Body-in-white torsional fatigue testing system and method thereof

A torsional fatigue and testing system technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of sheet metal parts and solder joints prone to fatigue, seam welding, and solder joint open welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

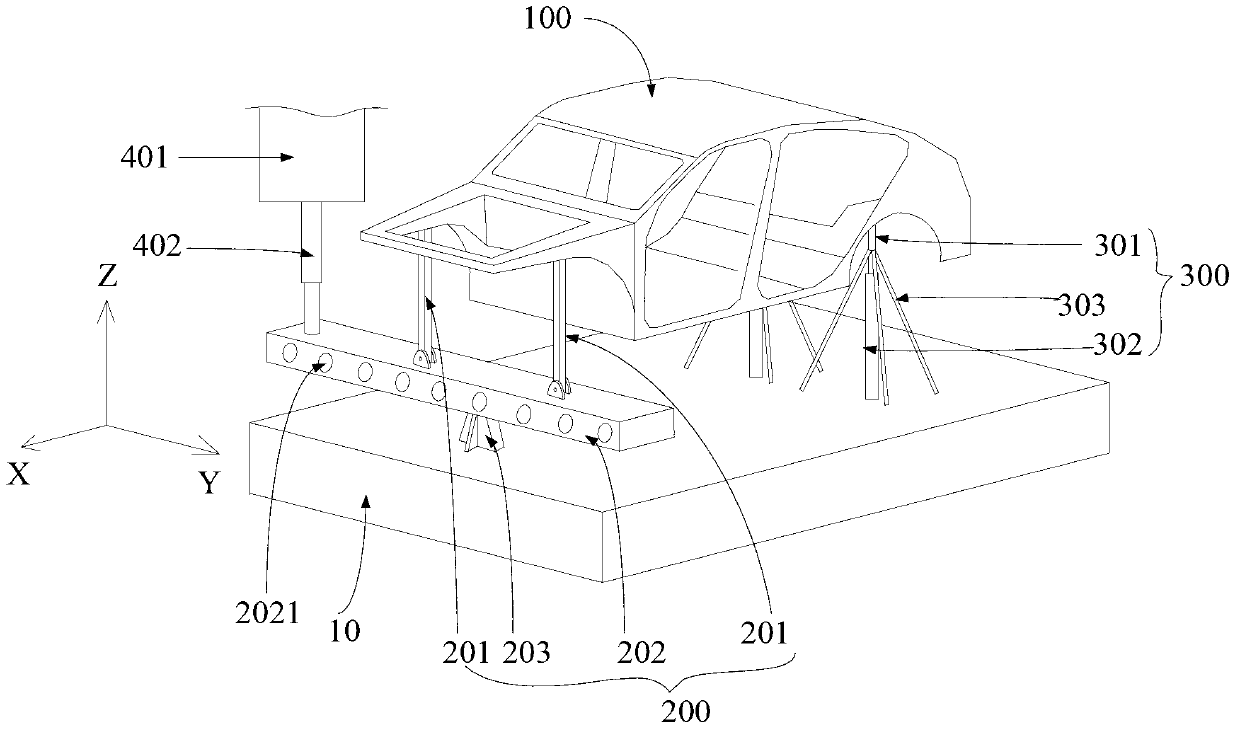

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0036] The body-in-white torsional fatigue test system provided by the present invention mainly includes two major components: a constraint subsystem and a loading subsystem. The function of the body to apply loads.

[0037] Specifically, such as figure 1 As shown, the constraint subsystems in the body-in-white torsional fatigue test system provided in this embodiment include:

[0038] a front shock absorber seat pedestal 200, used to support the first end of the body-in-white 100, and can drive the body-in-white 100 to twist; and,

[0039] A rear shock absorber seat pedestal 300 is used to support the second end of the body in white 100 .

[0040] And as figure 1 As shown, the loading subsystem in the body-in-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com