Control method of intelligent traceability tracking system formotorcycle engine cylinder body

An engine block and tracking system technology, applied in the field of traceability tracking system, can solve the problems such as the inability to realize the tracking and monitoring of the production process and the different information of paper products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

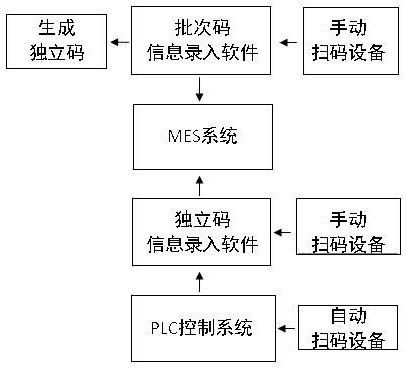

[0056] A control method for an intelligent traceability tracking system of a motorcycle engine cylinder, the steps of which include:

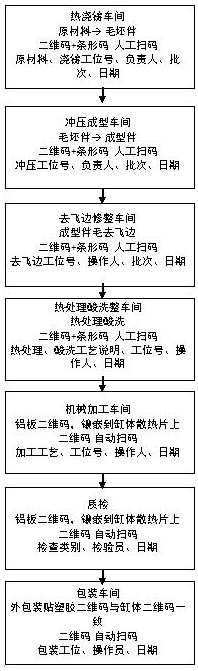

[0057] (1) Print paper codes for each batch of products. There are batch QR codes and bar codes on the paper codes. The batch QR codes are associated with bar codes for summarizing and contacting cylinder information. The same batch The cylinders share a batch QR code.

[0058] (2) In the hot casting workshop, the user pre-enters the hot casting information associated with the batch QR code of this batch. The hot casting information includes raw materials, casting station number, person in charge, batch, and date information; when raw materials When processing into rough parts, the user scans the batch QR code and logs in the account password to obtain the pre-filled hot casting information, and scans the barcode with a handheld scanning device to obtain the batch number; if the pre-filled information is correct, click to enter the information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com