; the spherical part C is composed of a number of spherical metal spacers C1 and a spherical rubber layer C2 is stacked at intervals; the spherical part C is connected to the cylindrical part A through a transition metal spacer B.

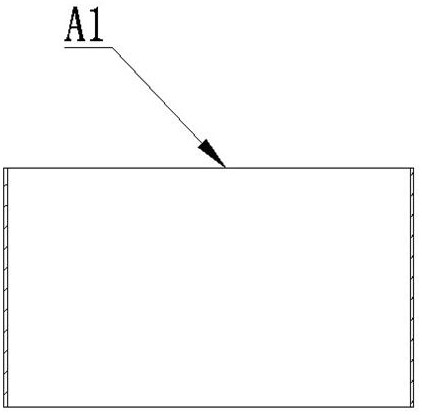

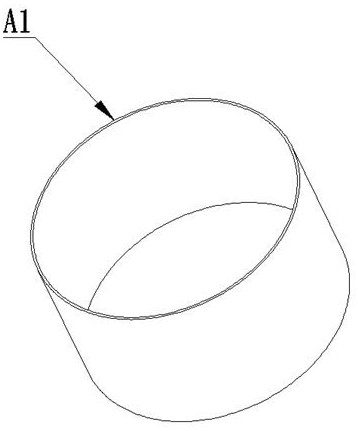

[0049] Cylindrical metal spacer A1 such as Figures 2 to 3 Shown: Cylindrical metal spacers A1 are machined from metal pipes / or metal rods, and the diameters of each layer of cylindrical metal spacers A1 are different. Cylindrical metal spacers A1 and cylindrical rubber layers A2 with different diameters are like Russian nesting dolls Laminated and bonded at interv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com