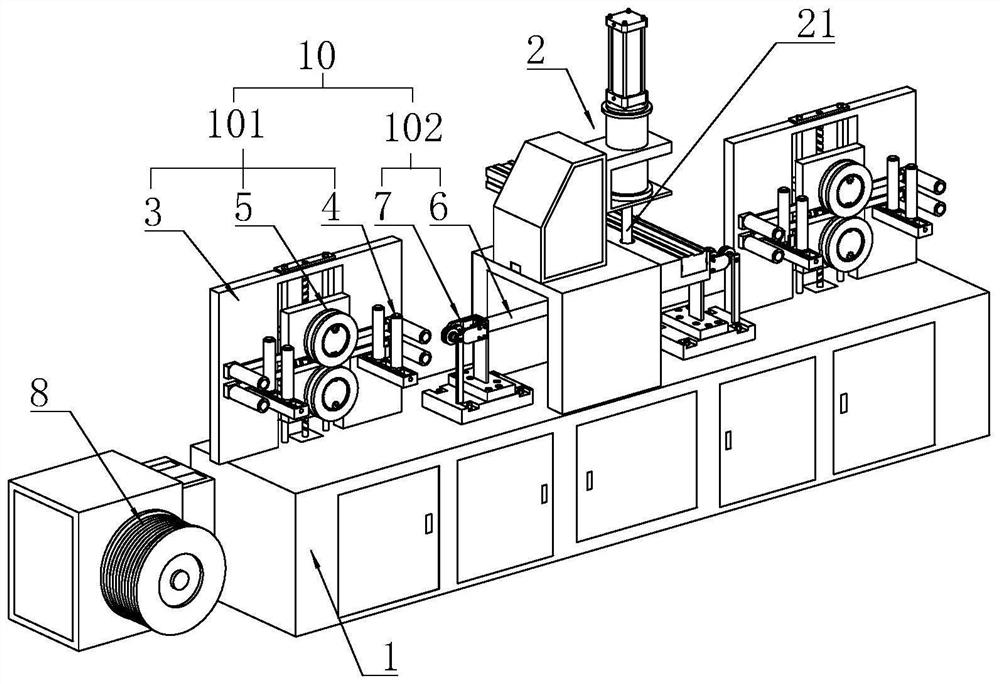

Automatic cable metering and code-spraying production line

A production line and coding technology, which is applied in the direction of marking conductors/cables, cable/conductor manufacturing, circuits, etc., can solve problems affecting the quality of coding, cable deformation, etc., to improve flatness, reduce extrusion deformation, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

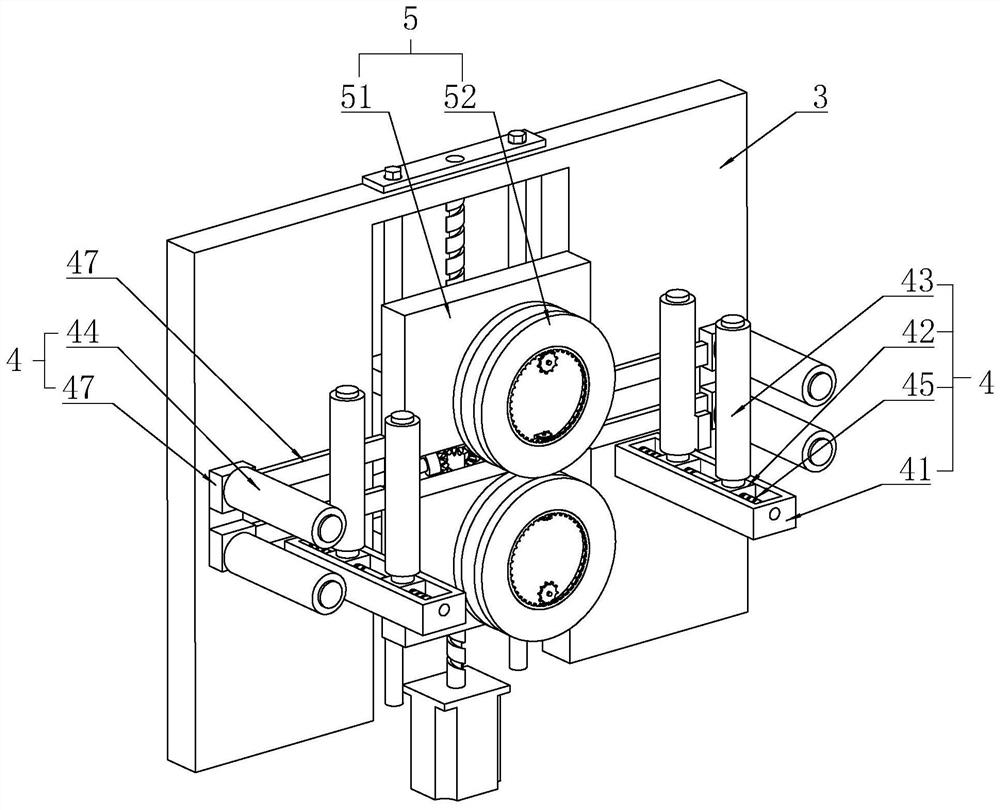

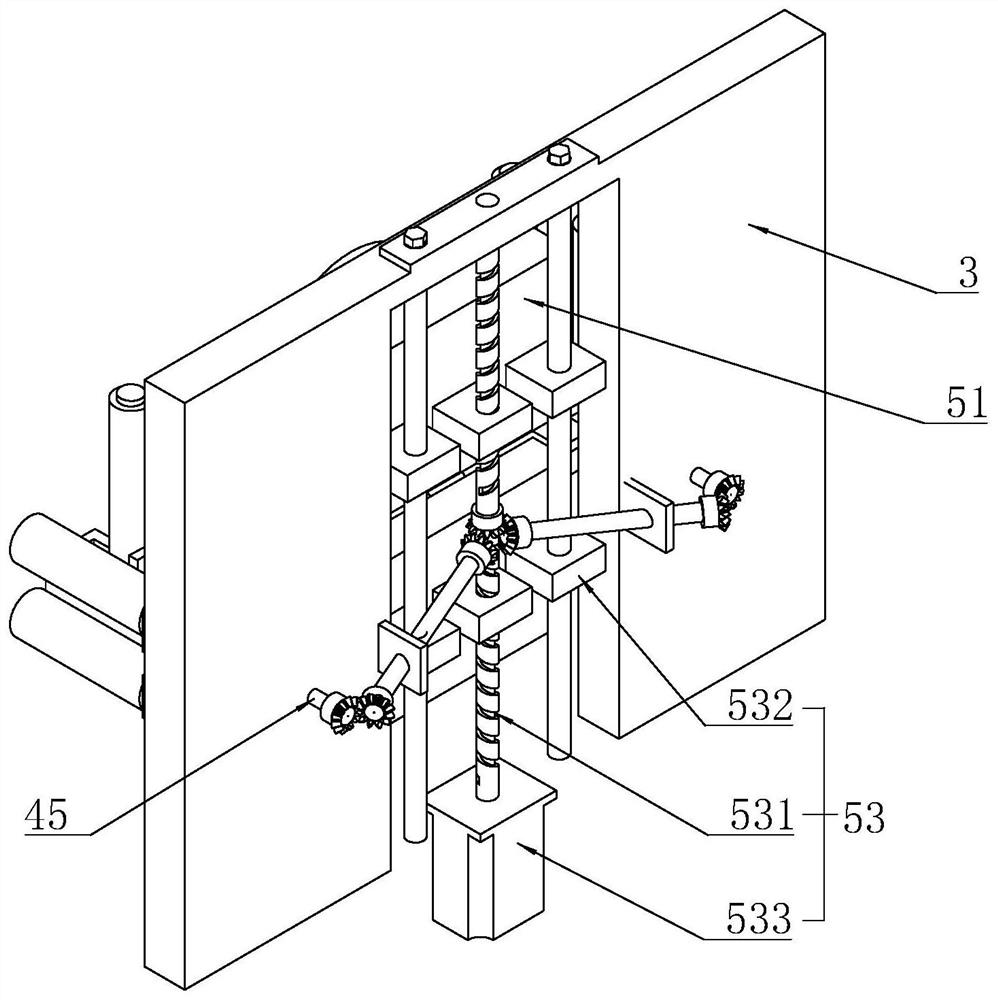

Method used

Image

Examples

Embodiment 2

[0052] Embodiment 2, with reference to Figure 7 , the difference from Embodiment 1 is that the wire conduit 6 passes directly under the inkjet printer 2, and the wire conduit 6 is divided into a first pipe part 6867 and a second pipe part according to upstream and downstream, and the inner pipe 61 is located in the first pipe In the part 6867, a spray groove 69 facing the nozzle 21 of the inkjet printer 2 is opened on the side wall of the second pipe part, and the spray groove 69 communicates with the inner cavity of the second pipe part. The spray head 21 can spray code on the cable 8 in the second pipe part through the spray groove 69 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com