Inductor and forming method thereof

A technology of inductance and magnetic core, applied in the field of inductance, can solve the problem of high noise, achieve the effect of low noise, reduce DCR, and improve current resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

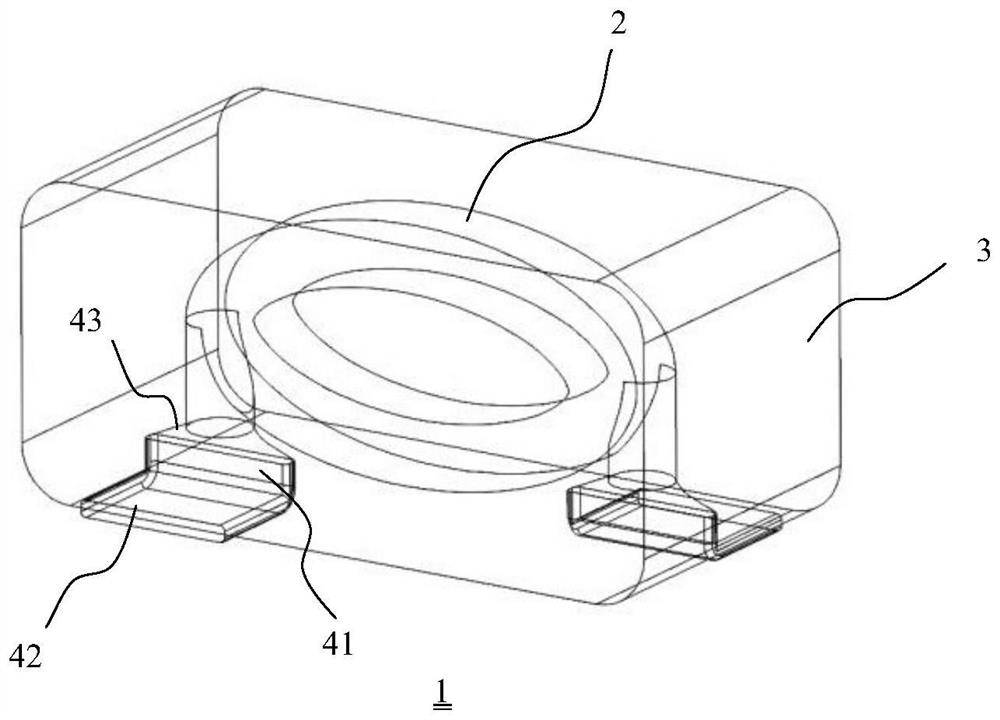

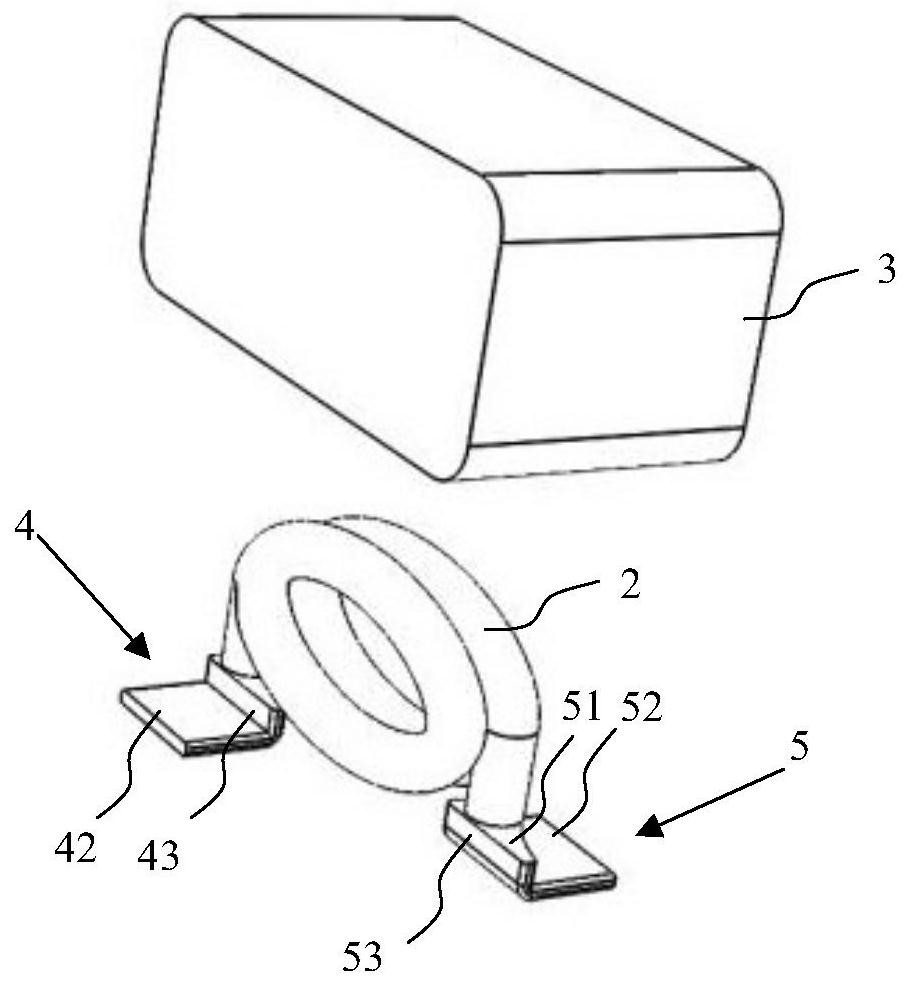

[0025] The invention discloses an inductor 1, which can be applied to high-end graphics card equipment to meet the requirements of the market for high current resistance, low loss and low noise. Specifically, figure 1 A schematic diagram of the inductor 1 of the present invention is disclosed, including a coil 2 and a magnetic core 3, the magnetic core 3 is a rectangular parallelepiped structure, the coil 2 is accommodated inside the magnetic core 3, and the magnetic core 3 with a rectangular parallelepiped structure can be used on a PCB More inductors 1 can be accommodated in a unit area, increasing power density.

[0026] The magnetic core 3 is made of magnetic materials, usually made of amorphous and carbonyl powders in a certain ratio and optimally configured.

[0027] The main part of the coil 2 is wound into an oval structure, which has a first end and a second end, and the first end of the coil 2 and the second end of the coil 2 are respectively connected to terminals. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com